Secondary cell charging method

A charging method and technology for secondary batteries, which are applied in the charging/discharging of secondary batteries, repair/maintenance of secondary batteries, and battery circuit devices, etc., can solve the deterioration of battery cycle life, the influence of cathode structure stability, and the increase of cathode potential, etc. problem, to achieve the effect of improving cycle performance, reducing polarization effect, and reducing polarization potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

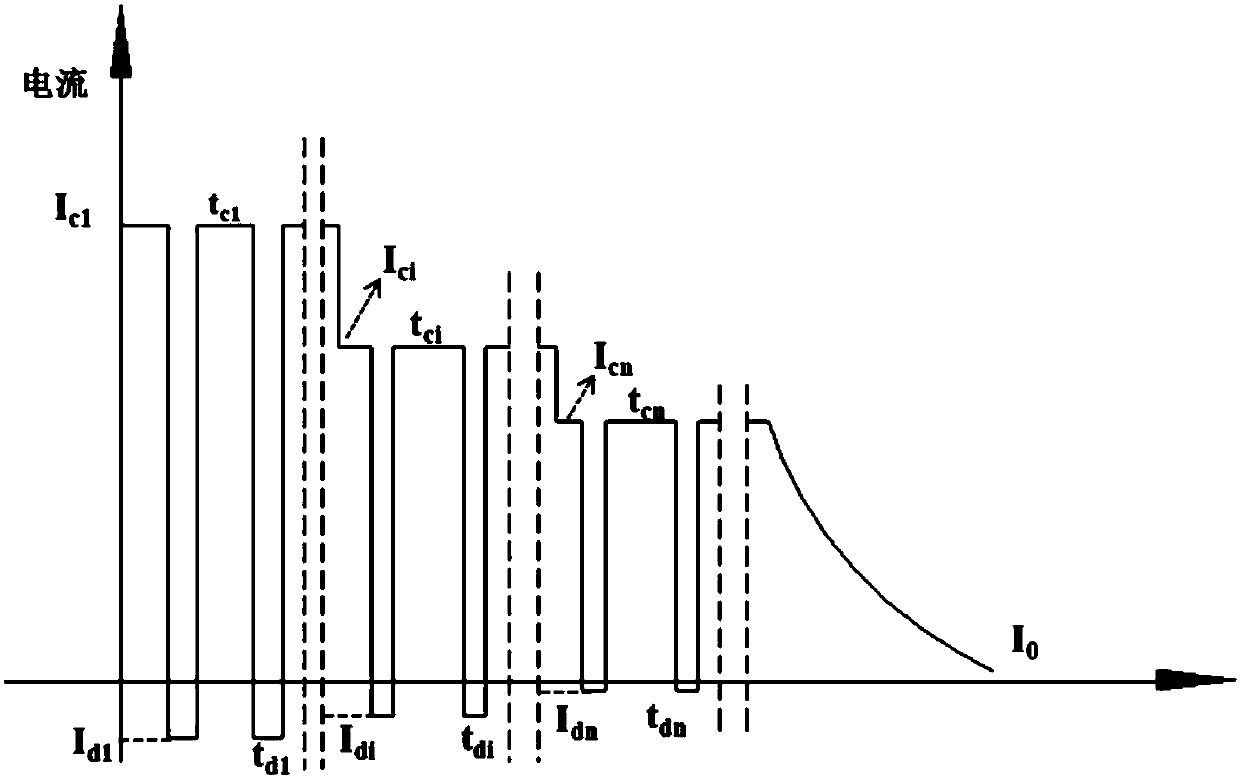

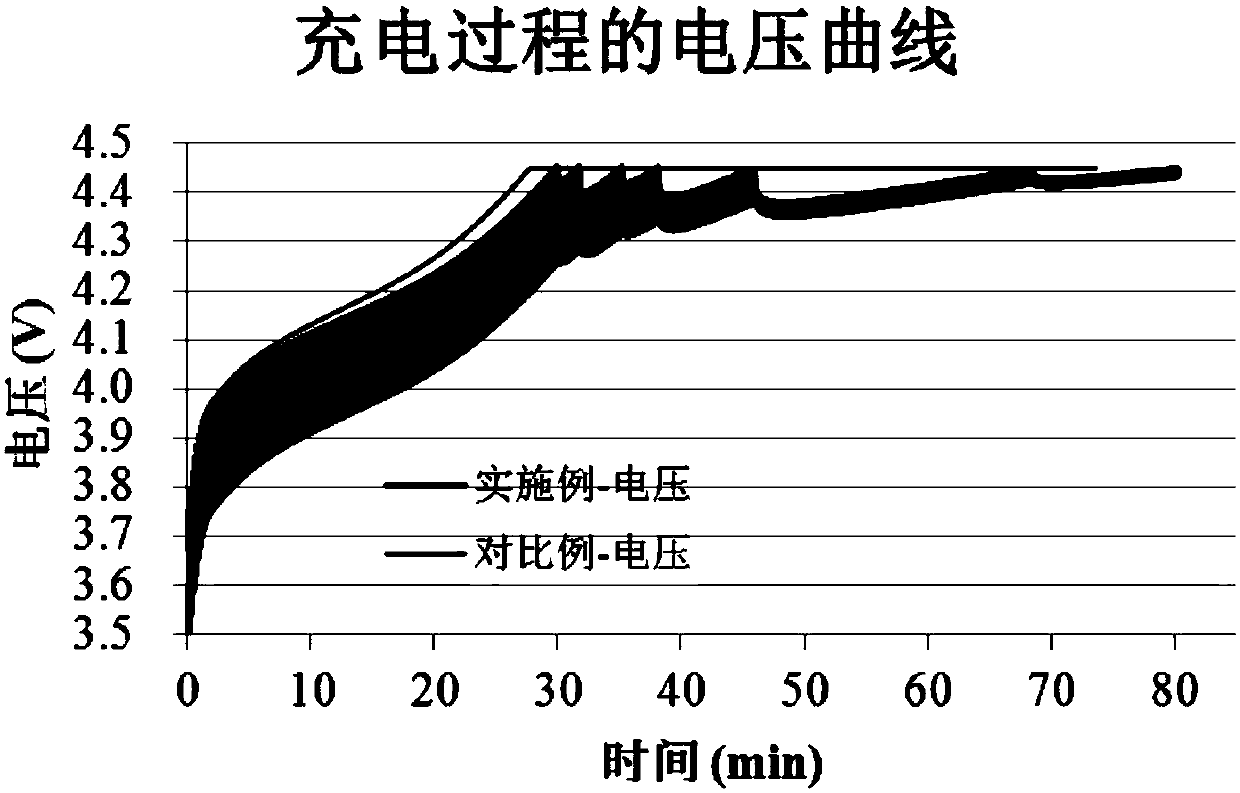

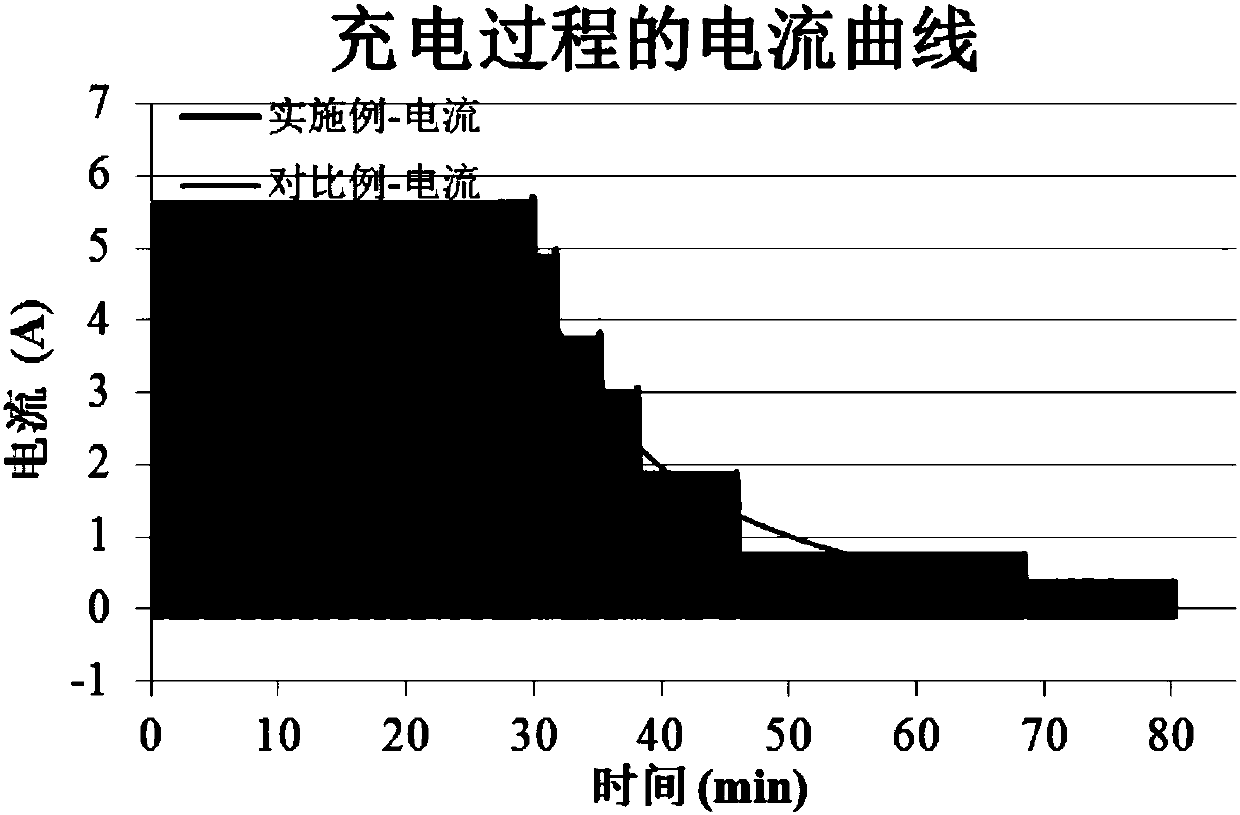

[0036] The concrete steps of embodiment 1 are as follows:

[0037] 1) Set a set of successively decreasing charging current values {1.5C, 1.3C, 1C, 0.8C, 0.5C, 0.2C, 0.1C}, and a set of discharging current values {0.02C, 0.015C, 0.01C, 0.01 C,0.01C,0.01C,0C}, a set of charging time values {9.5s, 9.5s, 9.5s, 9.5s, 9s, 9s, 8s}, and a set of discharging time values {0.5s, 0.5s, 0.5 s, 0.5s, 0.2s, 0.2s, 0.1s}; set the charging cut-off voltage to 4.45V; place the battery in an environment of 45°C to charge and discharge the battery;

