Packaging structure, packaging method and photoelectric equipment

A packaging structure and packaging method technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as poor water vapor sealing effect, and achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

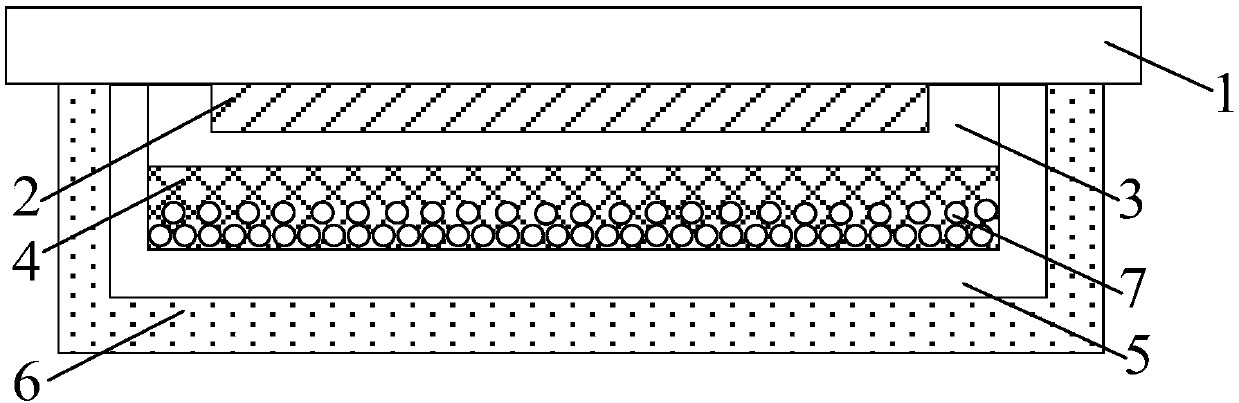

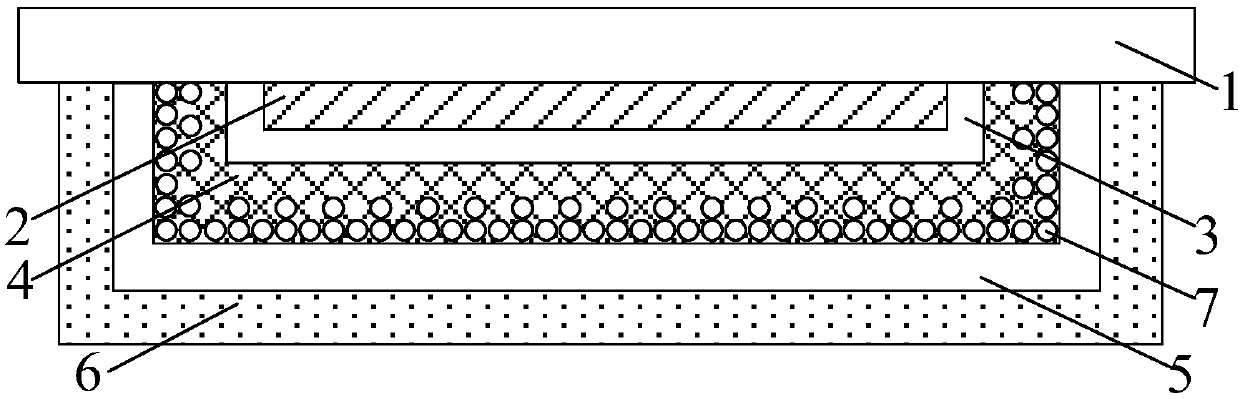

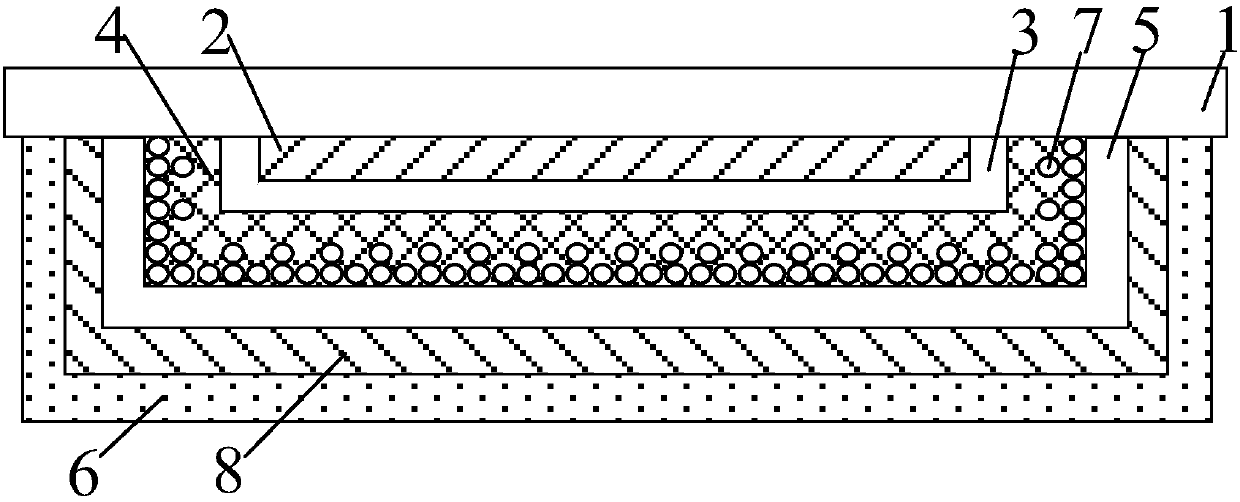

Method used

Image

Examples

preparation example Construction

[0082] The preparation temperature of the above-mentioned second water-absorbing layer varies according to different preparation methods. For example, when the chemical vapor deposition method is used, the temperature is generally above 130° C., and the vacuum evaporation method is generally used. The manufacturing temperature is between 25 and 40° C., while The production temperature of atomic layer deposition is generally between 60 and 100 ° C. Among them, the preparation temperature of vacuum evaporation method and atomic layer deposition method is within the tolerance temperature range of light-emitting devices, and will not have high temperature effects on light-emitting devices. Chemical vapor phase Even if the temperature of the second water-absorbing layer prepared by the deposition method exceeds the tolerance temperature range of the light-emitting device, its heat will be blocked by the reticular void layer and will not affect the light-emitting device. The function ...

Embodiment 1

[0090]The specific packaging process is in a class 100 clean room. The specific packaging methods include:

