Special tool for on-column switch live lap joint

A technology for pole-mounted switches and special tools, which is applied to switchgear, electrical components, etc., can solve problems such as wear or damage, reduced creepage distance of insulating blanket needles, and difficult operation, so as to reduce production difficulty and production cost , Good insulation and shielding effect, convenient and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

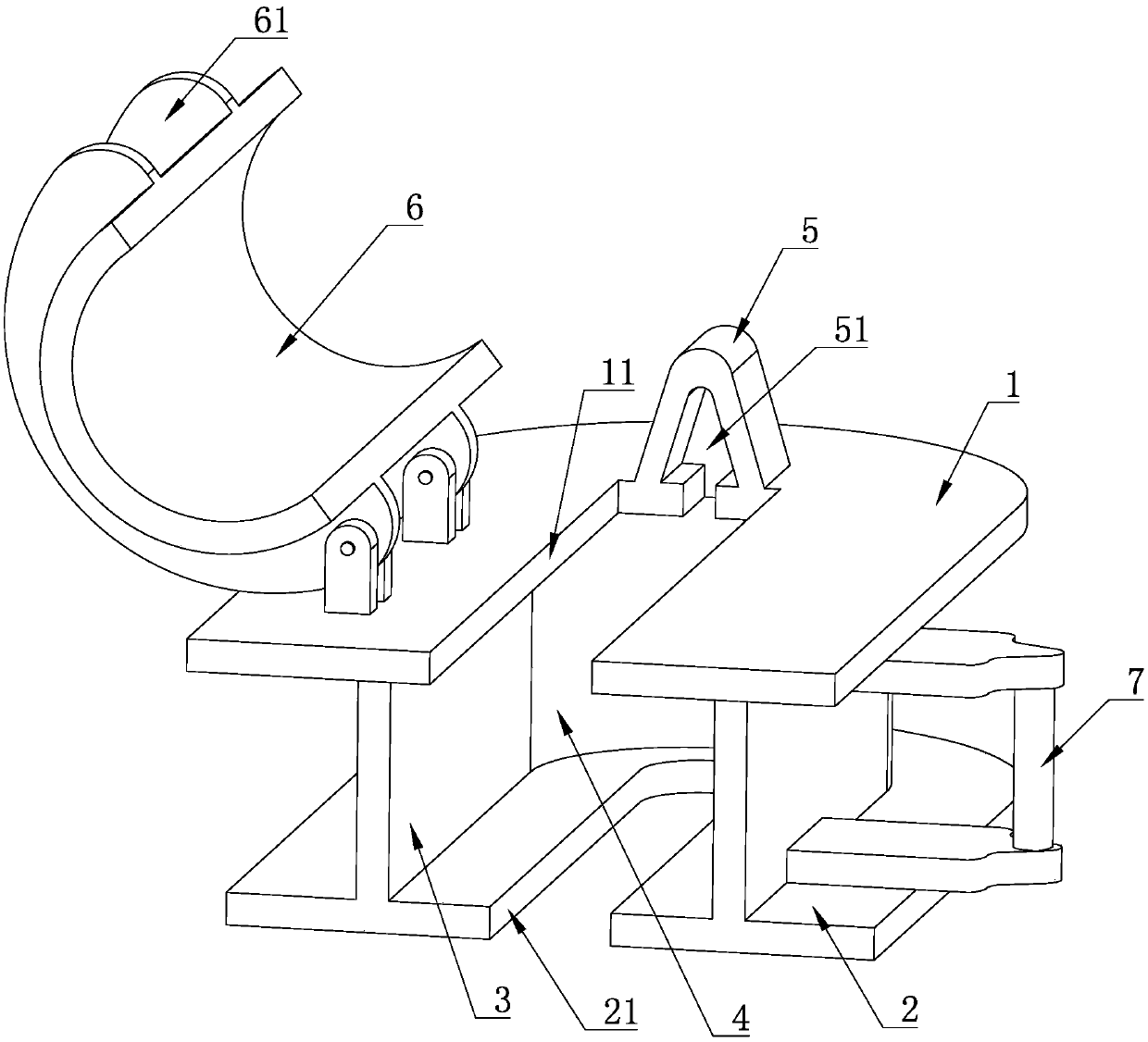

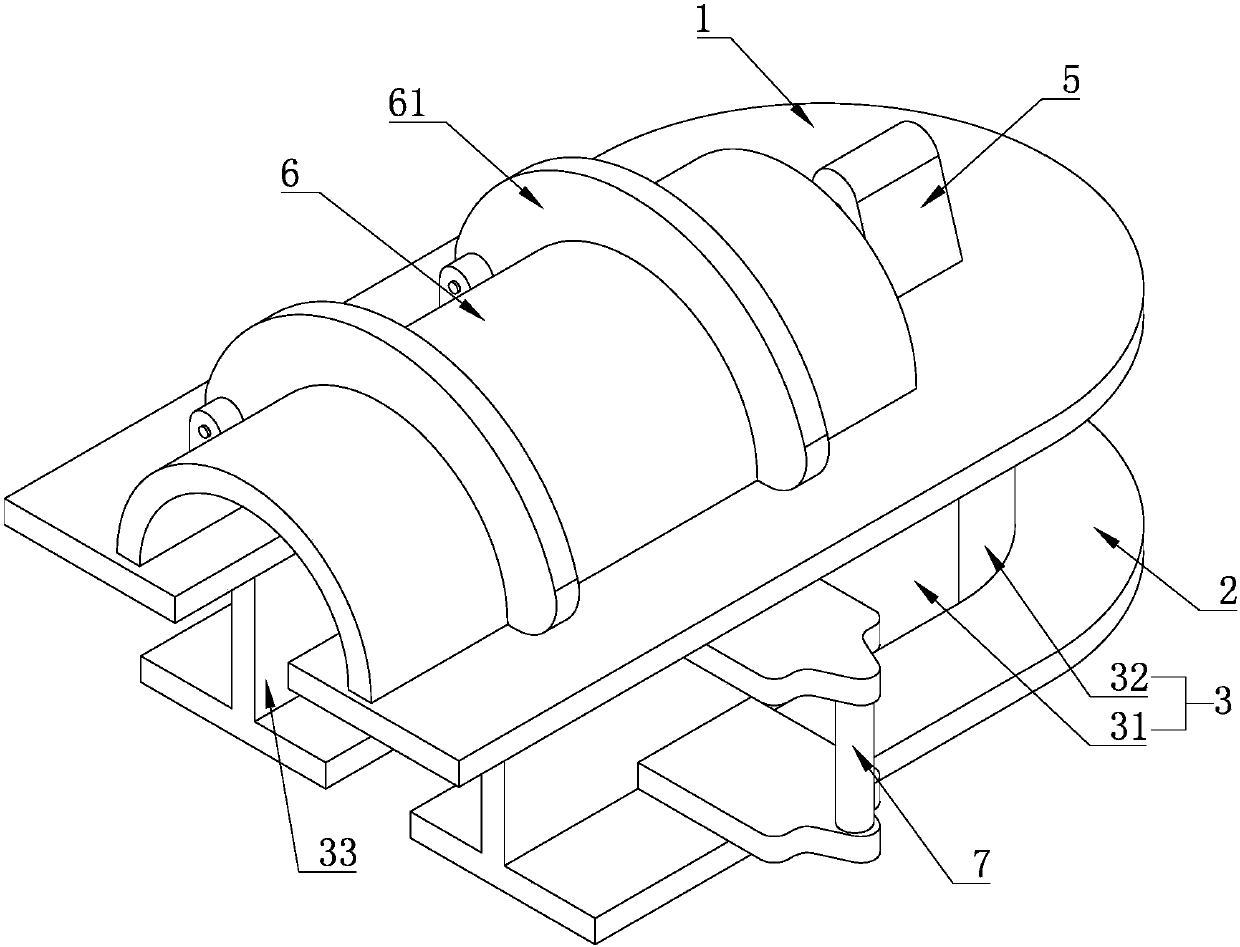

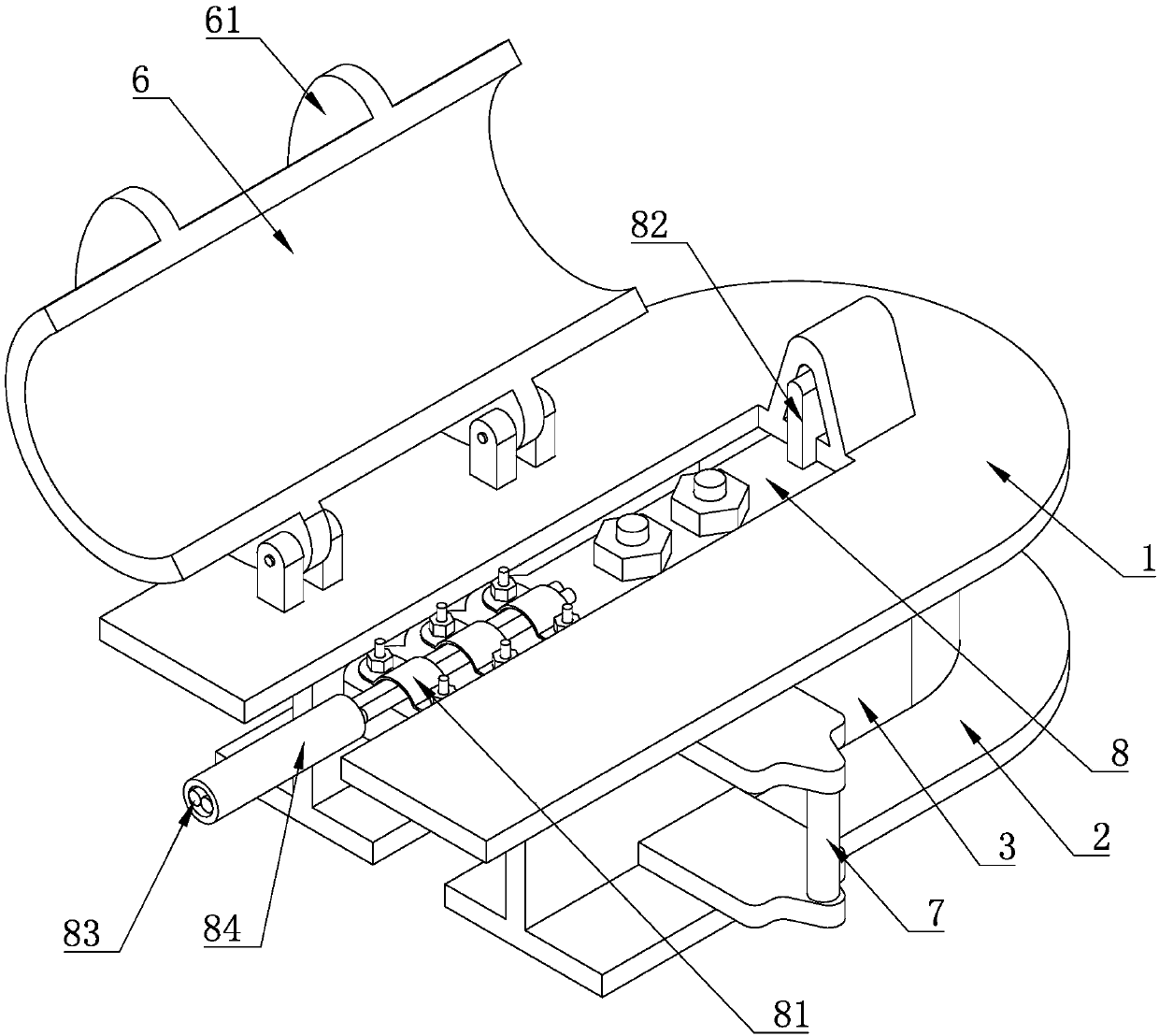

[0031] A special tool for live lapping of the switch on the pole, including a top plate 1, a bottom plate 2, and a side plate 3 connected between the top plate 1 and the bottom plate 2. The inner walls of the top plate 1, bottom plate 2, and side plate 3 are enclosed to accommodate the pile head of the upper lead wire. The cavity 4, the side plate 3 is a U-shaped plate, including two parallel flat plates 31 and an arc-shaped plate 32, one end of the two