[0038] 2) Charge with a current of 1.5C for 9.5s, then discharge with a current of 0.02C for 0.5s,

[0039] 3) Repeat step 2) until the battery voltage reaches 4.45V;

[0040] 4) Charge with a current of 1.3C for 9.5s, then discharge with a current of 0.015C for 0.5s,

[0041] 5) Repeat step 4) until the battery voltage reaches 4.45V;

[0042] 6) Charge with a current of 1C for 9.5s, then discharge with a current of 0.01C for 0.5s,

[004...

Embodiment 2

[0055]The concrete steps of embodiment 2 are as follows:

[0056] 1) Set a set of successively decreasing charging current values {5C, 1.5C, 1C, 0.5C, 0.2C}, a set of discharging current values {0.2C, 0.03C, 0.02C, 0.01C, 0.01C}, a A set of charging time values {1s, 30s, 5s, 5s, 2s}, and a set of discharging time values {0.01s, 5s, 0.5s, 0.5s, 0.1s}; set the charging cut-off voltage to 4.45V, and the charging cut-off current to 0.05C; place the battery in an environment of 45°C to charge and discharge the battery;

[0057] 2) Charge with a current of 5C for 1s, then discharge with a current of 0.2C for 0.01s,

[0058] 3) Repeat step 2) until the battery voltage reaches 4.45V;

[0059] 4) Charge with a current of 1.5C for 30s, then discharge with a current of 0.03C for 5s,

