Energy consumption sleeve of prestress assembling node and mounting and working method thereof

A prefabricated and prestressed technology, applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve problems such as unfavorable repairs, complicated construction, weakened node strength and deformation ability, etc., and achieves convenient and rapid installation and replacement , Improve the strength and deformation ability, and the effect of superior energy dissipation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

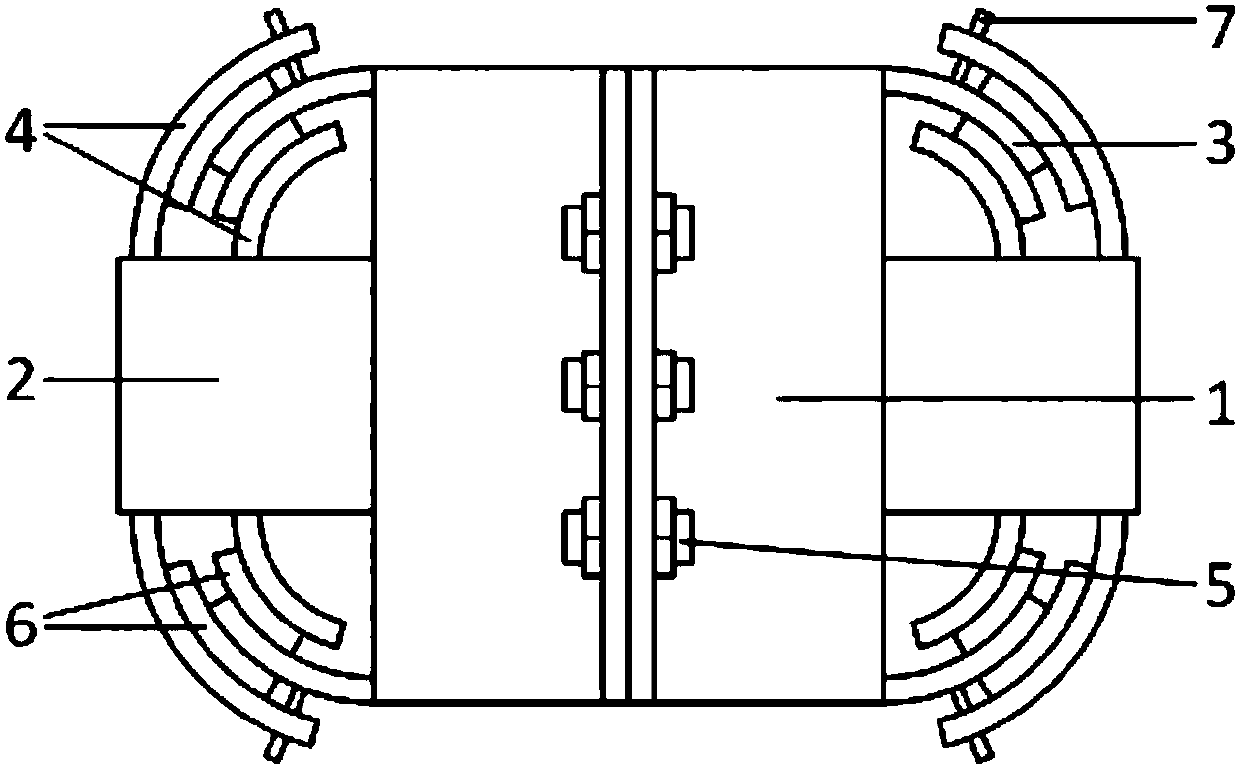

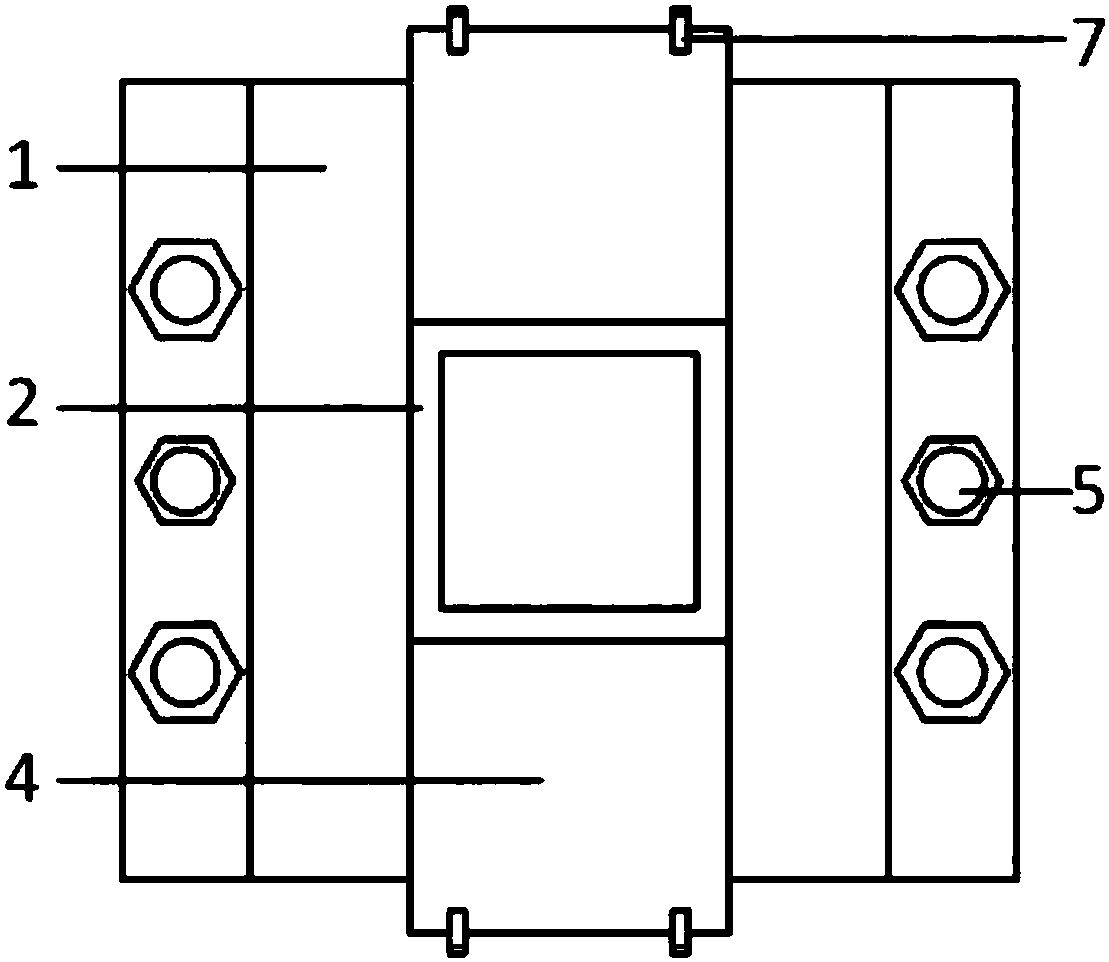

[0039] Such as Figure 1~4 As shown, the energy-dissipating sleeve of the prestressed assembled node of the present invention includes two left and right half-sleeves connected by high-strength bolts 5, and the two half-sleeves are symmetrical about the splicing plane. Each half-sleeve includes a vertical column sleeve 1 and a horizontal beam end sleeve 2. The column sleeve 1 and the beam end sleeve 2 are connected through and only through the arc-shaped viscoelastic dampers at the corners. The column sleeve 1 and the beam end sleeve 2 are only in contact with each other in the vertical contact plane, and there is no connection, which ensures that the beam-column components connected by prestressed tendons can rotate freely.

[0040] The column sleeve 1 has a hole on the vertical contact plane with the beam end sleeve 2, and the size of the hole is consistent with the inner edge of the beam end sleeve 2, which ensures that the beam-column joints can be directly contacted and t...

