Handmade soap and method for preparing same

A technology of handmade soap and transparent soap base, which is applied in the direction of chemical instruments and methods, soap detergents and other compounding agents, skin care preparations, etc., to achieve the effects of slowing down the use speed, alleviating staining problems, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

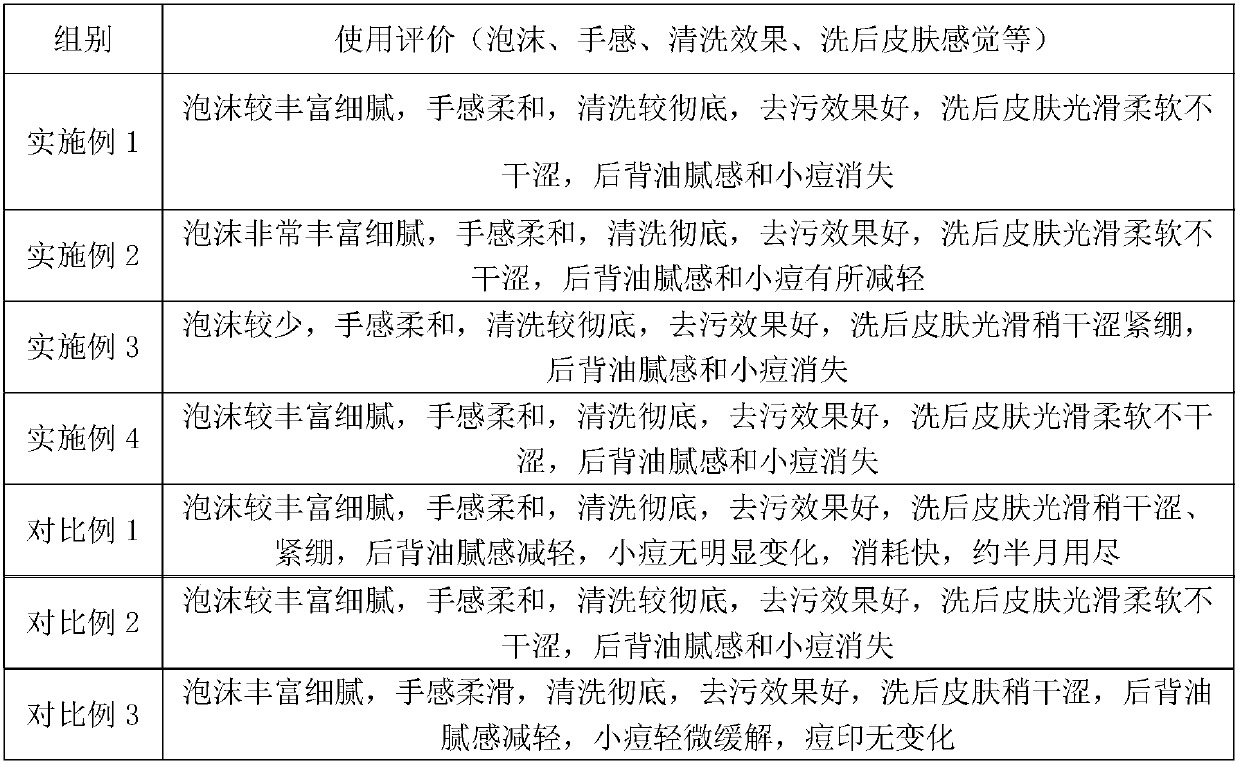

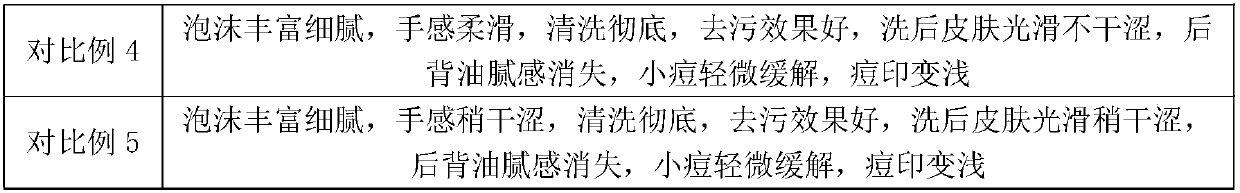

Examples

Embodiment 1

[0030] 1. Formula: 87.9% of transparent soap base, 7% of sapindus liquid, 5% of zeolite, and 0.1% of fulvic acid.

[0031] 2. The production method comprises the following steps:

[0032] In the first step, add 1% activated carbon and 2.5% white clay to the commercially available sapindus liquid for simple decolorization, and filter to obtain the decolorized sapindus liquid;

[0033] The second step is to heat the transparent soap base to melt it completely;

[0034] The third step is to add the mixture of decolorized sapindus liquid, zeolite and fulvic acid into the melted transparent soap base, stir until it is completely uniform, pour it into the mold, and let it stand for cooling;

[0035] The fourth step is to remove the mold after the semi-finished product is completely cooled, and the finished handmade soap is obtained.

Embodiment 2

[0037] 1. Formula: 87.98% of transparent soap base, 10% of sapindus liquid, 2% of zeolite, 0.02% of fulvic acid.

[0038] 2. The production method comprises the following steps:

[0039] The first step is to take the commercially available Sapinberry liquid, add 3% attapulgite for simple decolorization, and filter to obtain the decolorized Sapinberry liquid;

[0040] The second step is to heat the transparent soap base to melt it completely;

[0041] The third step is to add a mixture of decolorized sapindus liquid, zeolite and fulvic acid into the melted transparent soap base, stir while heating, and pour it into a mold after it is completely uniform, and let it stand for cooling;

[0042] The fourth step is to remove the mold after the semi-finished product is completely cooled, and the finished handmade soap is obtained.

Embodiment 3

[0044] 1. Formula: 89.9% transparent soap base, 3% Sapindus liquid, 7% zeolite, 0.1% fulvic acid.

[0045] 2. The production method comprises the following steps:

[0046] In the first step, 5% diatomaceous earth is added to the commercially available Sapindus solution for simple decolorization, and then filtered to obtain the decolorized Sapindus solution;

[0047] The second step is to heat the transparent soap base to melt it completely;

[0048] The third step is to add the mixture of decolorized sapindus liquid, zeolite and fulvic acid into the melted transparent soap base, stir while heating, and pour it into the mold after it is completely uniform, and let it stand for cooling;

[0049] The fourth step is to remove the mold after the semi-finished product is completely cooled, and the finished handmade soap is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com