[0060] 5) Repeat step 4) until the battery voltage reaches 4.45V;

[0061] 6) Charge with a current of 1C for 5s, then discharge with a current of 0.02C for 0.5s,

[0062] 7) Repeat step 6) unt...

Embodiment 3

[0069] The concrete steps of embodiment 3 are as follows:

[0070] 1) Set a set of successively decreasing charging current values {1.5C, 1.4C, 1.3C, 1.2C, 1.1C, 1.0C, 0.9C, 0.8C, 0.7C, 0.6C, 0.5C, 0.4C, 0.3 C,0.2C,0.1C}, a set of discharge current values {0.05C,0.05C,0.05C,0.05C,0.05C,0.05C,0.05C,0.05C,0.05C,0.05C,0.05C,0.02C ,0.02C,0C,0.01C}, a set of charging time values {10s, 10s, 10s, 10s, 10s, 10s, 10s, 10s, 10s, 10s, 10s, 5s, 5s, 5s, 0.1s}, and a Group discharge time value {1s,1s,1s,1s,1s,1s,1s,1s,1s,1s,1s,1s,1s,1s,0.01s}. Set the charging cut-off voltage to 4.45V; place the battery in an environment of 45°C to charge and discharge the battery;

[0071] 2) Charge with a current of 1.5C for 10s, then discharge with a current of 0.05C for 1s,

[0072] 3) Repeat step 2) until the battery voltage reaches 4.45V;

[0073] 4) Charge with a current of 1.4C for 10s, then discharge with a current of 0.05C for 1s,

[0074] 5) Repeat step 4) until the battery voltage rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com