flat plates 31 is connected with the arc-shaped plate 32, and the other end forms an opening 33 communicating with the receiving chamber 4 and the outside world , one end of the flat plate 31 close to the opening 33 is aligned with the end of the bottom plate 2, the top plate 1 and the bottom plate 2 are respectively provided with a first installation groove 11 and a second installation groove 21 for the upper lead pile head to pass through, the first installation groove 11 and the second installation groove 21. The notch of the...

Embodiment 2

[0036] In this embodiment, a detachable structure is formed between the shielding cover 6 and the top plate 1, the cross section of the shielding cover 6 is arc-shaped, and a flange 61 is arranged on the outside of the shielding cover 6, and one end of the arc-shaped shielding The flange 61 is hinged with the top plate 1 .

[0037] When insulating and shielding the upper lead pile head of the switch on the column, the shielding cover 6 can be rotated relative to the top plate 1, so that the shielding cover 6 can be opened, and the shielding cover 6 is first opened along the hinge axis, and then closed after the installation Cover 6 is enough, open shielding cover 6, can observe the position of the wiring board of upper lead wire pile head through the first installation groove 11, also can determine whether there is the generation of damage situation, installation is more convenient and accurate; Flange 61 has strengthened shielding cover 6 strength and the contact area between...

Embodiment 3

[0039]The difference between the present embodiment and the second embodiment is that the shielding cover 6 is provided with a buckle, and the top plate 1 is provided with a slot that cooperates with the buckle.

[0040] When the shielding cover 6 is closed on the top plate 1, the buckle and the slot fit together so that the shielding cover 6 will not be easily opened under non-artificial conditions after the buckle, and the insulating shielding effect is better and more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com