A kind of hand-made model material and preparation method thereof

A model material and hand-made technology, applied in the field of materials, can solve the problems of product appearance damage, poor durability, slow curing speed, etc., achieve the effect of high fluidity and solubility, reduce the difficulty of operation, and promote the degree of mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

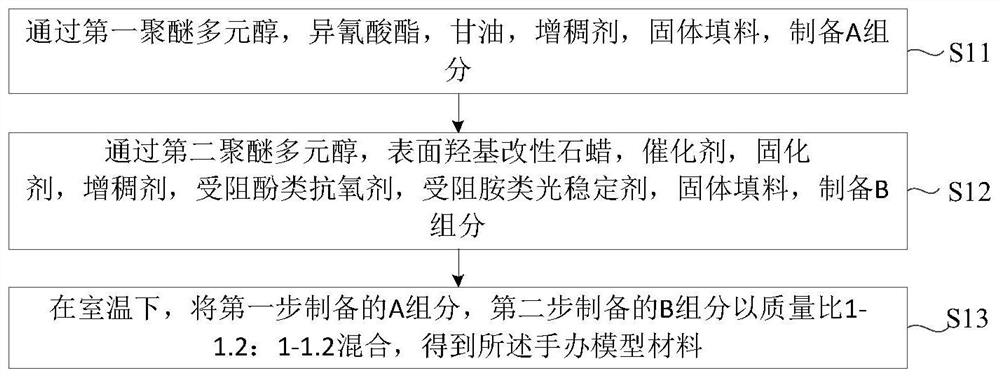

Method used

Image

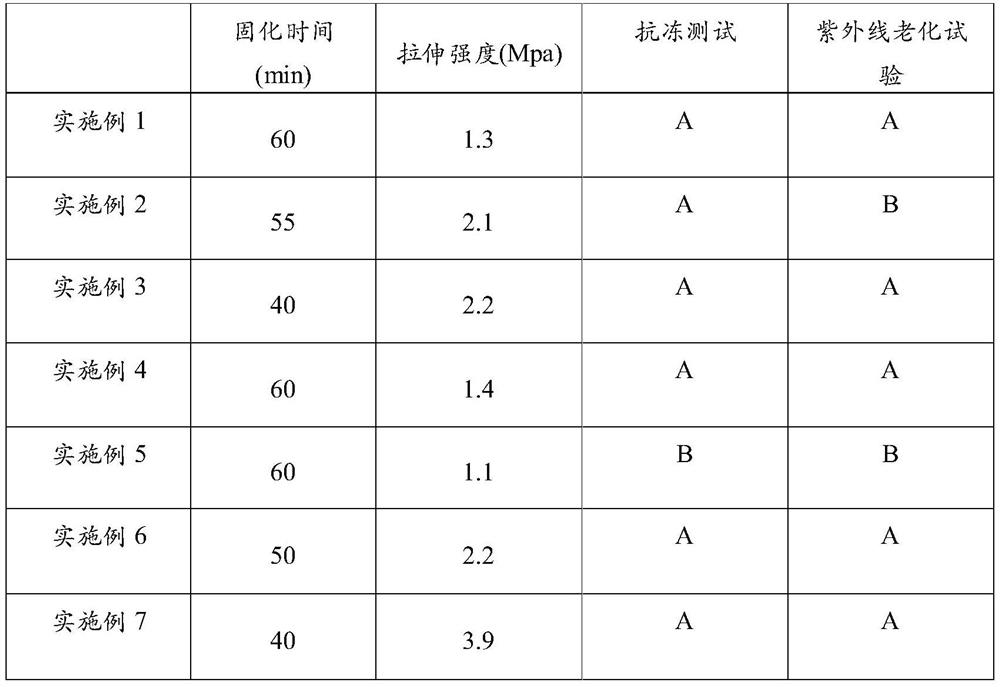

Examples

preparation example 1

[0081] Take 20g of paraffin and heat it to above 60°C, liquefy the paraffin, put it into 50mL of 20wt% hydrogen peroxide, stir and react at 40°C for 15min, quickly transfer it to an ice-water bath and cool it to room temperature, the paraffin is condensed into particles, filtered, washed with water until neutral, and then The modified paraffin wax 1 was obtained by placing the paraffin wax modified by the surface hydroxyl group in a vacuum drying oven at 25-30° C. and drying. After testing, the number of hydroxyl groups on the surface of the modified paraffin wax obtained was 0.132 mmol / g.

preparation example 2

[0083] The operation of this example is similar to that of Example 1, except that the concentration of hydrogen peroxide is 15%wt, the reaction temperature is 60°C, and the reaction time is 5min to obtain modified paraffin 2, and the number of surface hydroxyl groups of the obtained modified paraffin 2 is 0.164 mmol / g.

preparation example 3

[0085]The operation of this example is similar to that of Example 1, except that the concentration of hydrogen peroxide is 5% wt, the reaction temperature is 60° C., and the reaction time is 30 min to obtain modified paraffin 3, and the number of surface hydroxyl groups of the obtained modified paraffin 3 is 0.253 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com