Grinding and pulping device for river snail rice noodle raw materials

A technology for snail noodles and rice noodles, which is applied to mixers with rotary stirring devices, application, transportation and packaging, etc., can solve problems such as low work efficiency, bacterial growth, complex structure, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

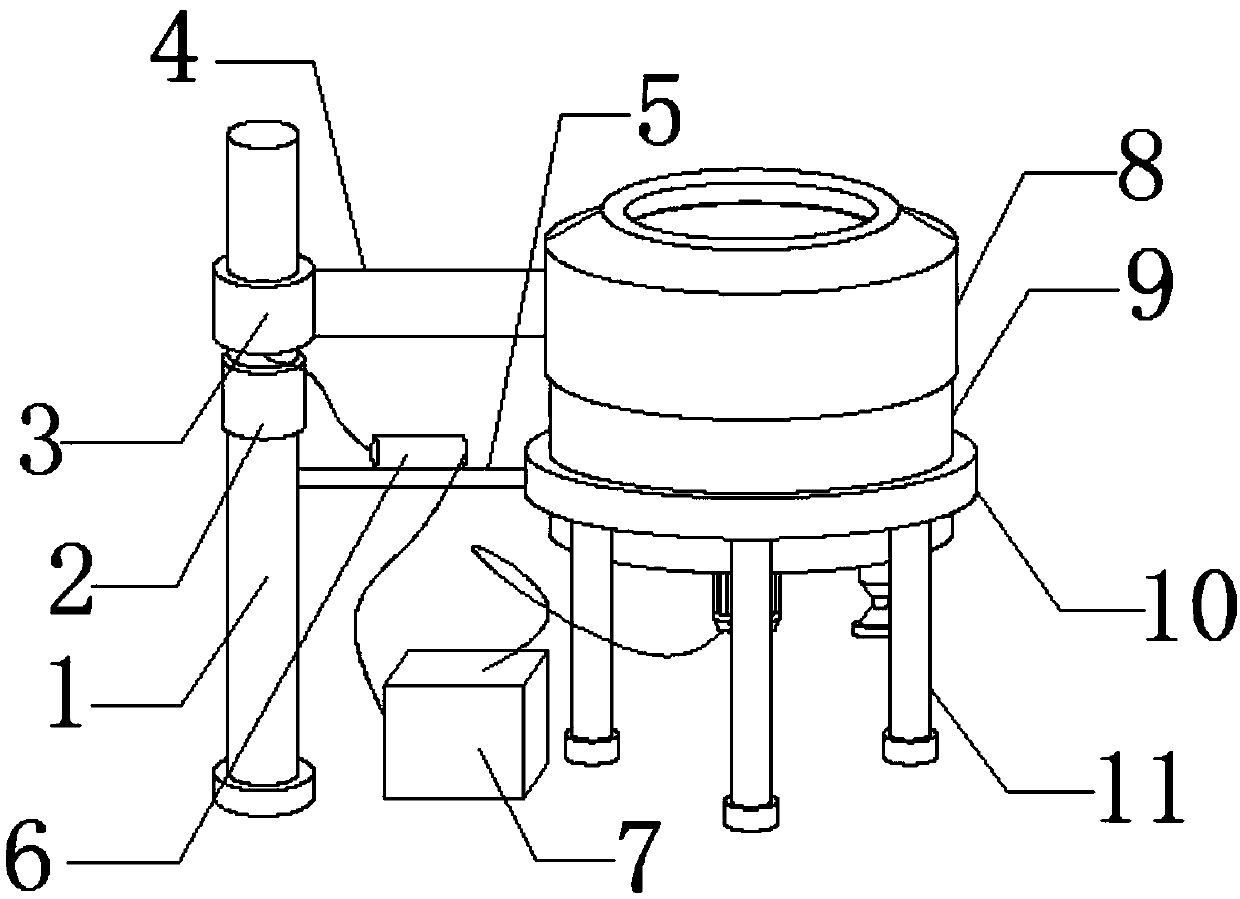

[0025] see Figure 1-5 Shown, a kind of milling beating device that is used for snail powder rice noodle raw material, comprises vertical rod 1, power supply box 7, upper grinding disc 14 and lower grinding column 15, telescopic rod 2 is installed on the top of vertical rod 1, through vertical rod 1 and support The legs 11 work together as the main support of the device; the top end of the telescopic rod 3 is set with the connecting bolt 3, and the connecting rod 4 is arranged on one side of the connecting bolt 3, and the upper grinding disc 8 and the telescopic rod 2 are connected through the connecting bolt 3 and the connecting rod 4, which is convenient for both The separation of the connecting rod 4; the auxiliary rod 5 is set under the connecting rod 4, and the lateral support of the device is given through the auxiliary rod 5, so that the work of the device is more stable; the hydraulic pump 6 is installed on the auxiliary rod 5, and the telescopic rod 2 is given the tele...

