Bread making device

A technology for making a device and bread, which is applied to dough mixers, kitchen utensils, household utensils, etc., can solve the problems of large error in addition amount and large difference in the size of bread, and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

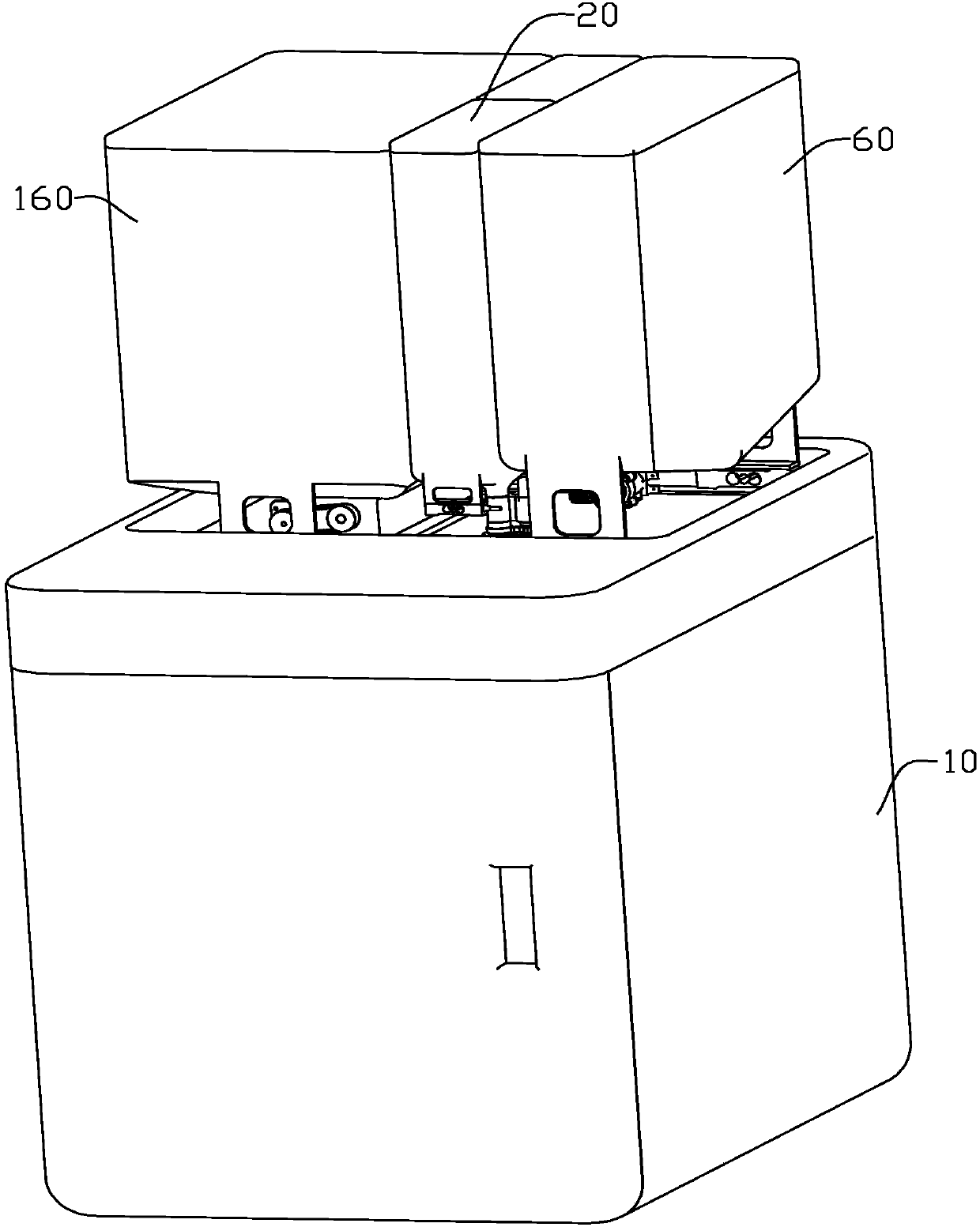

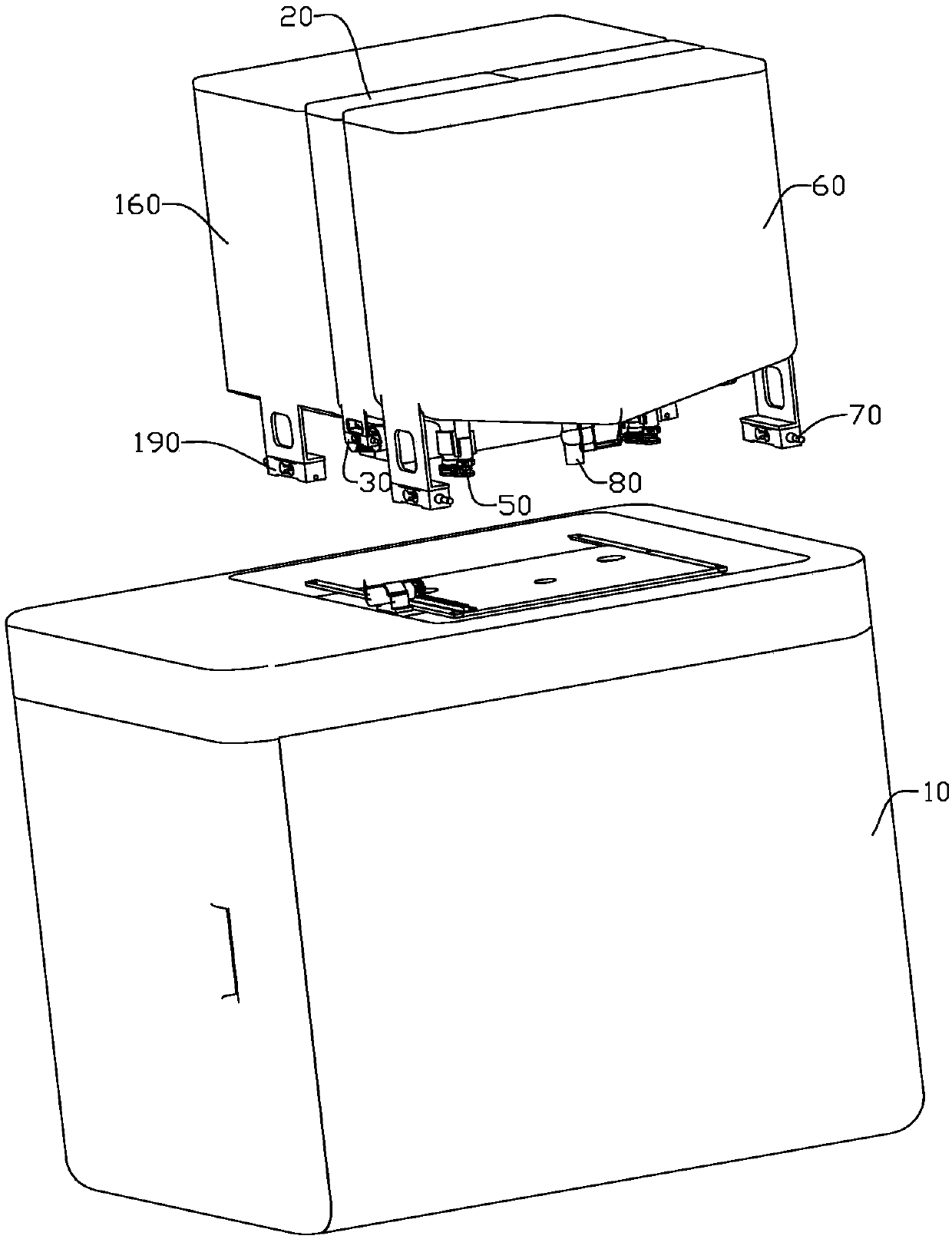

