Telescopic numerical control cutter frame

A tool rack and connecting plate technology, which is applied in the direction of manufacturing tools, tool storage devices, metal processing machinery parts, etc., can solve the problems of low space utilization, limited capacity of placing plates, inconvenient use, etc., and achieve easy to take and store, Ease of use and increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

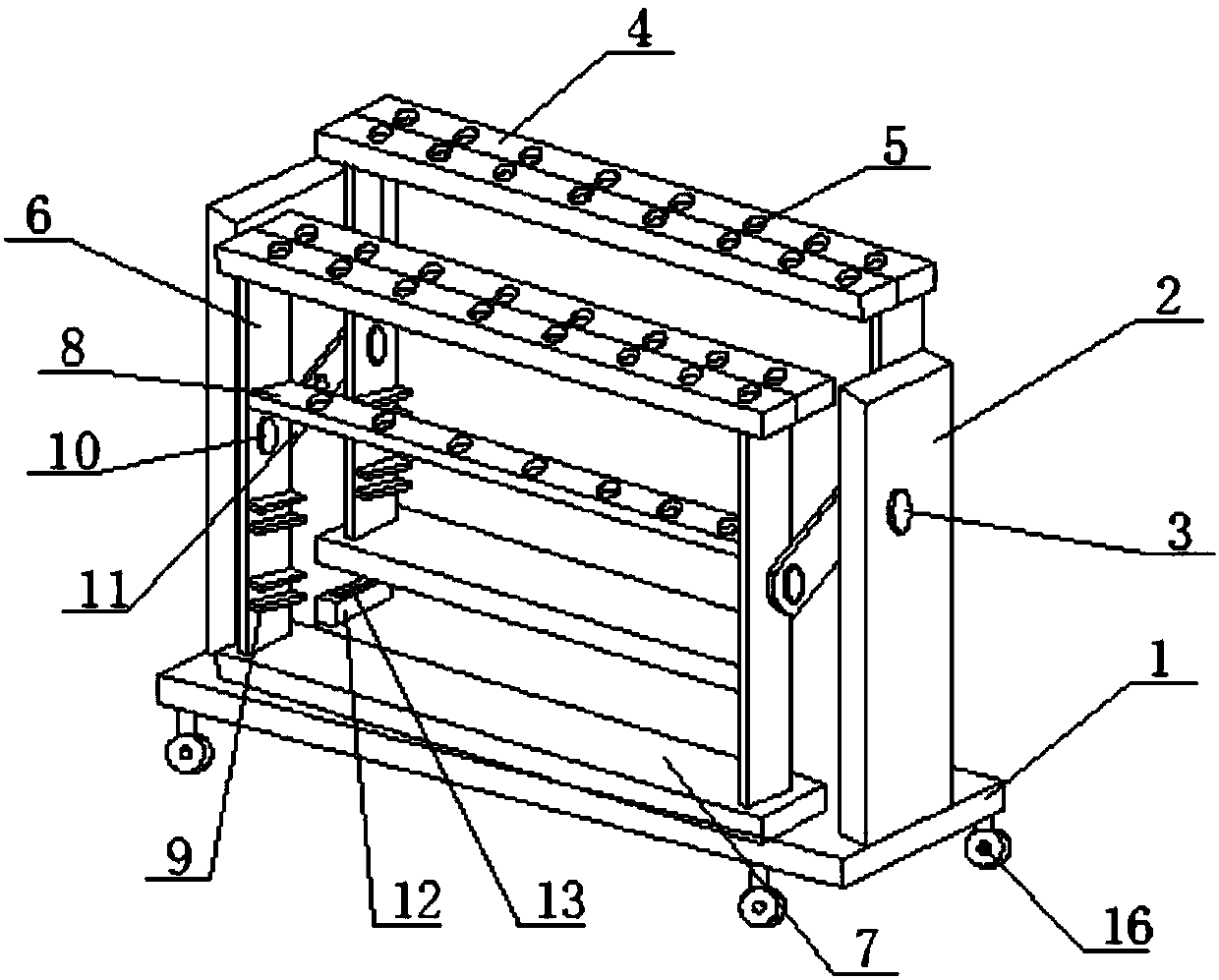

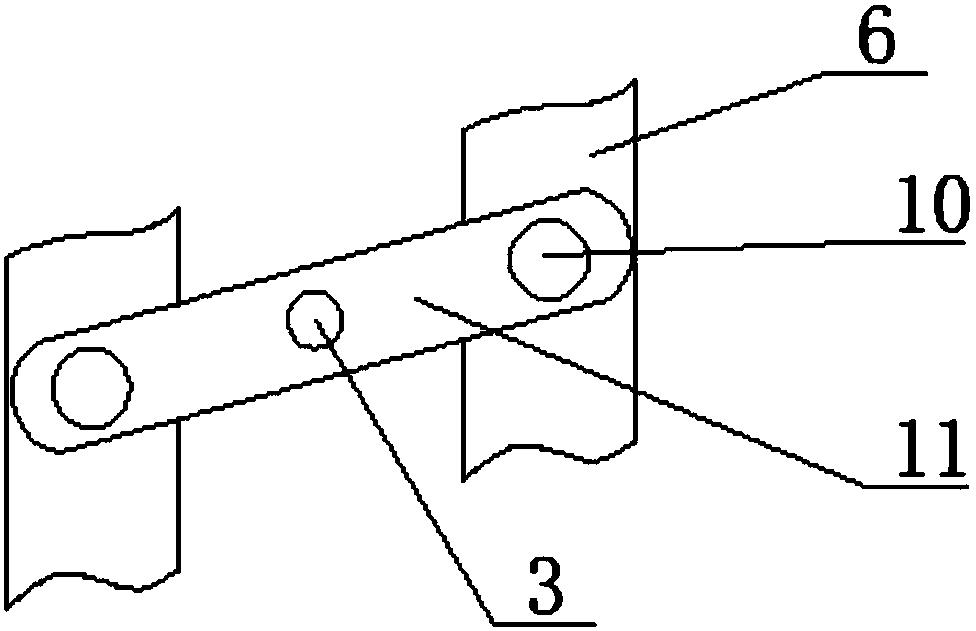

[0022] see figure 1 and figure 2 As shown, a telescopic CNC tool holder includes a base 1, a placement beam 4 and a placement hole 5, the base 1 is connected to a support plate 2 for supporting the device, and a center pin 3 is set at the center of the support plate 2 for easy balance Placement beams 4 on both sides, placement holes 5 are set on the placement beams 4 for placing tools, placement beams 4 are connected to the connection plate 6, connection plate 6 is connected to the bottom plate 7, and the upper end of the connection plate 6 is connected to the beam 8, and more Strengthen the fixation of the tool at the same time, increase the overall stability of the device, a splint 9 is provided at the bottom of the connecting plate 6, and is used to place a movable