Glass fiber reinforced polyurethane

A technology of glass fiber and polyurethane, which is applied in the field of insulating elastic gaskets for high-speed rail rails, can solve the problems of rubber gaskets such as low elastic modulus, insufficient impact resistance, and insufficient rigidity, so as to ensure stability, good aging resistance, and elasticity The effect of large modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

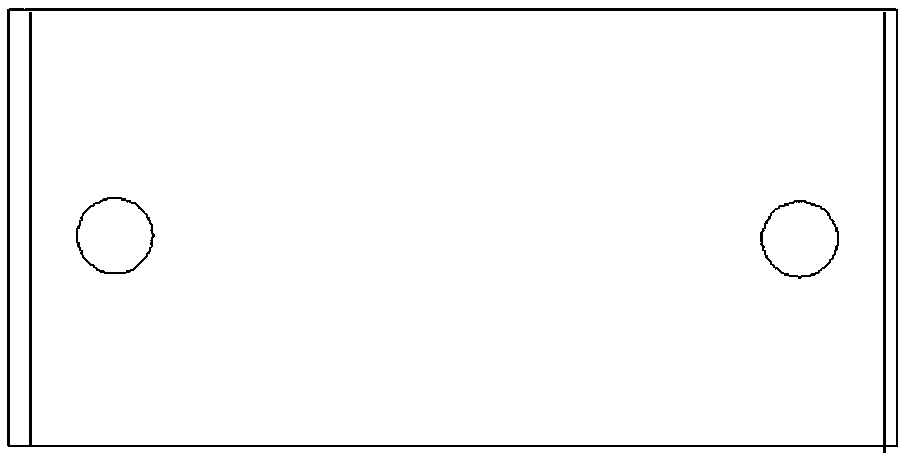

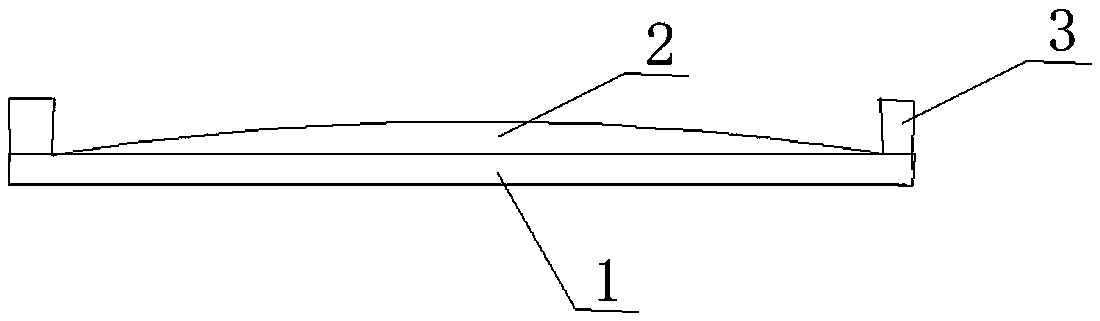

[0029] Specific embodiment 1: as figure 1 figure 2 As shown, this embodiment discloses a high-speed rail rail insulating elastic sheet, including a bottom layer 1 and a surface layer 2. The surface layer 2 is an arc-shaped structure with a thick middle and thin sides, and the thickness in the middle of the elastic sheet is 10 mm. 1 has a thickness of 3mm.

[0030] The two ends of the high-speed rail insulating elastic sheet are provided with a convex layer 3, and the height of the convex part is 2mm. The surface layer 2 is provided with a textured structure, and the textured depth is 1mm. The textured structure can be It is in any shape, and the surface of the bottom layer 1 is provided with a groove structure.

[0031] The high-speed rail rail insulation elastic sheet is a glass fiber reinforced polyurethane material, and the preparation method is as follows:

[0032] Step 1: Preparation of prepreg, melting the resin matrix, coupling agent, and toughening agent in a melti...

specific Embodiment 2

[0037] Specific embodiment 2: as figure 1 figure 2 As shown, this embodiment discloses a high-speed rail rail insulating elastic sheet, including a bottom layer 1 and a surface layer 2. The surface layer 2 is an arc-shaped structure with a thick middle and thin sides, and the thickness in the middle of the elastic sheet is 15 mm. 1 has a thickness of 10mm.

[0038] The two ends of the high-speed iron rail insulating elastic sheet are provided with a convex layer 3, and the height of the convex part is 5 mm. The surface layer 2 is provided with a textured structure, and the textured depth is 5 mm. The textured structure can be It is in any shape, and the surface of the bottom layer 1 is provided with a groove structure.

[0039] The high-speed rail rail insulation elastic sheet is a glass fiber reinforced polyurethane material, and the preparation method is as follows:

[0040] Step 1: Preparation of prepreg, melting the resin matrix, coupling agent, and toughening agent in...

specific Embodiment 3

[0045] Specific embodiment 3: as figure 1 figure 2 As shown, this embodiment discloses a high-speed rail rail insulating elastic sheet, including a bottom layer 1 and a surface layer 2. The surface layer 2 is an arc-shaped structure with a thick middle and thin sides. The thickness in the middle of the elastic sheet is 12mm. 1 has a thickness of 7mm.

[0046] The two ends of the high-speed iron rail insulating elastic sheet are provided with a convex layer 3, and the height of the convex part is 3mm. The surface layer 2 is provided with a textured structure, and the textured depth is 3mm. The textured structure can be It is in any shape, and the surface of the bottom layer 1 is provided with a groove structure.

[0047] The high-speed rail rail insulation elastic sheet is a glass fiber reinforced polyurethane material, and the preparation method is as follows:

[0048] Step 1: Preparation of prepreg, melting the resin matrix, coupling agent, and toughening agent in a melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com