Embodiment 2

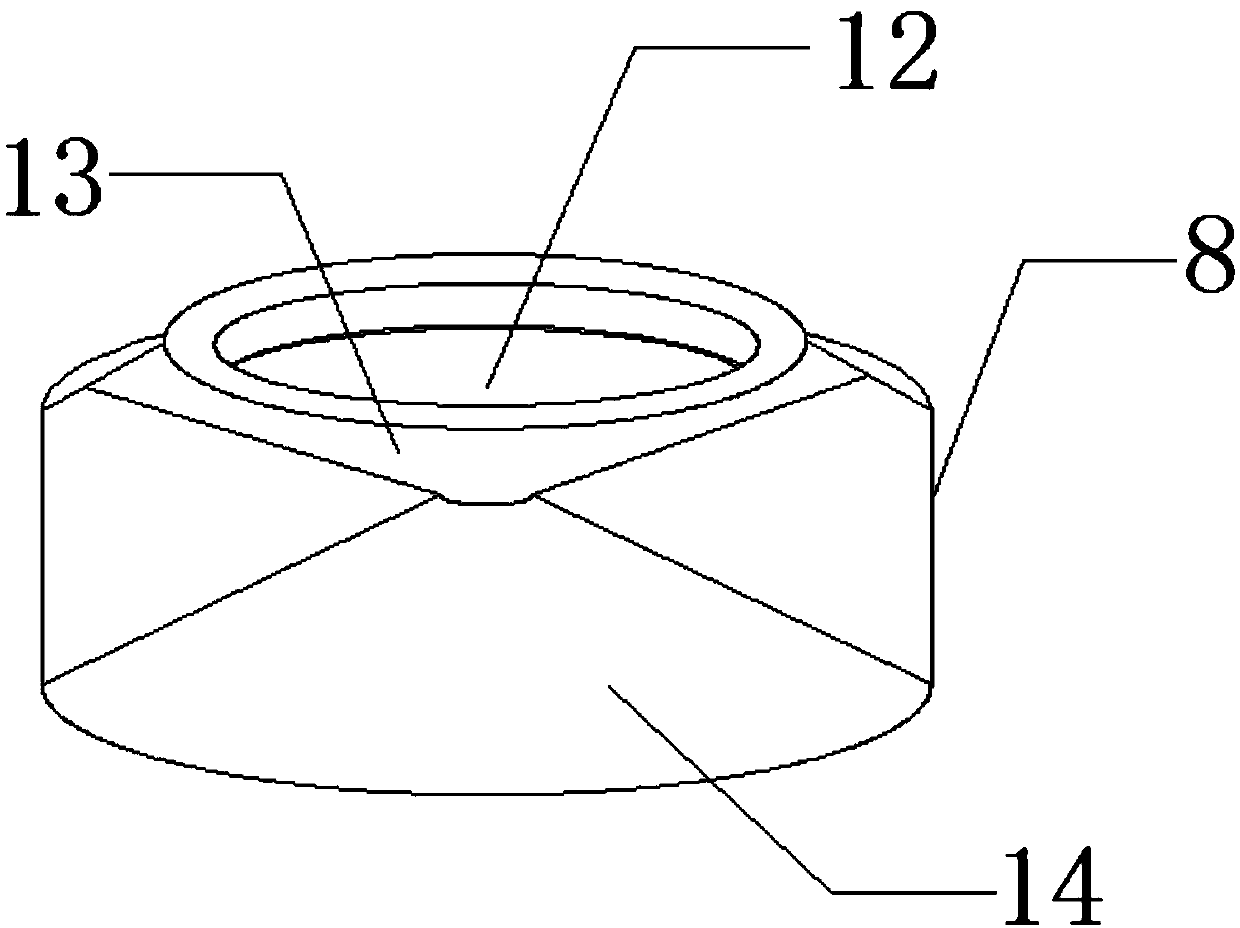

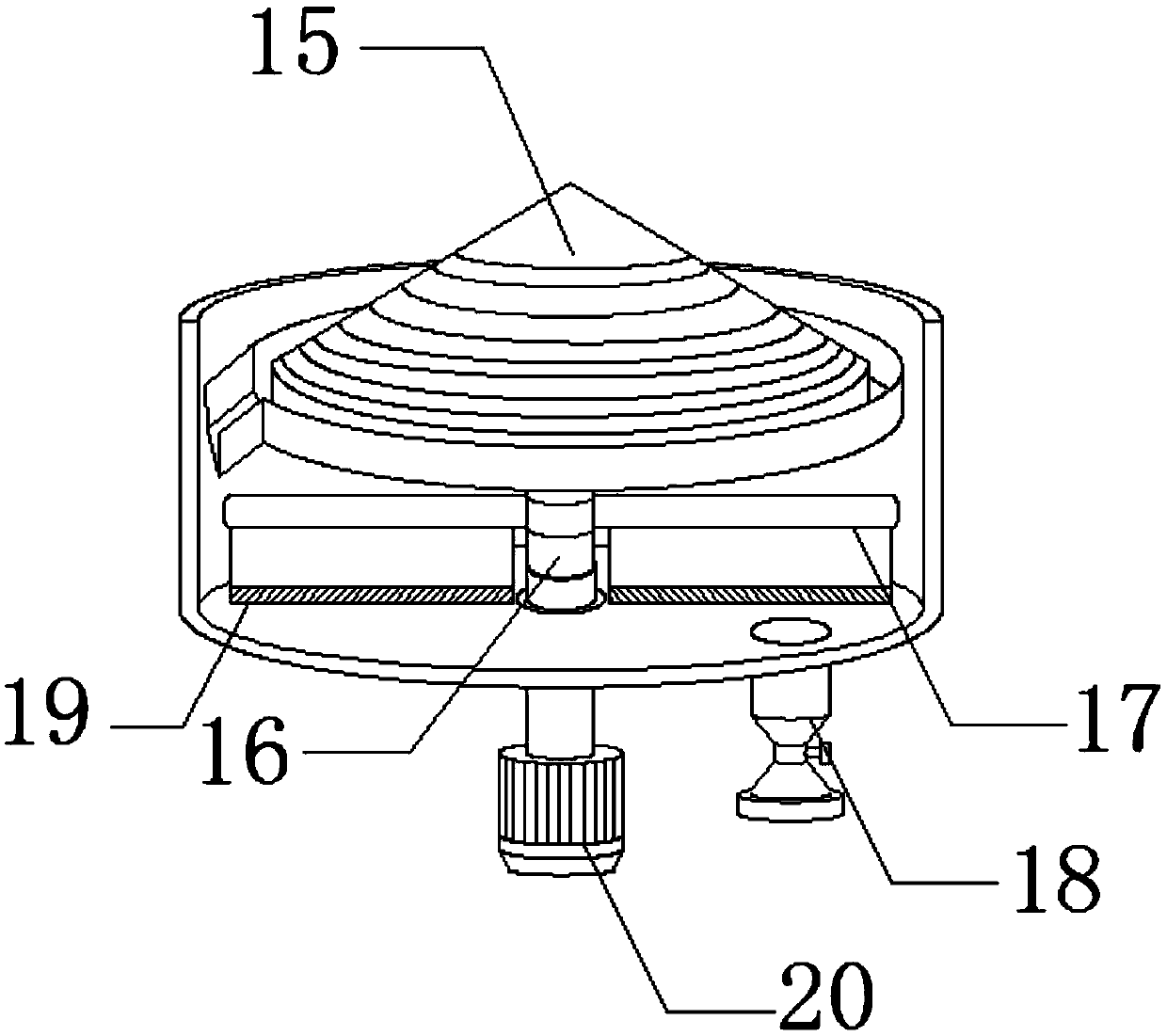

[0027] see figure 2 , image 3 and Figure 4 The difference from the above-mentioned embodiment is that one end of the auxiliary rod 5 is connected to one side of the hoop 10, and the other end is connected to the side wall of the vertical rod 1, so that the device can be laterally adjusted by the auxiliary rod 5 and the vertical column 1 during operation. support to prevent the grinding disc from shaking; the size of the upper grinding disc 8 is larger than that of the lower grinding disc 9, and the upper grinding disc 8 and the lower grinding disc 9 are flexibly connected, so that the upper grinding disc 8 and the lower grinding disc 9 can be separated to facilitate the cleaning of the internal grinding column; The side walls of the column 14 and the lower grinding column 15 are provided with spiral pins, and the upper grinding column 14 is engaged with the lower grinding column 15 through the pins, so that the upper grinding column 14 and the lower grinding column 15 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com