Detection mechanism of robot for detecting corrosion of in-service large crude oil storage tank

A crude oil storage tank, corrosion detection technology, applied in instruments, measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve problems such as detection of storage tank bottoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

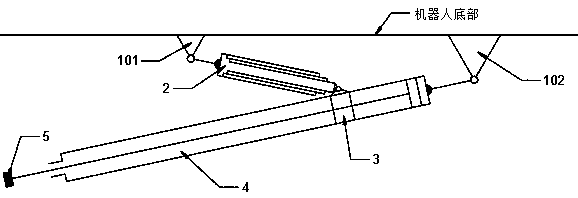

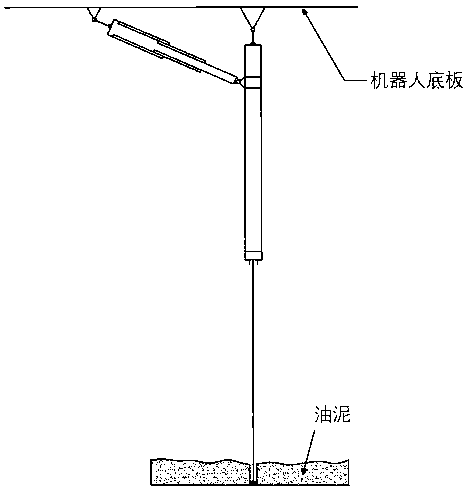

[0022] Such as figure 1 , 2 As shown, the detection mechanism of a large-scale crude oil storage tank corrosion detection robot in service in the present invention includes a left end hinge support (101), a right end hinge support (102), a support rod (2), a connecting piece (3), a detection rod (4), ultrasonic thickness measuring probe (5). The left end hinge support (101) fixes the support rod (2), and the right end hinge support (102) fixes the detection rod (4); the connecting piece (3) connects the support rod (2) and the detection rod (4); the ultrasonic thickness measuring probe (5) fixed on the front end of the detection rod (4). The structure is a retractable structure, and online detection can still be performed when there are obstacles such as heating coils and oil sludge on the bottom of the storage tank. A complete inspection process is as follows: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com