Die cooling water pipe connector

A cooling technology for water pipe joints and molds, which is applied in the direction of pipes/pipe joints/fittings, sleeves/sockets, passing components, etc. It can solve the problems of unable to meet the technical requirements of use, large volume of old-fashioned water pipe joints, inconvenient disassembly and assembly, etc. , to achieve the effect of good sealing effect, simple and reasonable structure, and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

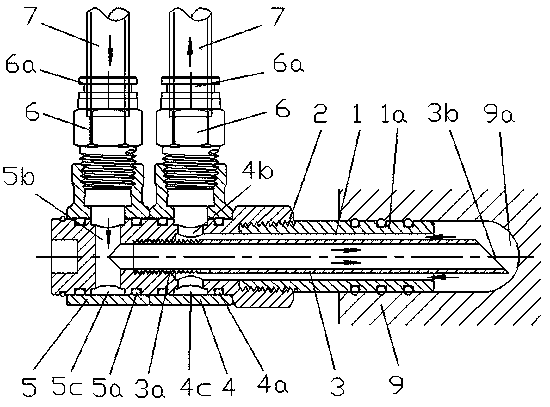

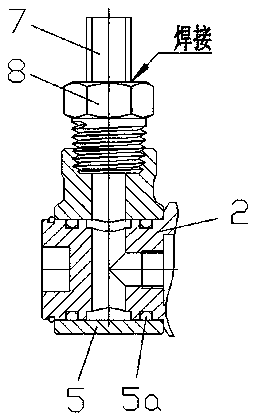

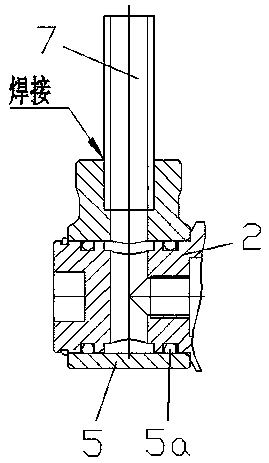

[0013] figure 1 A structural diagram of a mold cooling water pipe joint is shown. In the figure, this mold cooling water pipe joint includes a connecting pipe 1 , a pipe joint body 2 , an inner water inlet pipe 3 , a water outlet jacket type joint 4 and a water inlet jacket type joint 5 . The external thread of one end of the connecting pipe 1 is fixedly connected with the internal thread of the pipe joint body 2 , and the other end of the connecting pipe 1 is connected with the mold 9 in a rotary sealing manner by using three O-rings 1a. The outer thread 3a at one end of the inner water inlet pipe 3 is fixedly connected with the inner thread in the pipe joint body 2 . The pipe joint body 2 is provided with a water outlet annular groove 4c and two water outlet O-rings 4a located on both sides of the water outlet annular groove 4c at the position of the water outlet through hole 4b, and a water inlet annular groove is provided at the position of the water inlet through hole 5b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com