connecting plate to increase the space for accommodating the tool, and a movable pin 10 is set in the middle of the connecting plate 6, The movable pin 10 is connected with the balance beam 11, which is used to...

Embodiment 2

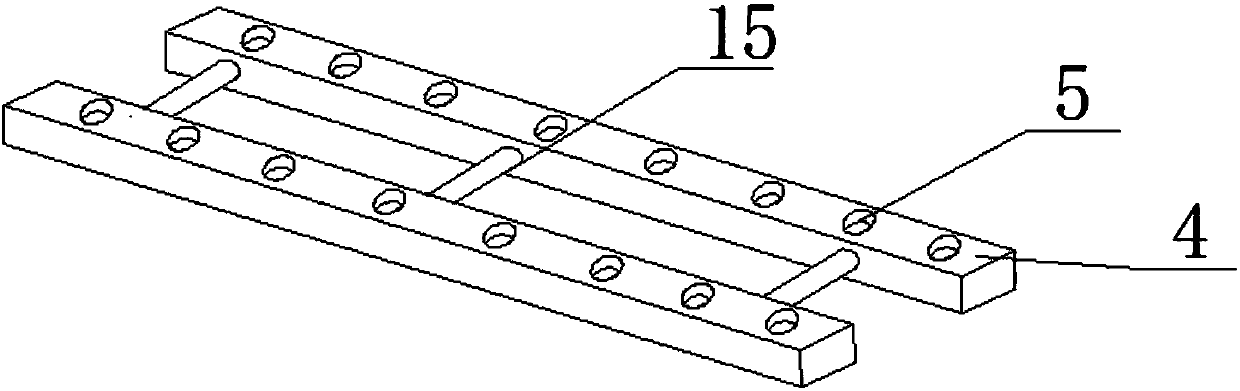

[0024] In addition, refer to figure 2 , image 3 and Figure 4 , based on the above-mentioned embodiment, a symmetrical support plate 2 is arranged on the base 1, and the support plate 2 is vertically and parallelly arranged so that the device can be supported stably. The center pin 3 is arranged at the center of the support plate 2 on both sides. 3 Corresponding settings, so that the force on both sides is balanced, and it is convenient for the placement beams 4 on both sides to move up and down. The placement beams 4 are movable settings, and the placement beams 4 on both sides can be separated freely. 5. Make the placement beam 4 able to place a more correct tool and facilitate the taking of the tool. A single row of placement holes 5 is set on the cross beam 8. The placement holes 5 are uniformly arranged. The cross beam 8 and the connecting plate 6 are fixedly connected, so that the cross beam 8 is connected It is firmer, and the connection between the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com