Semiconductor light-emitting element

A light-emitting element and semiconductor technology, which is applied in the direction of semiconductor devices, electrical components, electric solid-state devices, etc., can solve problems such as the reduction of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

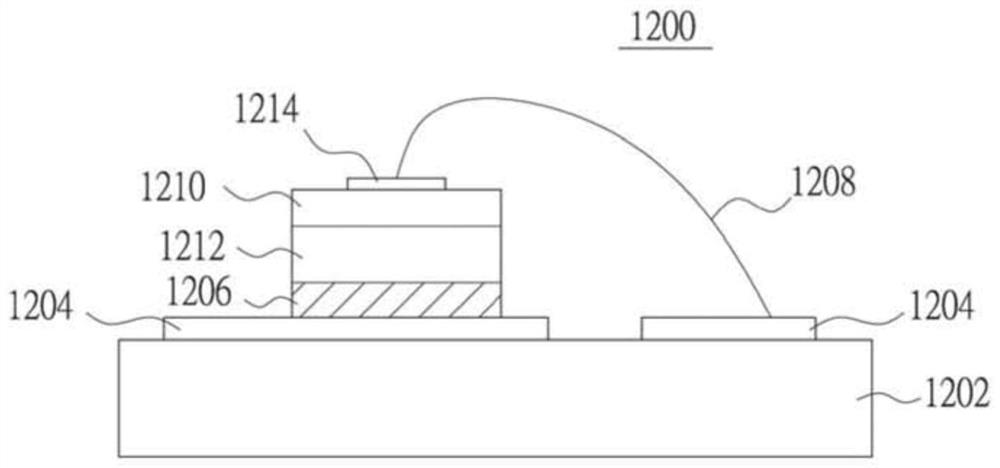

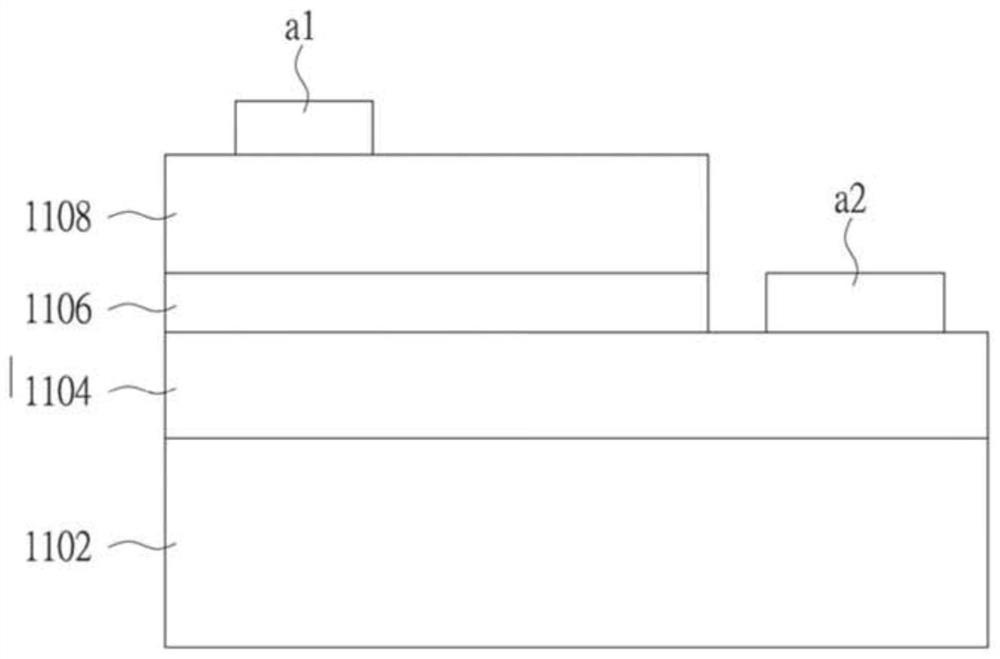

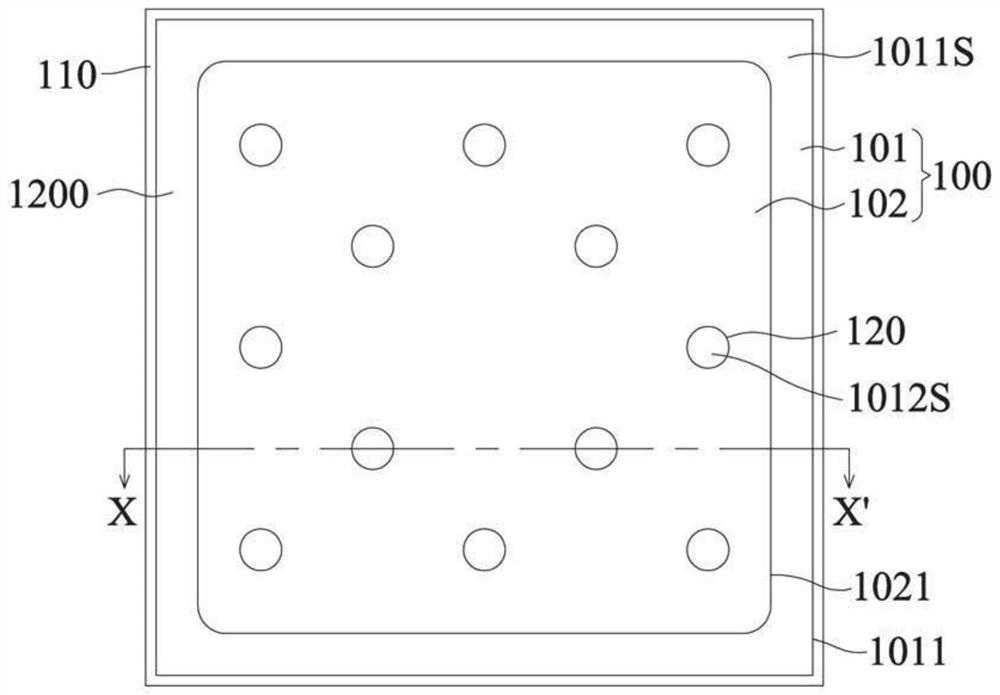

[0071] Figure 3A ~ Figure 10B It is a manufacturing method of the semiconductor light emitting element V according to an embodiment of the present invention. Figure 3A , Figure 4A , Figure 5A , Figure 6A , Figure 7A , Figure 8A , Figure 9A and Figure 10A for the floor plan. Figure 3B , Figure 4B , Figure 5B , Figure 6B , Figure 7B , Figure 8B , Figure 9B , Figure 10B respectively Figure 3A , Figure 4A , Figure 5A , Figure 6A , Figure 7A , Figure 8A , Figure 9A and Figure 10A Sectional view along X-X'.

[0072] Such as Figure 3A and Figure 3B As shown, a semiconductor stack 100 is formed on a growth substrate 110 . The growth substrate 110 may be a sapphire substrate, but is not limited thereto. The semiconductor stack 100 includes a first semiconductor layer 101 , a second semiconductor layer 102 , and an active layer 103 formed between the first semiconductor layer 101 and the second semiconductor layer 102 . Each of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com