An exhaust system and device and method for preventing backflow of dust particles

A technology of dust particles and exhaust pipelines, which is applied in the field of semiconductor equipment, can solve problems such as no software control or hardware linkage operation, sudden overload failure, cavity pollution, etc., to facilitate daily maintenance, reduce hardware losses, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

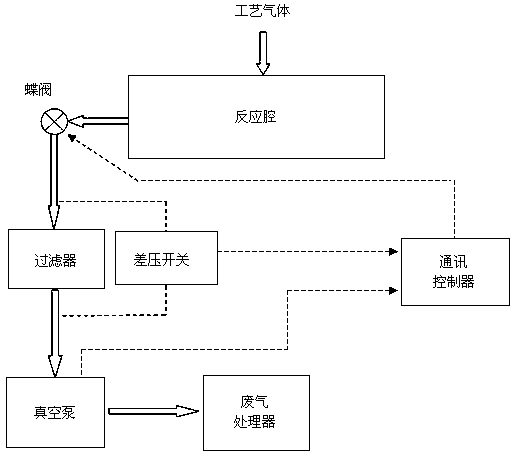

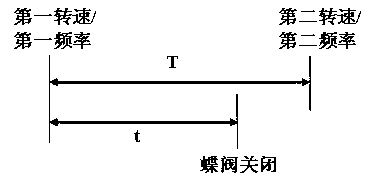

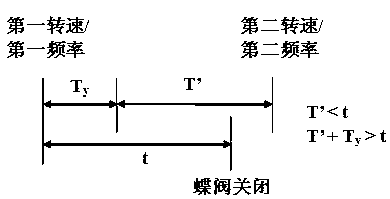

[0021] Such as figure 1 As shown, the present invention provides an exhaust system and a device and method for preventing the backflow of dust particles, which are applicable to any semiconductor equipment with a vacuum reaction chamber, such as MOCVD equipment. The gas outlet of the reaction chamber communicates with an exhaust pipeline, and a butterfly valve, a filter, a vacuum pump, and a waste gas processor are sequentially arranged on the exhaust pipeline.

[0022] The present invention is equipped with a communication controller, which can predict the key information of the possible backflow of dust particles according to the real-time monitoring results of the operation of the vacuum pump and the reaction chamber, and take emergency protection measures to prevent the failure of the vacuum pump or other components. The dust particles flow back into the reaction chamber.

[0023] The communication controller is signal-connected to the monitoring unit of the vacuum pump m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com