Positioning and drilling mechanism of vibrating disk spring piece production device

A drilling mechanism and production device technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of complex process and low efficiency, so as to improve production efficiency and reduce time waste , the effect of saving replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

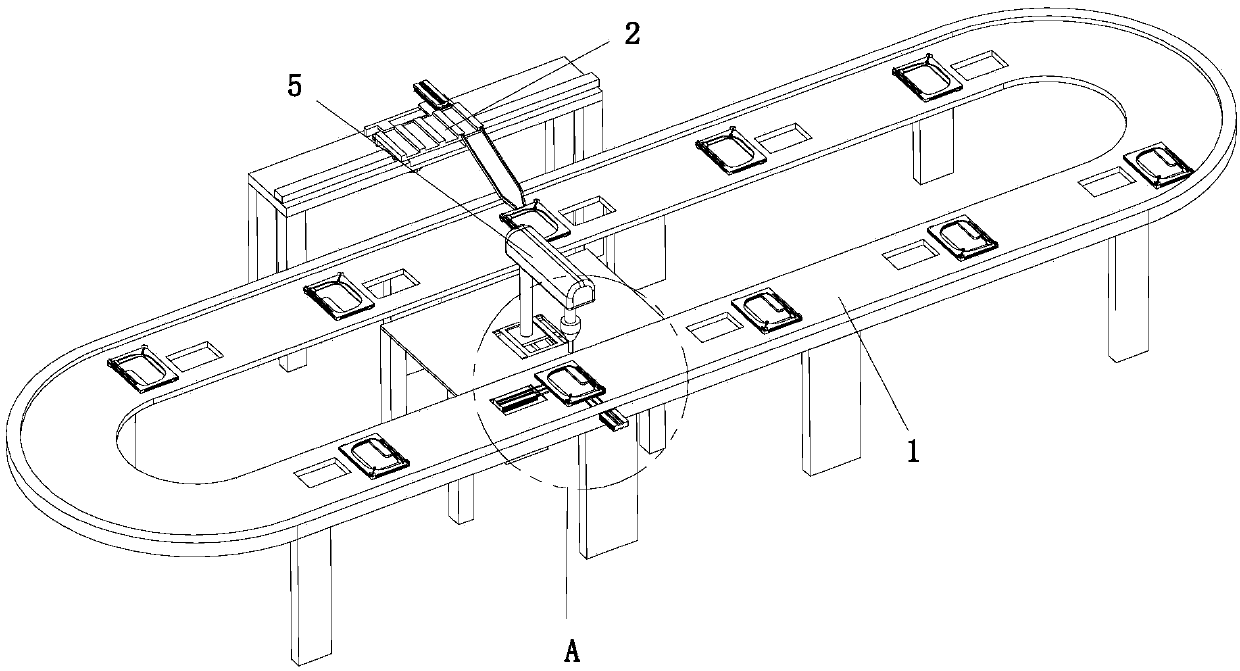

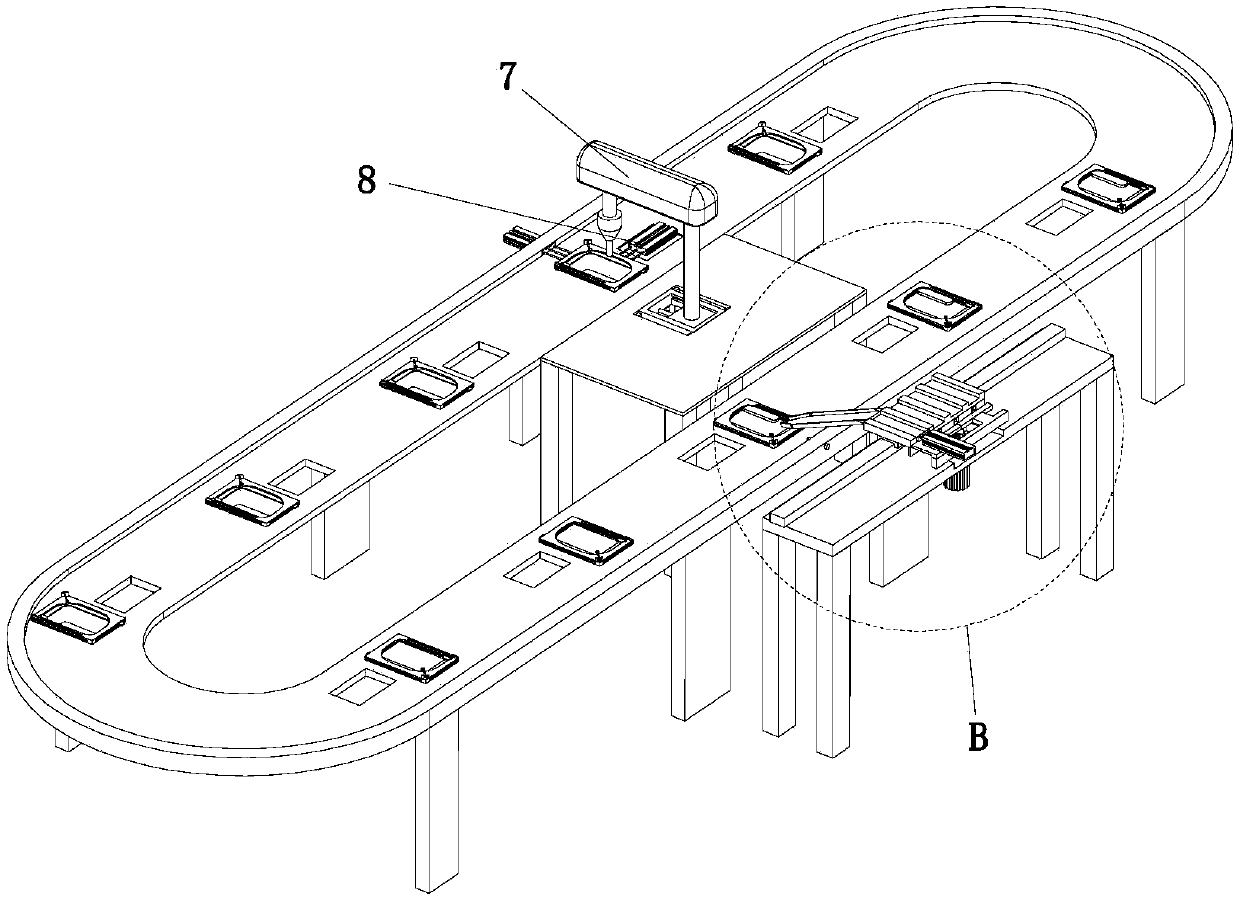

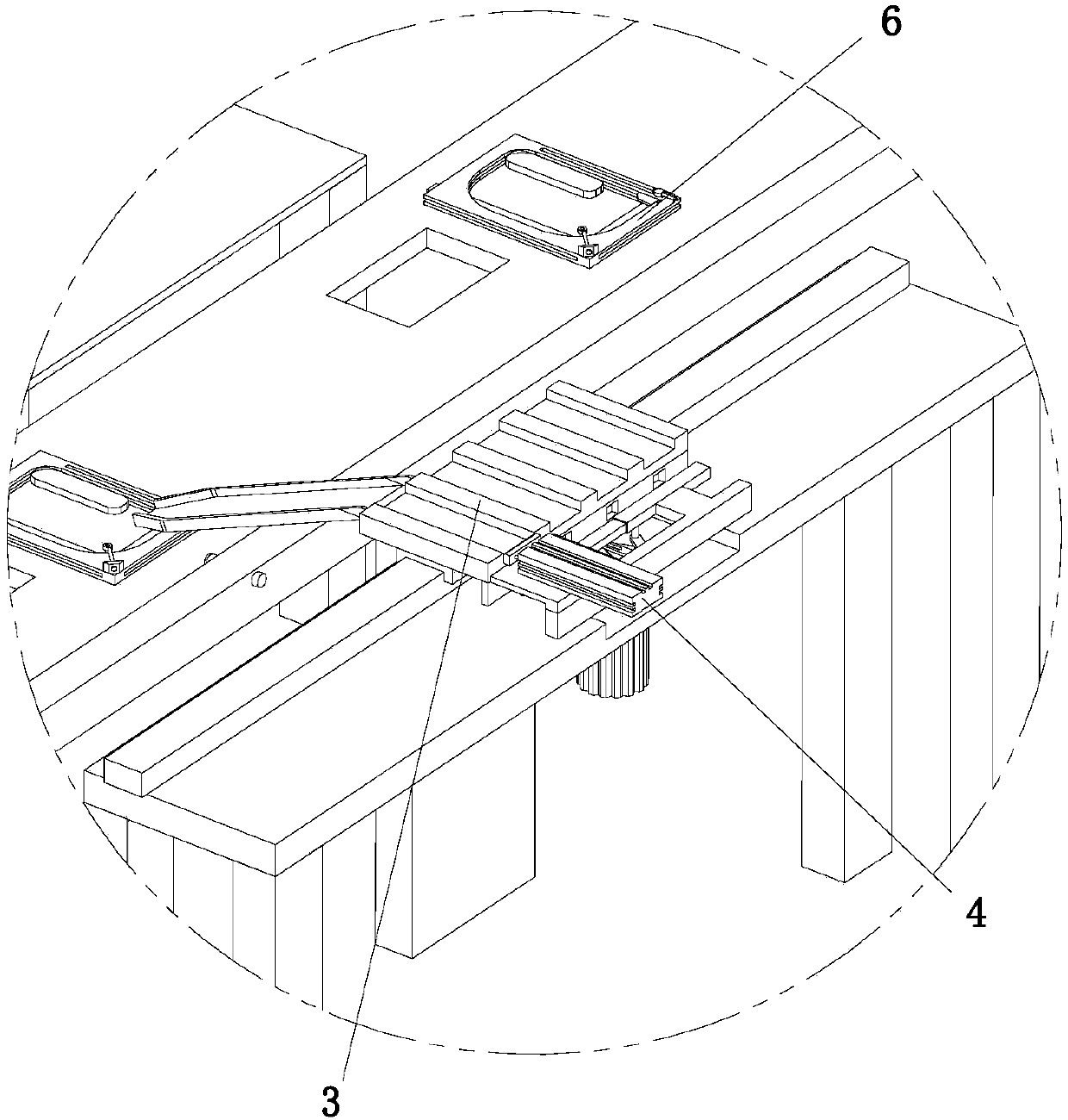

[0031] refer to Figure 1 to Figure 14 The shown a kind of vibrating disk spring sheet production device comprises endless conveyor belt 1, feeding device 2 and positioning drilling mechanism 5, and described endless conveyor belt 1 is provided with feeding station and drilling station, and feeding device 2 It is arranged on the side of the feeding station of the endless conveyor belt 1, and the positioning drilling mechanism 5 is arranged on the side of the drilling station of the endless conveyor belt 1. The positioning jig 6, the driving mechanism 8 for driving the positioning jig 6 to clamp the spring leaf and the drilling mechanism 7 for drilling the spring leaf, the feeding device 2 includes a feeding mechanism for stacking the spring leaf 3 and the pushing mechanism 4 used in the positioning jig 6 that is used to deliver the leaf spring to the endless conveyor belt 1.

[0032] Working principle: put the spring piece in the placement groove 3a1 on the stacking tray 3a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com