Sealing apparatus, bipolar battery and single battery

A sealing device and sealing end cap technology, applied in sealing materials, lead-acid batteries, battery pack components, etc., can solve the problems of reducing battery discharge performance, battery discharge voltage, and battery temperature, so as to improve discharge performance and The effect of service life, reducing internal resistance and suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

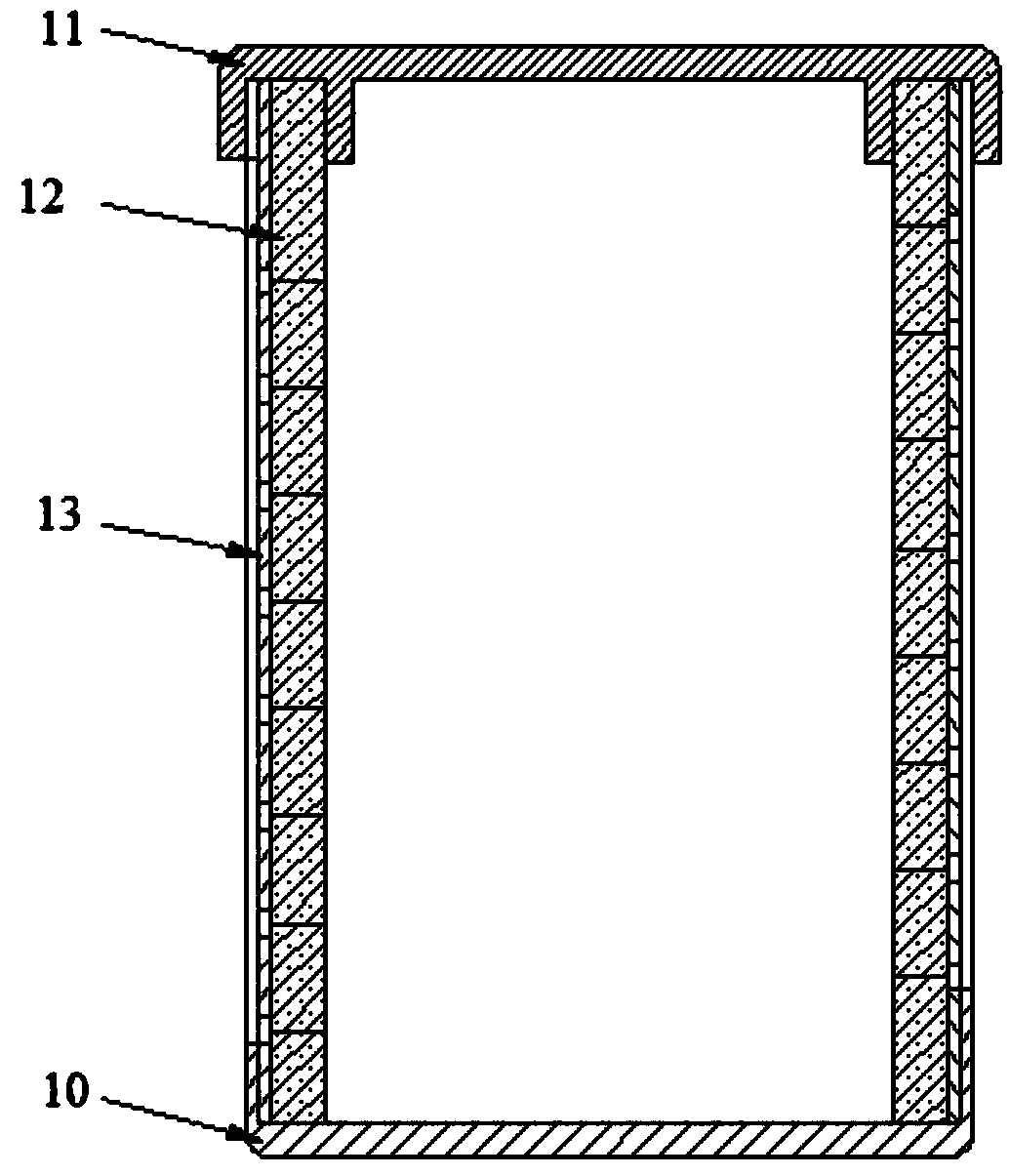

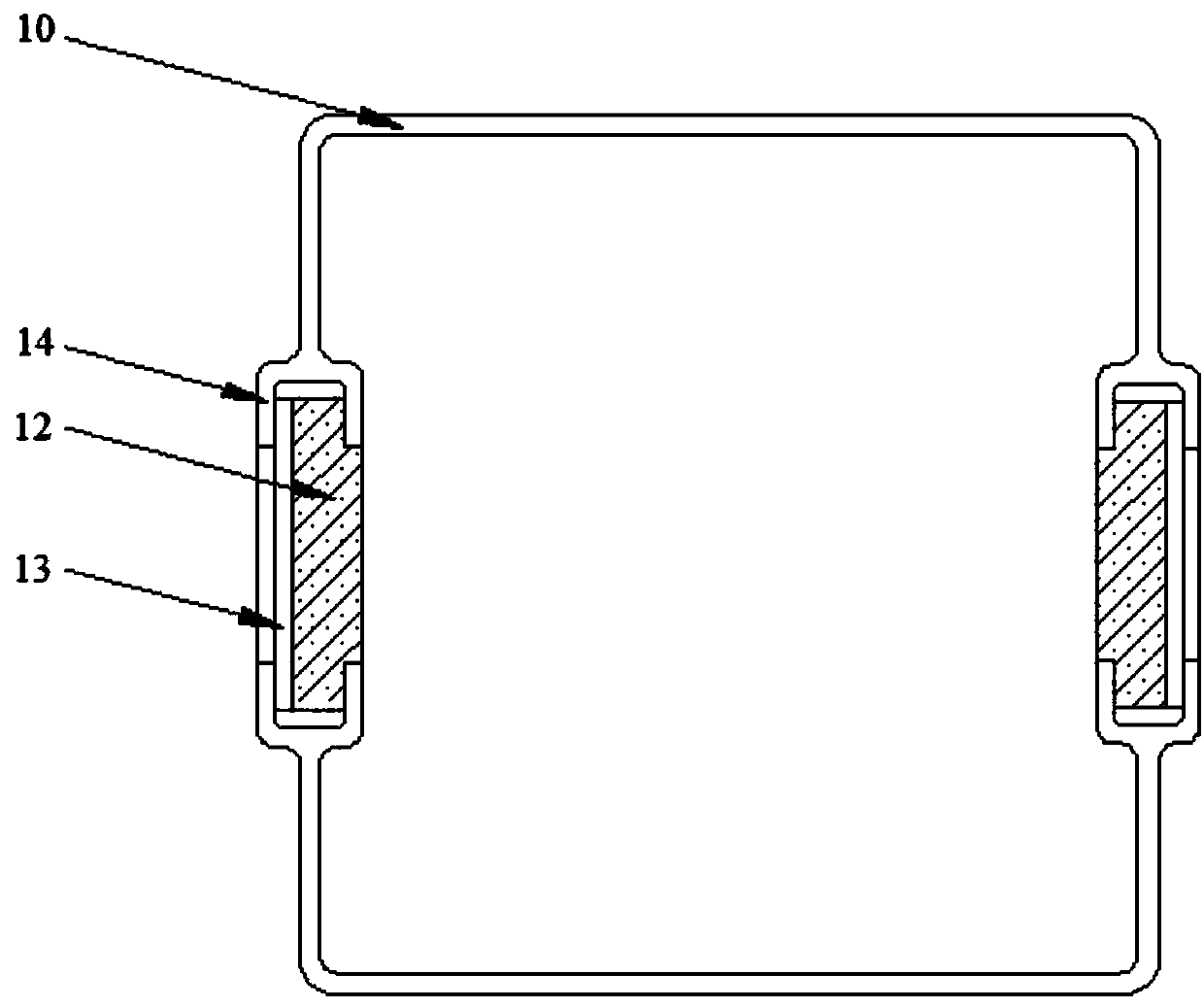

[0042] Such as figure 2 and image 3 As shown, a sealing device for a battery plate, the sealing device 1 includes: a tank body 10, a sealing upper cover 11 covering the tank body, and a soft adsorption strip 12, wherein,

[0043] Described groove body 10 comprises two oppositely arranged groove walls, and the two ends of each described groove wall are all provided with a groove wall positioning groove 14, and the groove of described groove wall positioning groove 14 of the same end of two described groove walls The mouths are opposite, and the end face of the groove wall positioning groove 14 is flush with the notch of the groove body 10 .

[0044]The soft adsorption strip 12 is adsorbed with a liquid adhesive and solidified, and the two ends of the soft adsorption strip 12 are embedded in a pair of groove wall positioning grooves 14 opposite to the notch, and multiple layers are embedded in the grooves. The soft adsorption strip 12 in the wall positioning groove 14 and th...

