Two-dimensional laser dynamic detection device and method of steel rail profiles and corrugations

A two-dimensional laser and detection device technology, applied to measuring devices, optical devices, railway vehicle shape measuring devices, etc., can solve the problems of low detection efficiency, poor reliability of measurement data, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

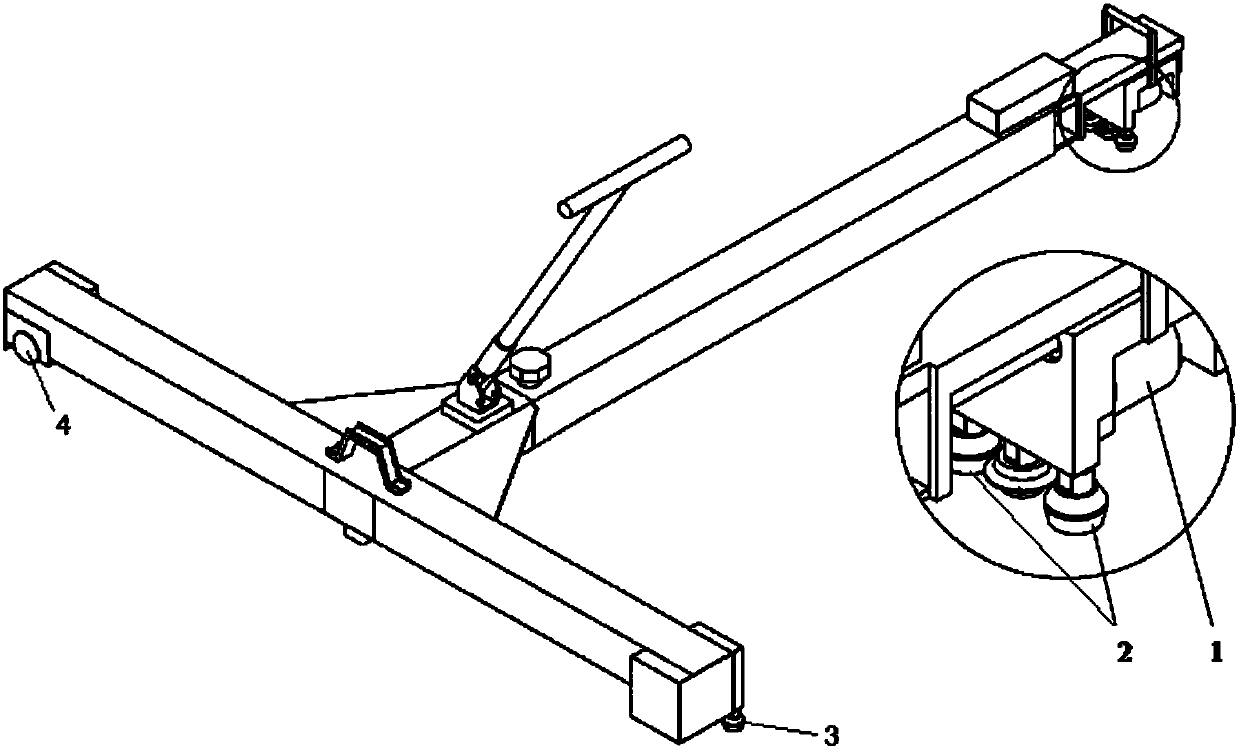

[0094] see Figure 15 , the detection device of this embodiment includes a two-dimensional laser displacement sensor, an adjustable bracket, a traveling trolley, a DC power supply, an encoder, an industrial computer, and rail profile detection software. The traveling trolley is composed of T-shaped structural parts, traveling wheels, and guide wheels. Its main function is to carry a two-dimensional laser displacement sensor to realize longitudinal movement along the rail.

[0095] When the device of this embodiment detects the profile of the rail, it includes the following processes:

