Method for accelerating aging of T/P92 heat-resistant steel

A technology for accelerated aging and heat-resistant steel, applied in the field of heat treatment of steel materials, it can solve the problems of short service time and inability to obtain aging structure, evaluation, and inability to age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

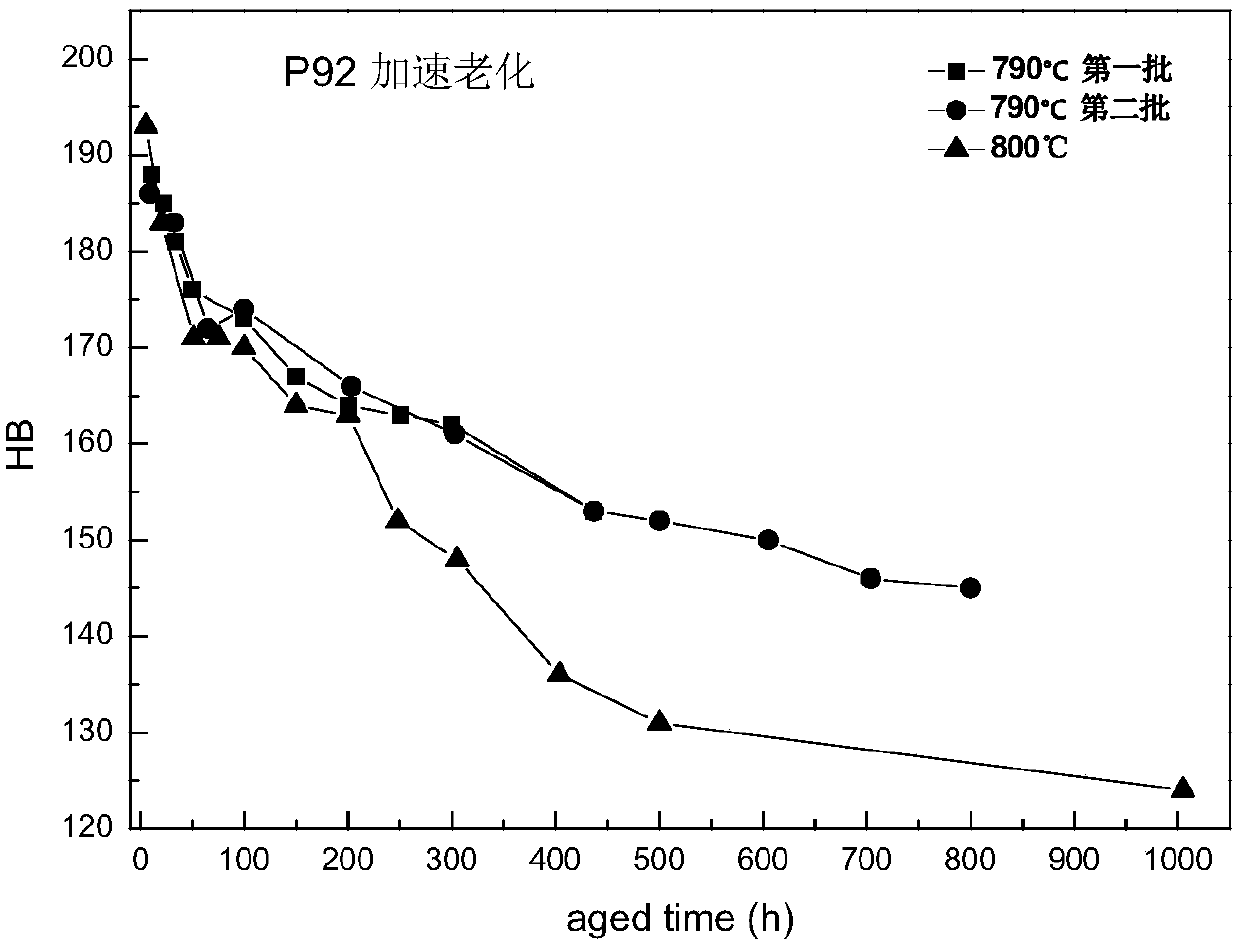

[0020] The materials used in the present invention are obtained from the actual cutting of the main steam pipe of P92 heat-resistant steel in a supercritical power plant of a certain power plant. After re-heat treatment, accelerated aging aging was carried out and compared with its original service state. Firstly, carry out the high-temperature rapid short-term accelerated aging experiment of the matrix and carbide, and choose AC 1 Aging is carried out at a temperature (800°C) of 30°C below the point (about 830°C) for 305 hours. After the aging is completed, aging at a lower temperature (650°C) is used to rapidly precipitate the Laves phase, and finally realize the aging structure equivalent to the actual working conditions in different periods.

[0021] like figure 1 As shown, the change in hardness of P92 aged at 790°C and 800°C after using the present invention, under these two schemes, the change law of hardness conforms to the law of tissue degradation, and the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com