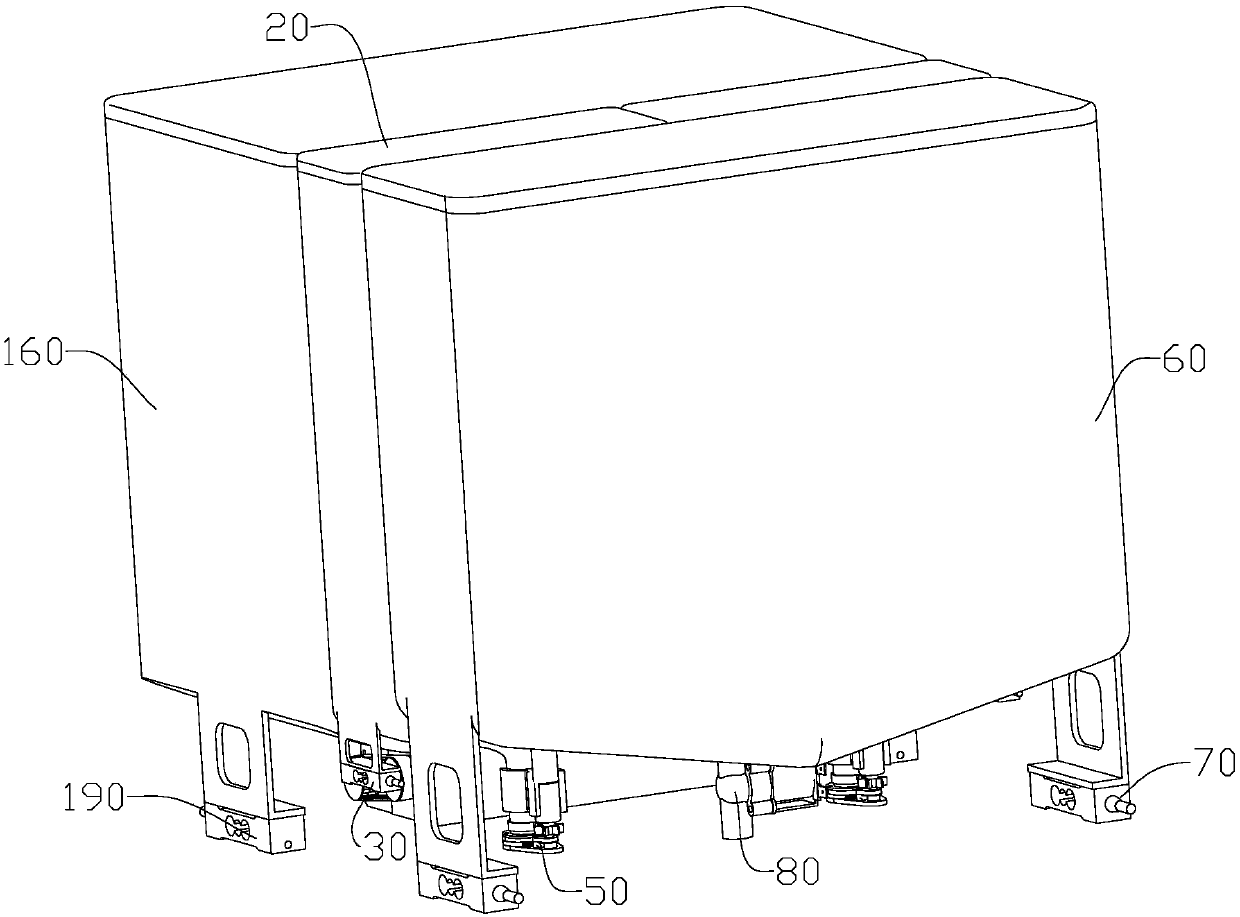

[0030] Such as Figure 1-3 The shown bread making device comprises a bread machine 10, a first bucket 20 and a first load cell 30; the bread machine 10 is used to make bread; The opening is provided with a first opening and closing mechanism 40 for controlling its opening or closing; the first bucket 20 is provided with a first discharge opening towards the first feed opening, so that the raw materials discharged from the first discharge opening can be Directly enter the bread machine 10 through the first feed port; the first discharge port is provided with a second opening and closing mechanism 50 for controlling its opening or closing; the detection...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap