A mems direct pull direct compression type two-axis accelerometer chip and preparation method thereof

A technology of axial acceleration and direct pull and direct compression, which is applied in the direction of acceleration measurement using inertial force, can solve the problems affecting the improvement of acceleration sensors, achieve the effect of improving sensitivity and resonance frequency, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

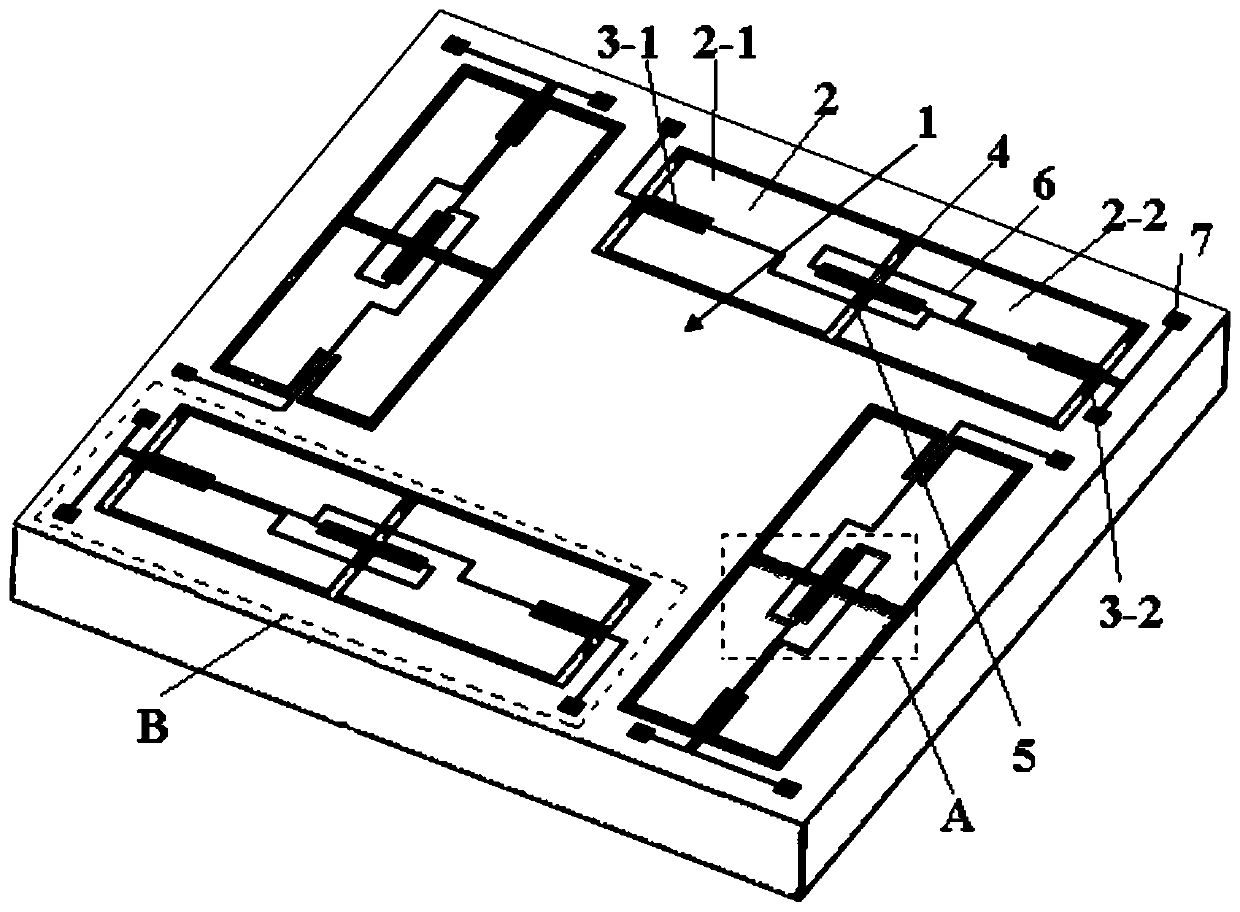

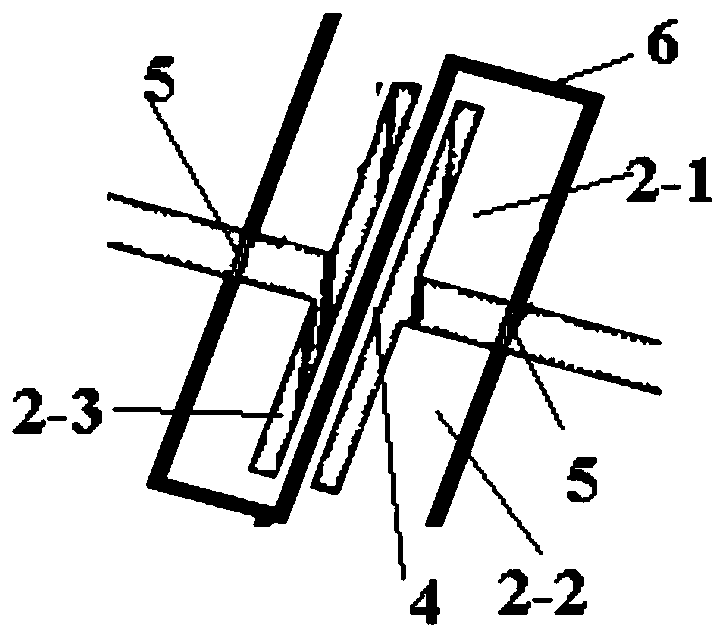

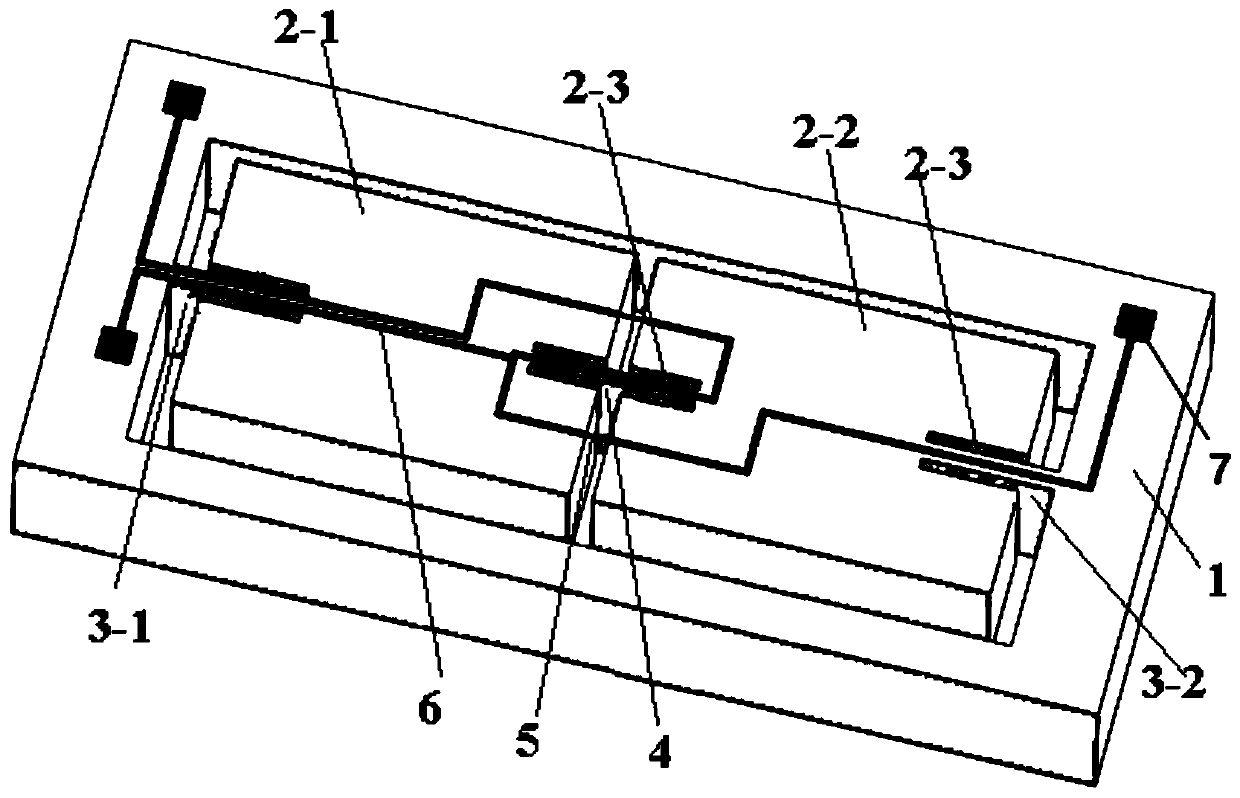

[0074] As a preferred embodiment of the present invention, the accelerometer chip of the present embodiment is made of SOI (Silicon on Insulator) silicon wafer: the whole structure is formed by four identical sensor subunits rotating around the center of the accelerometer chip, two in the same direction A group of sensor units measures the in-plane acceleration perpendicular to the direction. The chip frame 1 is fixed on the underlying glass plate 18 through a bonding process. The distance between the first and second mass blocks is the length of the sensitive beam 5; two sensitive beams 5 are arranged symmetrically on both sides of the hinge beam 4, and their two ends are respectively fixed on the first and second mass end of the block.

[0075] The process for preparing the in-plane MEMS piezoresistive two-axis accelerometer chip of this embodiment includes the following steps, combining Figure 6 :

[0076] Step 1, use the N-type (100) crystal surface to polish the SOI s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com