A kind of powder alloy material based on polyamide and preparation method thereof

A polyamide powder and powder alloy technology, which is applied in the field of additive manufacturing, can solve the problems affecting the dimensional stability and mechanical properties of the workpiece, the application of powder alloy materials, and the poor dry impact performance of polyamide, etc., to achieve interface bonding Strong force, ensuring stability, and improving powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a polyamide-based powder alloy material, comprising: mixing and stirring the components included in the polyamide-based powder alloy material evenly, passing through a 100-mesh sieve, and drying to obtain a polyamide-based powder alloy material. Amide powder alloy material.

[0035] The present invention will be further described in detail through specific implementation methods below.

Embodiment 1

[0037] (1) 3200g of PA46 powder with an average particle size of 60μm, 800g of PPS powder with an average particle size of 60μm, 30g of nano-silica, 150g of styrene-maleic anhydride powder with an average particle size of 3μm, 10g of 2,6-di-tert-butyl - Add 4-methyl-phenol, 5g 2,2'-ethylenebis(4,6-di-tert-butylphenyl) fluorophosphite into the mixer, mix well, pass through a 100-mesh sieve, 80°C Vacuum drying for 4 hours to obtain PA46 and PPS powder alloy material;

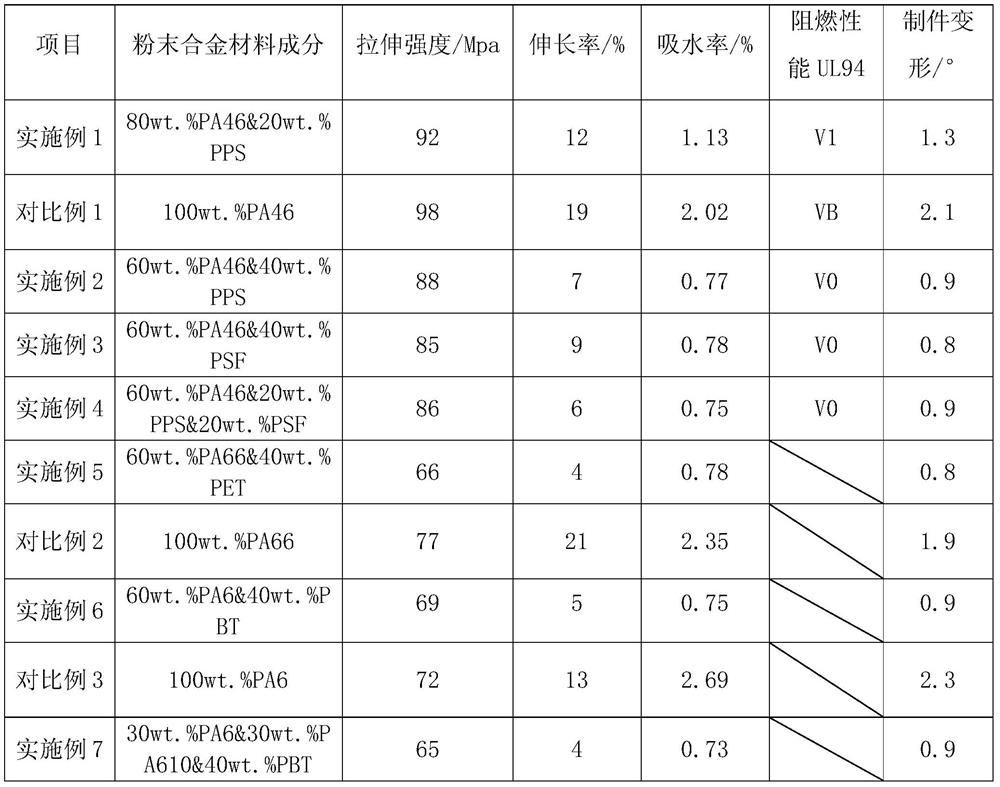

[0038] (2) The above-mentioned powder was sintered on the ST252 selective laser sintering equipment of Hunan Farsoon Hi-Tech, and the performance test of the obtained sintered sample was carried out. The results are shown in Table 1.

Embodiment 2

[0043] (1) 2400g of PA46 powder with an average particle size of 60μm, 1600g of PPS powder with an average particle size of 60μm, 30g of nano-silicon dioxide, 150g of styrene-maleic anhydride with an average particle size of 3μm, and 10g of 2,6-di-tert-butyl- Add 4-methyl-phenol and 5g of 2,2'-ethylenebis(4,6-di-tert-butylphenyl)fluorophosphite into the mixer, mix evenly, pass through a 100-mesh sieve, vacuum at 80°C Dry for 4 hours to obtain PA46 and PPS powder alloy material;

[0044] (2) The above-mentioned powder was sintered on the ST252 selective laser sintering equipment of Hunan Farsoon Hi-Tech, and the performance test of the obtained sintered sample was carried out. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com