An anti-static mechanism for electrical explosives

A kind of electrical explosives, anti-static technology, applied in the protection of damage caused by electrostatic discharge, electrical components, magnetic field / electric field shielding and other directions, can solve the problems of small size, difficult parts processing, poor technical operation, etc Safety concerns, easy assembly control, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

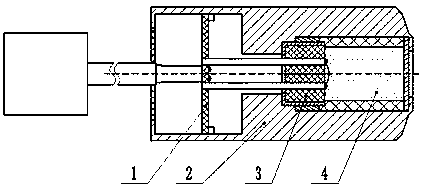

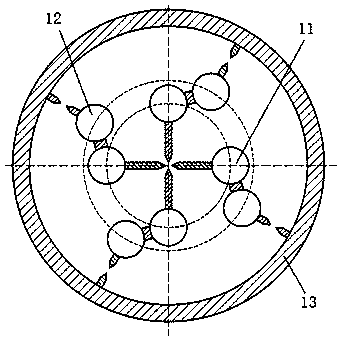

[0019] see figure 1 and figure 2 , an anti-static mechanism for electrical pyrotechnics, including a PCB board 1, a housing 2, an electrode plug 3 and an ignition powder 4, wherein the PCB board 1, the electrode plug 3 and the ignition powder 4 are all located in the housing 1 Inside, and the PCB board 1, the electrode plug 3 and the ignition powder 4 are sequentially arranged in the housing 1, and the PCB board 1 is sealed in the housing 2; the PCB board 1 includes sequentially from the inside to the outside Four inner circles 11, four outer circles 12 and an outer metal layer 13, the inner circles 11 are connected to the foot wires of the electrode plug 3 by welding, the outer circles 12 are connected to the external wires The outer ring metal layer 13 is connected to the casing 2 by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com