A kind of concrete structure repair agent and its preparation method, application method

A technology for concrete structure and repairing agent, applied in the field of building materials, can solve the problems of inability to formulate repairing agent, poor controllability of setting time, poor engineering economy, etc., and achieves good market promotion value, good construction stability, and repairing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the preparation of 1000kg concrete structure repair agent product as an example.

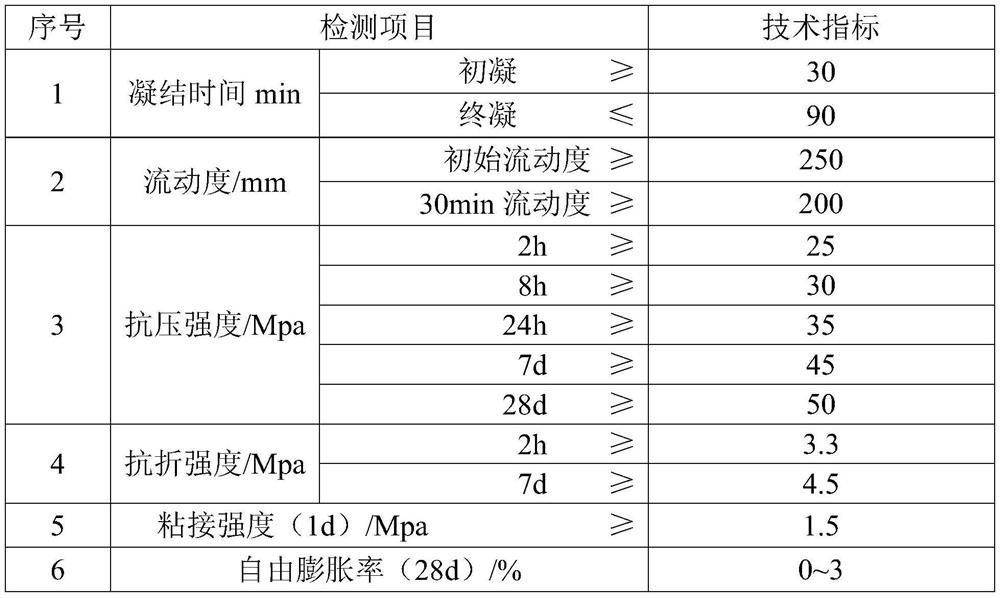

[0026] Prepare the concrete structure repair agent product, the proportion is calculated according to the weight percentage, put into the mixing tank 450kg of sulfoaluminate cement clinker, 500kg of ordinary portland cement clinker, 10kg of polycarboxylate superplasticizer, and 10kg of emulsified silicone oil , 10kg of high-carbon alcohol fatty acid ester compound, 10kg of polydimethylsiloxane, and 10kg of methyl cellulose, in which the sulphoaluminate cement clinker is produced by replacing 50% of aluminum ore with aluminum slag, and its setting time: initial Set no earlier than 15 minutes, final set no later than 60 minutes, its specific surface area ≥ 400m 2 / kg. The setting time of ordinary Portland cement clinker: the initial setting is not earlier than 45 minutes, the final setting is not later than 600 minutes, and its specific surface area is ≥ 300m 2 / kg. The polycarboxyl...

Embodiment 2

[0028] Take the preparation of 1000kg concrete structure repair agent product as an example.

[0029] Prepare the concrete structure repair agent product, and its proportioning is calculated according to the weight percentage, put into the mixing tank 500kg of sulfoaluminate cement clinker, 450kg of ordinary Portland cement clinker, 20kg of polycarboxylate water reducer, high carbon alcohol 20kg of fatty acid ester compound and 10kg of hydroxyethyl methylcellulose were mixed evenly to prepare the concrete structure repair agent product of this embodiment. Then pack it into 25±0.25kg per bag or 50±0.5kg per bag.

Embodiment 3

[0031] Take the preparation of 1000kg concrete structure repair agent product as an example.

[0032] Prepare the concrete structure repair agent product, and its proportioning is calculated according to the weight percentage, put into the mixing kettle 500kg of sulphoaluminate cement clinker, 400kg of ordinary Portland cement clinker, 30kg of polycarboxylate superplasticizer, polyoxyethylene 20kg of polyoxypropylene pentaerythritol ether, 20kg of polyoxyethylene polyoxypropanol amine ether, 10kg of carboxymethyl cellulose, 10kg of ethyl cellulose, 10kg of hydroxypropyl methyl cellulose, and stir evenly to obtain the concrete of this embodiment Structural Repair Products. Then pack it into 25±0.25kg per bag or 50±0.5kg per bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com