[0091] First, prepare an ITO (indium tin oxide) flexible substrate, and prepare a light-emitting device on the ITO flexible substrate. The light-emitting device includes a hole injection layer prepared on the surface of the ITO (the material is poly(3,4-ethylenedioxythiophene)- Polystyrene sulfonic acid, PEDOT:PSS), prepare hole transport layer (material is polyvinyl carbazole PVK) on hole injection layer upper surface, the quantum dot light-emitting layer on hole transport layer surface (material is CdSe / ZnS core-shell quantum dots), and an electron transport layer (ZnO nanoparticles) on the surface of the quantum dot light-emitting layer, and a cathode (material is Ag) on the electron transport layer.

[0092] Then, coat a layer of copper oxide nanoparticle ink on the cathode surface of the light-emitting device and other surfaces of the light-emitting device that...

Embodiment 2

[0098] The specific packaging process is in a class 100 clean room. The specific packaging methods include:

[0099] First, an ITO flexible substrate is prepared, and a light-emitting device is fabricated on the ITO flexible substrate, and this step is the same as that of the above-mentioned embodiment 1.

[0100] Then, forming a pre-resistance liquid layer, this step is the same as the above-mentioned embodiment 1;

[0101] Coat a layer of ketone airgel solution on the pre-resistance liquid layer, its solvent mainly includes methyl ethyl ketone, use coating and printing equipment to make ketone airgel, and then use low critical drying process to process it , dry at a drying temperature of 85°C and a critical pressure of 3Mpa for 5 minutes to prepare the pre-void layer, and sinter the upper pre-void layer and the pre-resistance layer together with a xenon lamp to form a reticular void layer and a liquid-resistance layer. The thickness of each layer is 2 μm and 30 nm, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com