Embodiment 2

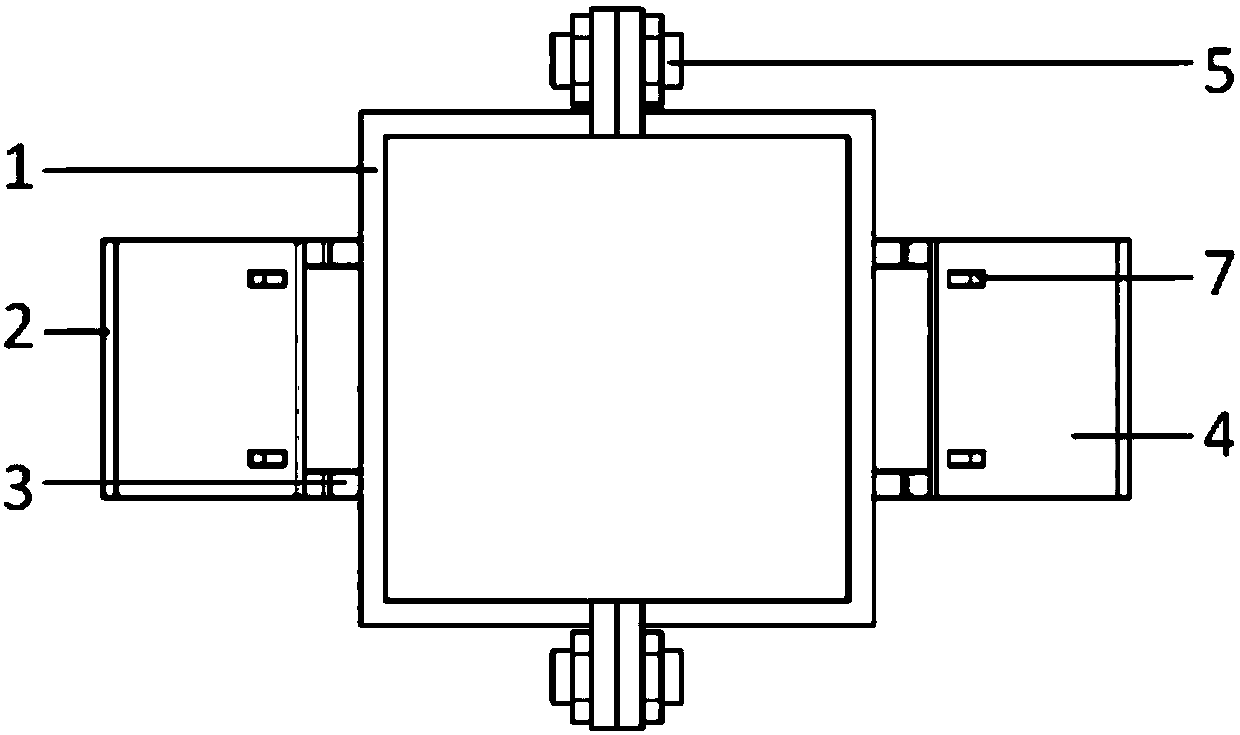

[0048] Such as Figure 6~8 As shown, the energy-dissipating sleeve of the prestressed assembled node in this embodiment includes four sub-sleeves connected by high-strength bolts 5, the four sub-sleeves are exactly the same, and are set on the four prefabricated beam members around the column. The end plates 8 are welded at the joints, and the high-strength bolts of the end plates 8 are combined to form an integral sleeve covering the beam-column joints. Each sub-sleeve includes a vertical column sleeve 1 and a horizontal beam end sleeve 2. The column sleeve 1 and the beam end sleeve 2 are connected through and only through the arc-shaped viscoelastic damper at the corner. The column sleeve 1 and the beam end sleeve 2 are only in contact with each other in the vertical contact plane, and there is no connection, which ensures that the beam-column components connected by prestressed tendons can rotate freely.

[0049] The column sleeve 1 has a hole on the vertical contact plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com