Center frame for machining strip-shaped workpieces

A strip workpiece and center frame technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of unable to keep the supporting claws stably fitted, the workpiece and the supporting claws are worn, and additional operations are added. Improve adjustment accuracy and service life, reduce wear and bumps, reduce the effect of additional operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

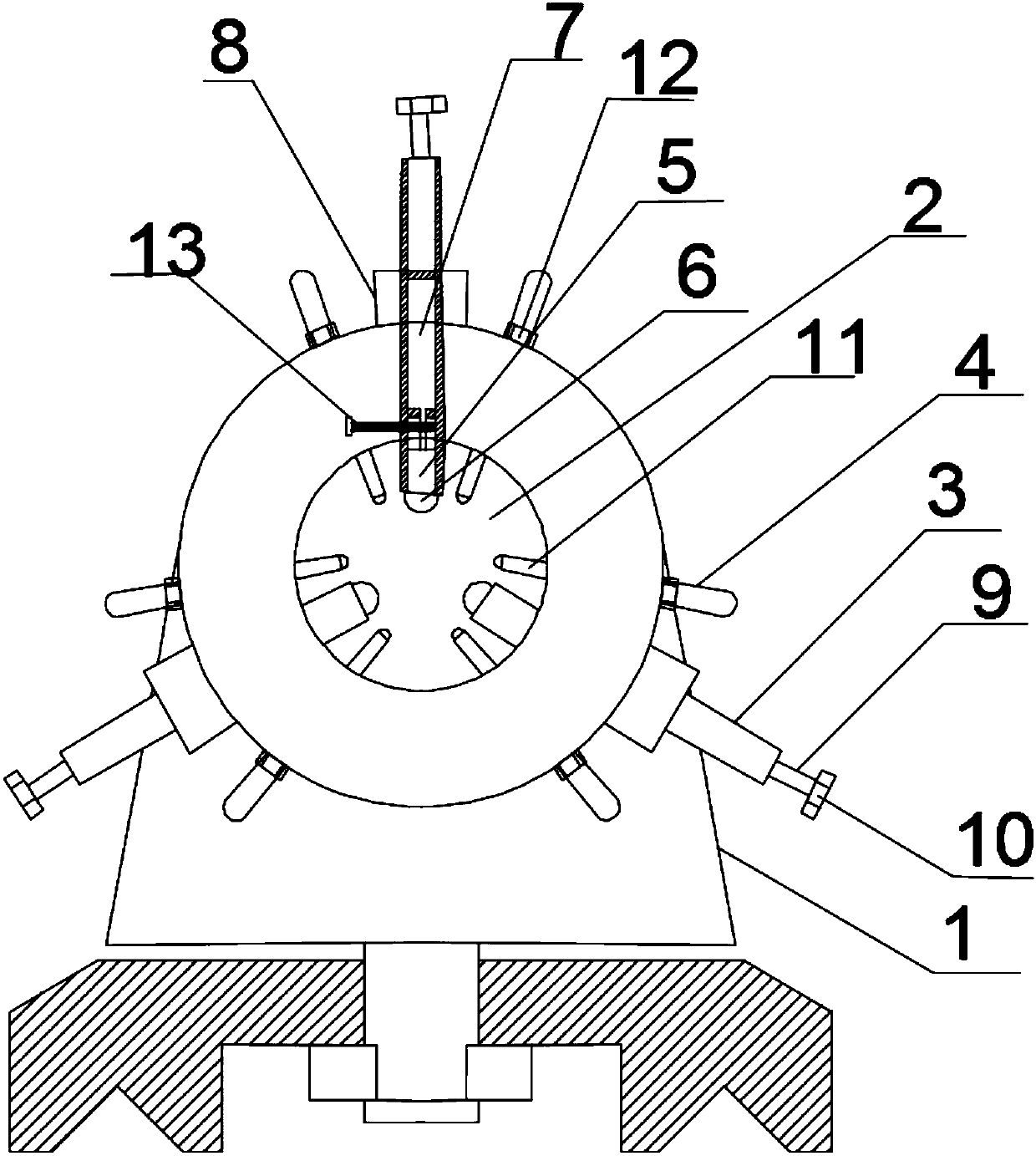

[0021] Such as figure 1 As shown, the present invention provides a center frame for processing strip-shaped workpieces, including a center frame body 1, a cavity portion 2 is arranged on the center frame body 1, the cavity portion is a hollow structure, and the center frame body 1 also includes three compression mechanisms 3 and six adjustment mechanisms 4, the three compression mechanisms 3 are uniformly arranged on the peripheral side of the cavity part 2, and the three compression mechanisms 3 and six adjustment mechanisms 4 One end of one end extends in the hollow structure of cavity part 2, and this end is provided with blind hole 5, and described blind hole 5 is provided with ball 6 or pulley, and the other of three pressing mechanisms 3 and six adjusting mechanisms 4 One end is provided with threads and is connected with the cavity part 2 through threads.

Embodiment 2

[0023] Such as figure 1 As shown, the present invention provides a center frame for processing strip-shaped workpieces, including a center frame body 1, a cavity portion 2 is arranged on the center frame body 1, the cavity portion is a hollow structure, and the center frame body 1 also includes three compression mechanisms 3 and six adjustment mechanisms 4, the three compression mechanisms 3 are uniformly arranged on the peripheral side of the cavity part 2, and the three compression mechanisms 3 and six adjustment mechanisms 4 One end of one end extends in the hollow structure of cavity part 2, and this end is provided with blind hole 5, and described blind hole 5 is provided with ball 6 or pulley, and the other of three pressing mechanisms 3 and six adjusting mechanisms 4 One end is provided with threads and is connected with the cavity part 2 through threads.

[0024] A lubricating oil chamber 7 is disposed inside the pressing mechanism 3 disposed directly above the cavity...

Embodiment 3

[0026] Such as figure 1 As shown, the present invention provides a center frame for processing strip-shaped workpieces, including a center frame body 1, a cavity portion 2 is arranged on the center frame body 1, the cavity portion is a hollow structure, and the center frame body 1 also includes three compression mechanisms 3 and six adjustment mechanisms 4, the three compression mechanisms 3 are uniformly arranged on the peripheral side of the cavity part 2, and the three compression mechanisms 3 and six adjustment mechanisms 4 One end of one end extends in the hollow structure of cavity part 2, and this end is provided with blind hole 5, and described blind hole 5 is provided with ball 6 or pulley, and the other of three pressing mechanisms 3 and six adjusting mechanisms 4 One end is provided with threads and is connected with the cavity part 2 through threads.

[0027] A lubricating oil chamber 7 is disposed inside the pressing mechanism 3 disposed directly above the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com