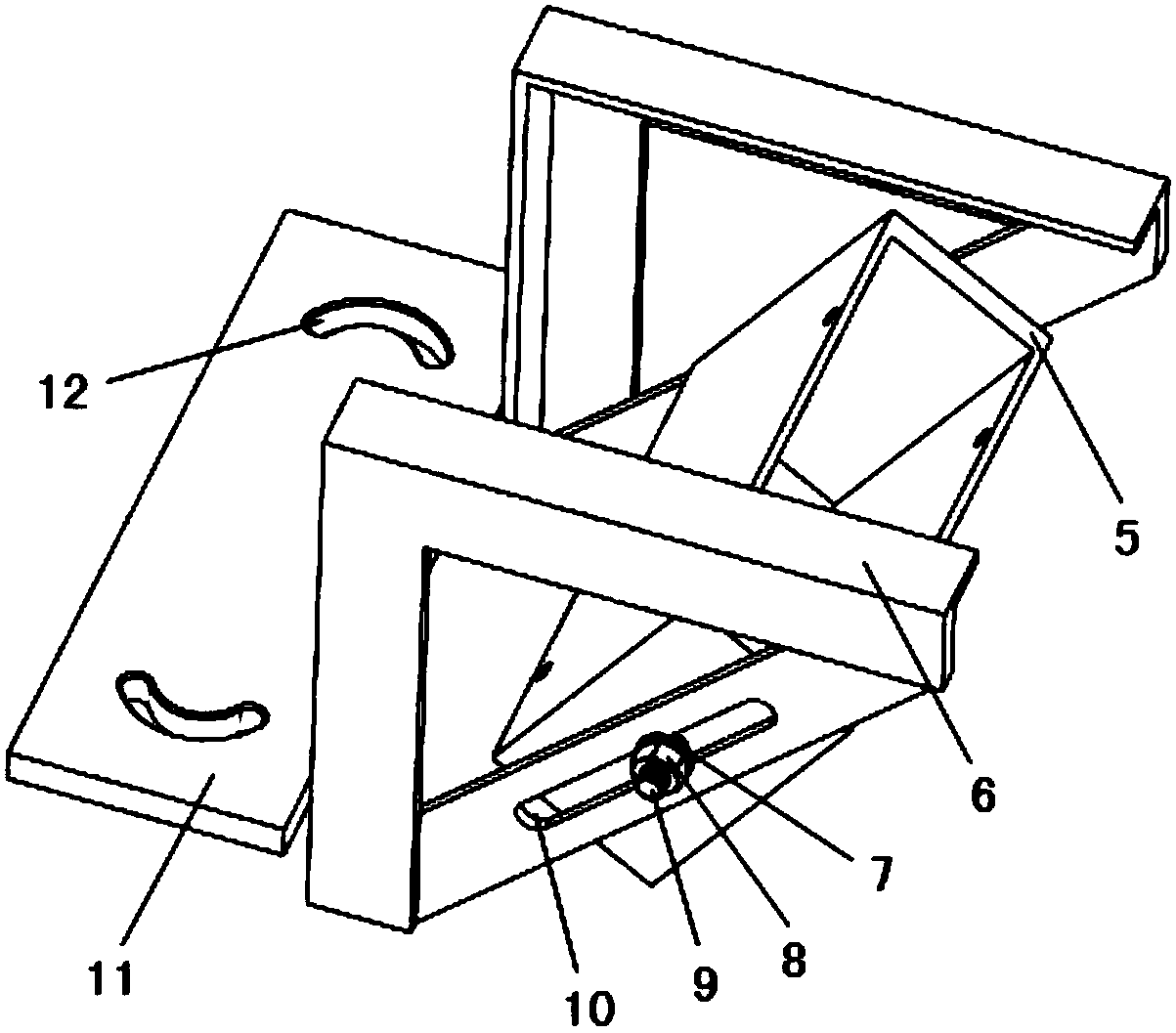

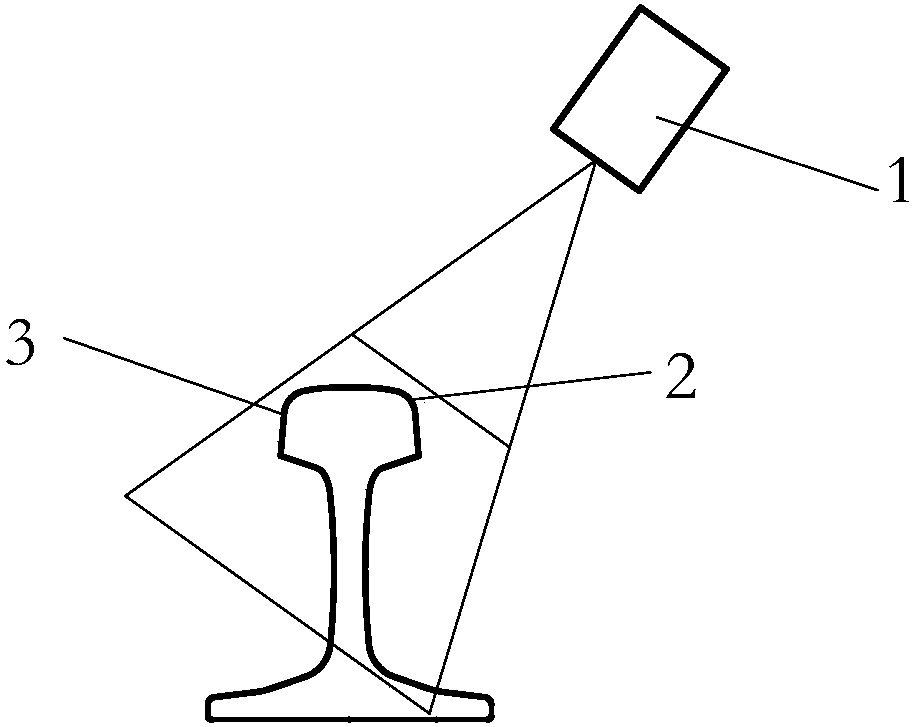

[0096] 1) The adjustable bracket is fixed on the trolley through the fixing plate and screws. When working, the two-dimensional laser displacement sensor is placed in the installation box, and the laser plane of the two-dimensional laser displacement sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com