Embodiment 2

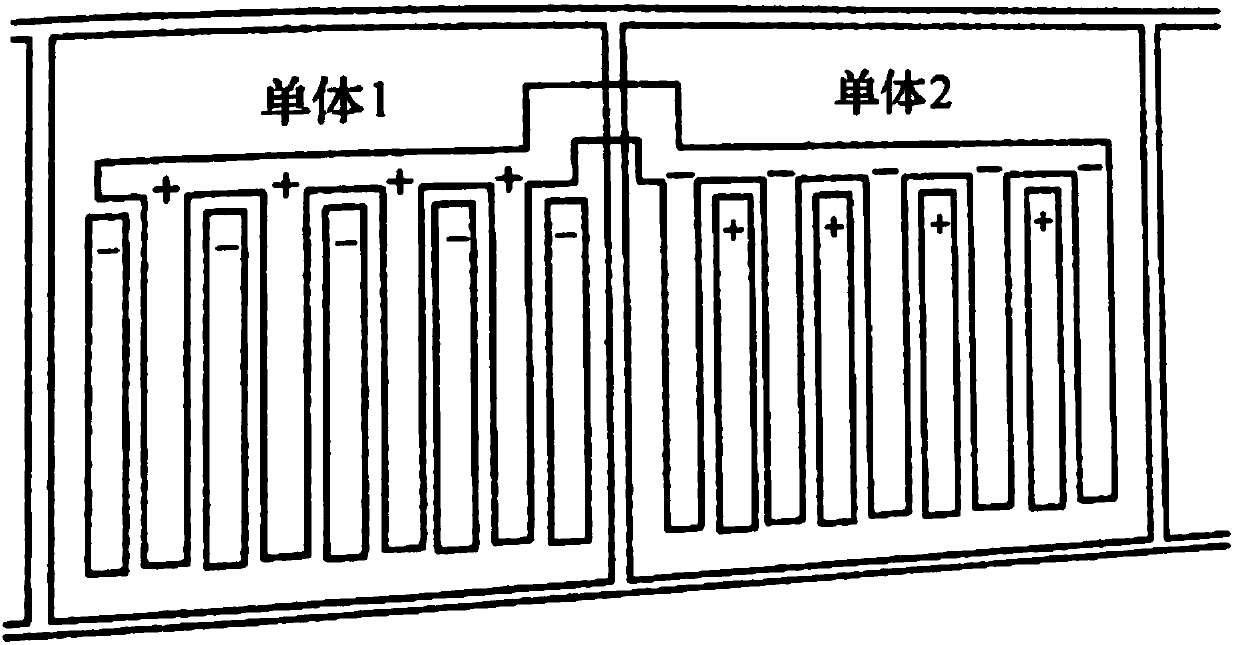

[0050] Such as Figure 5 and Figure 6 As shown, a bipolar battery includes: the sealing device 1, the positive plate 2, the bipolar plate 3, the negative plate 4 and the separator 5 in multiple embodiments 1, wherein,

[0051] The sealing device 1 includes positive sealing devices and at least one bipolar sealing device connected in series in sequence, and the sealing end caps between adjacent sealing devices 1 are the same sealing end cap, and each of the sealing devices 1 The sealed space is filled with electrolyte;

[0052] The sealing device matched with the positive electrode plate 2 is the positive sealing device, a plurality of the positive electrode plates 2 are parallel to the bottom of the groove and stacked in the groove body of the positive sealing device 1, each of the One end of the positive plate 2 is a positive plate extension 21, and the other end of the positive plate 2 is a positive plate built-in end 22. Each of the positive plate extensions 21 is connec...

Embodiment 3

[0071] Such as Figure 7 and Figure 8 As shown, a single battery, the single battery includes: the sealing device 1 described in embodiment 1, the positive plate 2, the negative plate 4 and the separator 5, wherein,

[0072] One end of each positive plate 2 is a positive plate extension 21, the other end of the positive plate 2 is a positive plate built-in end 22, and one end of each negative plate 4 is a negative plate extension 41. The other end of the plate 4 is the built-in end 42 of the negative plate;

[0073] A plurality of positive plates 2 are parallel to the bottom of the tank and stacked in the tank body of the sealing device 1, and each of the positive plate extensions 21 is absorbed from the adjacent soft material of the sealing end cap on the same side. The gap between the strips 12 protrudes; one negative plate 4 is arranged parallel to the bottom of the groove between two adjacent positive plates 2, and each negative plate extension 41 is drawn from the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com