A high-pressure steamed stalk processing technology

A technology of cut stems and pressed stems, which is applied in the field of process treatment of tobacco products, can solve the problems of complicated and repeated technological process of cut stems, low production efficiency of cut stems, and ineffective utilization of cut stems, so as to simplify the technological process and improve the cut stems. Production efficiency, the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

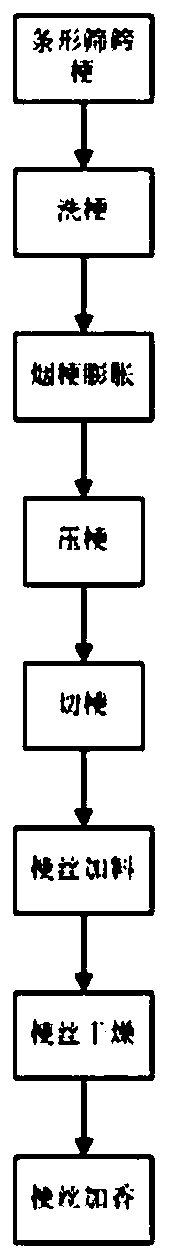

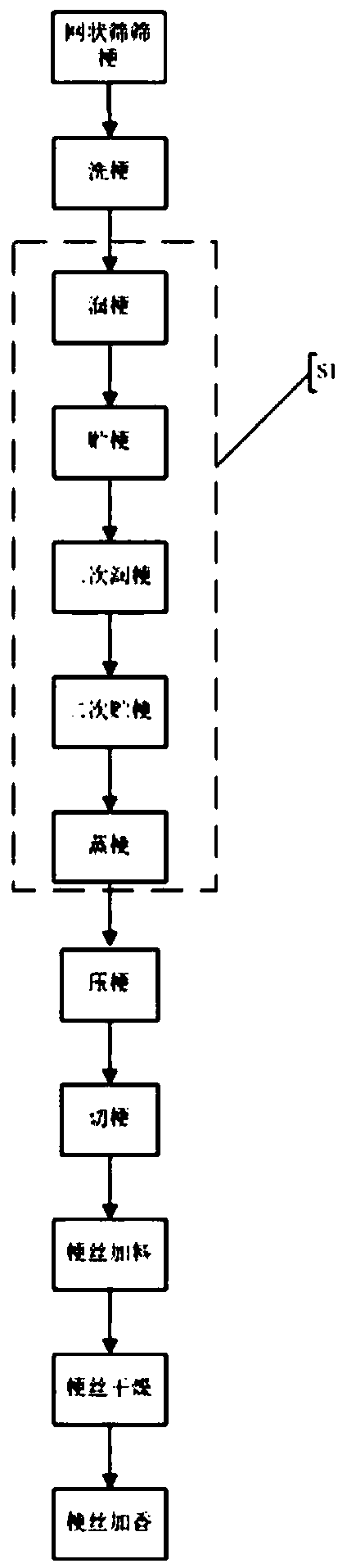

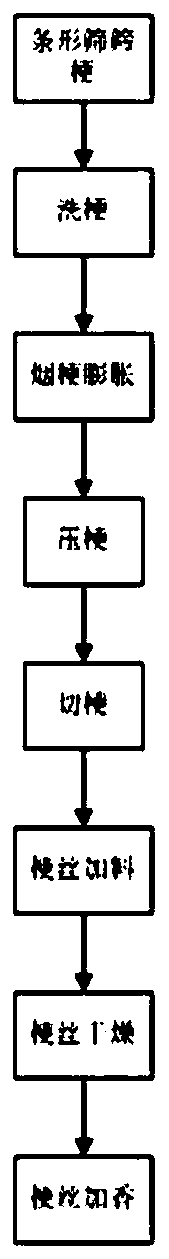

[0013] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 The process for processing shredded stems by high pressure steaming includes the steps of screening stems, washing stems, expanding tobacco stems, pressing stems, cutting shredded stems, feeding shredded stems, drying shredded stems, and flavoring shredded stems.

[0014] Tobacco stem raw materials pass through double-layer strip sieves, the distance between the bars of the upper sieve is 12mm, and the distance between the sieve bars of the lower sieve is 10mm, so as to screen out the stem tips in the stems, improve the purity of the stems, and improve the utilization efficiency of the stems without sieving fine stems. After sieving, the tobacco stems enter the stem washing process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com