Auxiliary frame bush assembly

A subframe and bushing technology, applied to springs, springs/shock absorbers, and mechanical equipment made of plastic materials, can solve problems such as stress concentration, easy wear, and affecting bushing fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

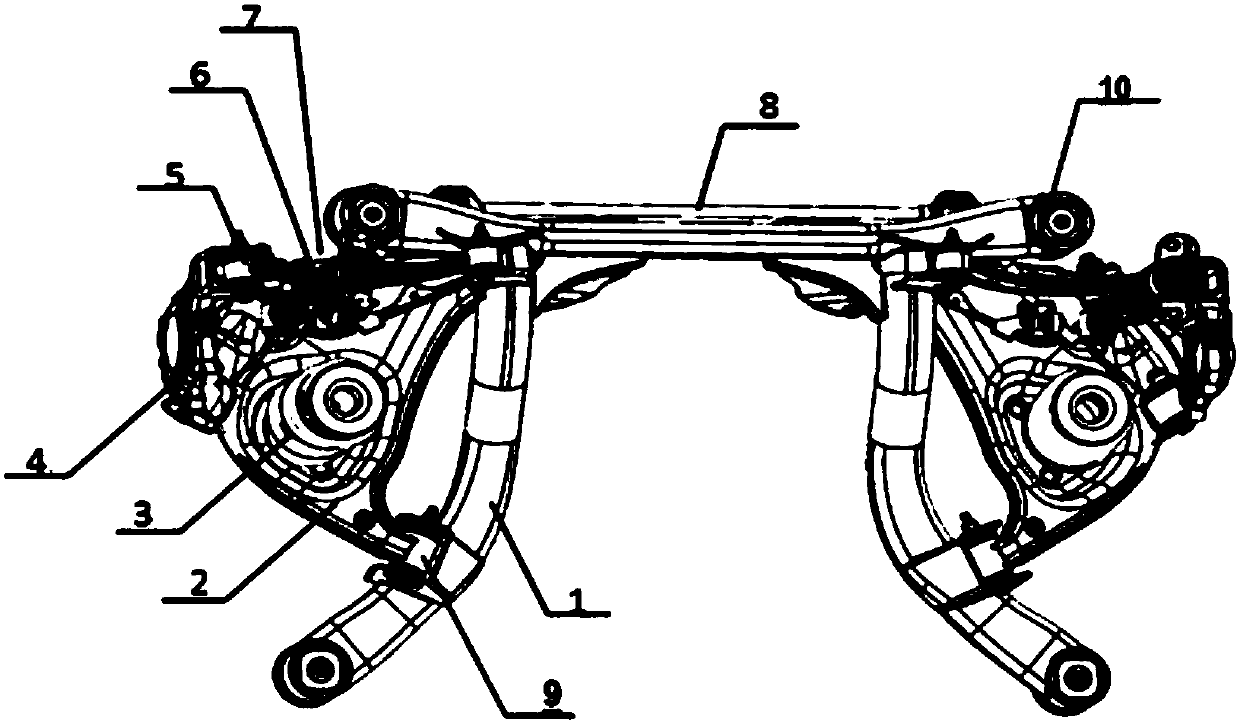

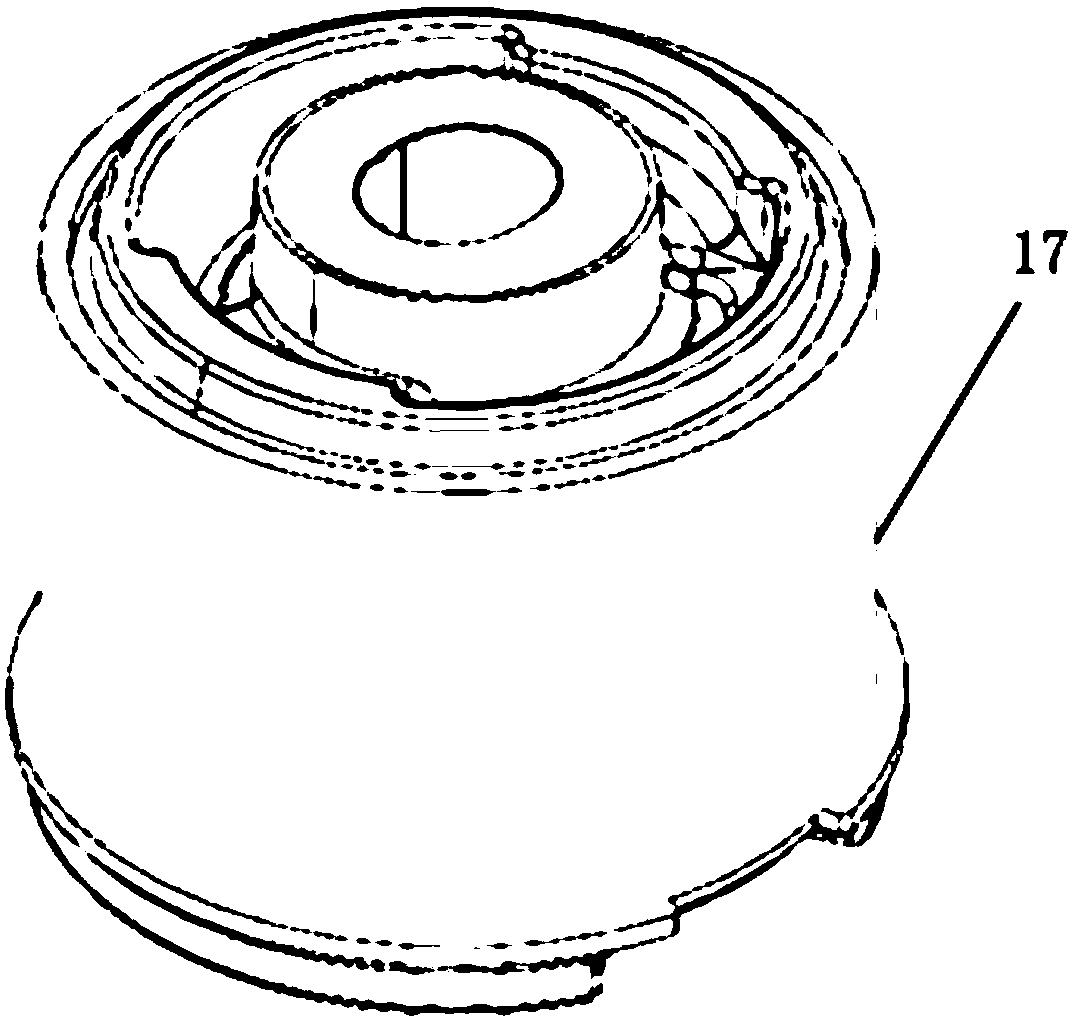

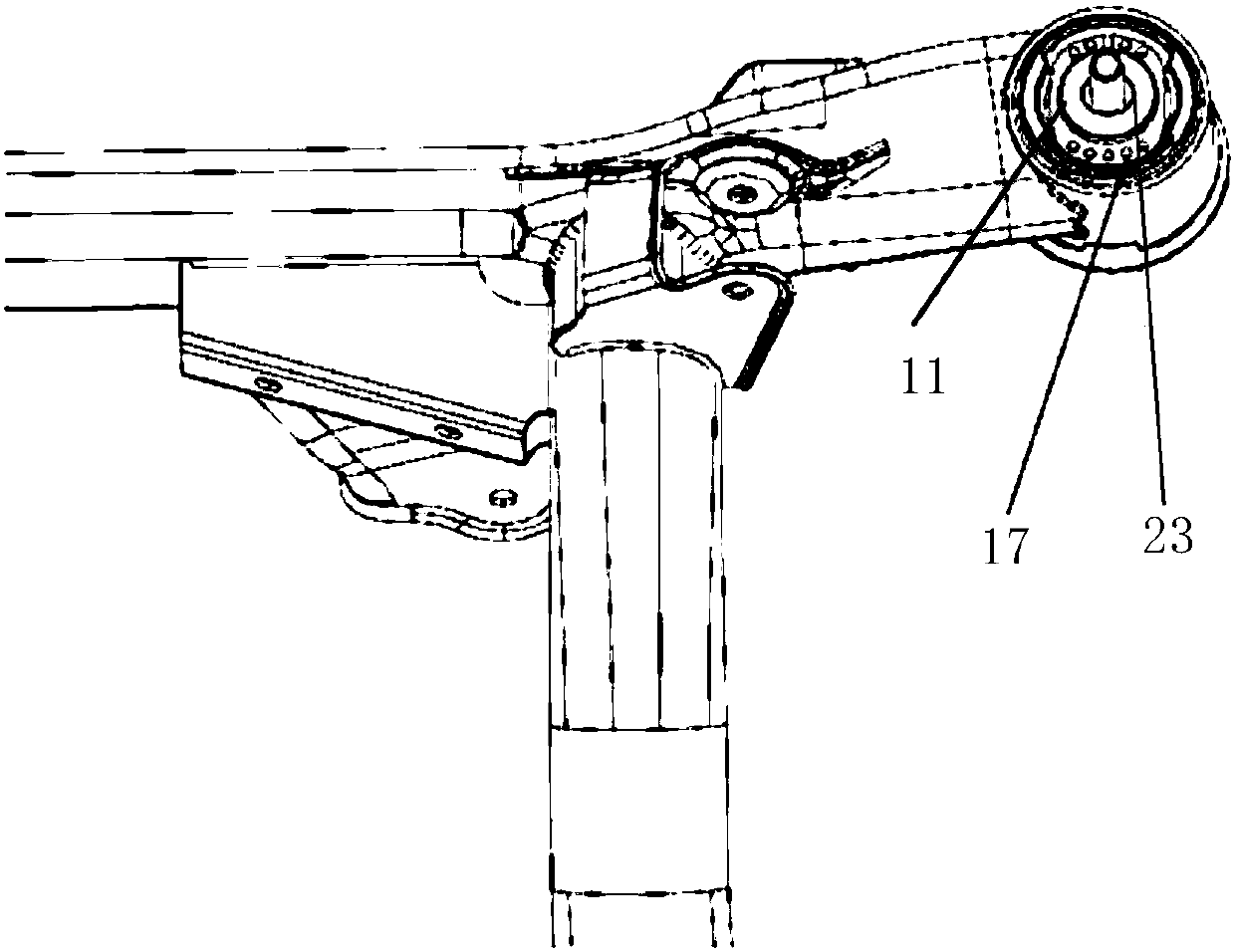

[0034] The following with attached Figure 3 to Figure 7 A subframe bushing assembly of the present invention is further described in detail.

[0035] A subframe bushing assembly of the present invention, please refer to Figure 3-7 , comprising an inner lining pipe 11, an outer lining pipe 12, a main rubber spring 13, an upper pressing block 14 and a lower pressing block 15, the inner lining pipe 11 is arranged in the main rubber spring 13, and the outer wall of the inner lining pipe 11 Against the inner wall of the main rubber spring 13, the outer liner 12 is fixed on the outer periphery of the main rubber spring 13, the inner wall of the outer liner 12 is opposed to the outer wall of the main rubber spring 13, and the upper pressing block 14 And the lower pressure block 15 is detachably fixed on the upper and lower ends of the rubber main spring 13 . In this way, when the car is running, due to the complex and changeable driving conditions of the vehicle, the sub-frame bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com