Large-tonnage steel box girder pushing device, pushing system and pushing method

A technology of a jacking device and a steel box girder, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem that it is difficult to control the steel box girder to stop at the target position, so as to improve the jacking and moving efficiency, improve the The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

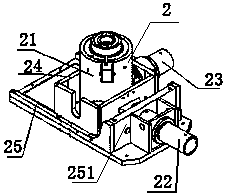

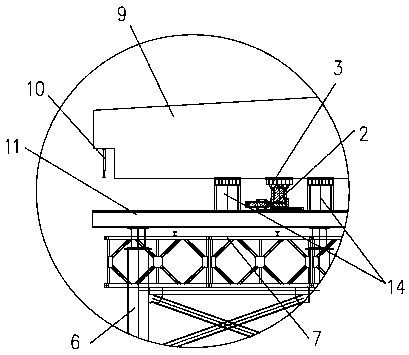

[0061] Such as Figure 1-5 As shown, the large-tonnage steel box girder pushing device 2 includes jacking telescopic equipment for jacking up the steel box girder 1, flat push telescopic equipment for pushing the steel box girder 1 to move to the target position, and deviation correcting telescopic equipment, The jacking equipment, flat push telescopic equipment and deviation correcting telescopic equipment are all installed on the sliding box body 24, and the bottom of the sliding box body 24 is provided with a sliding base 25 for sliding, and the horizontal pushing telescopic equipment, deviation correcting telescopic equipment The opposite ends of the equipment are connected to the sliding box body 24 and the sliding base 25 respectively, so that the sliding base 25 and the sliding box body 24 can move relatively. The jacking telescopic equipment is a jacking cylinder 21. The horizontal pushing telescopic equipment is a horizontal pushing oil cylinder 22, and the deviation ...

Embodiment 2

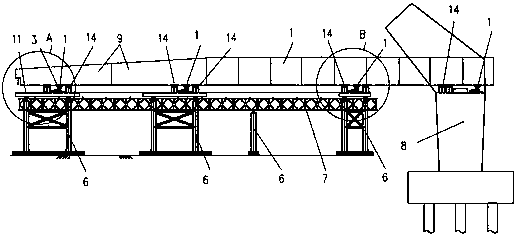

[0067] Such as Figure 1-5As shown, the large-tonnage steel box girder pushing system includes a plurality of supports 6 and equipment platforms 7 installed on the plurality of supports 6, and the supports 6 are erected on the route where the steel box girder 1 moves to the target position. The above-mentioned pushing device 2 is installed on the top of each support 6 and the abutment 8, and the pushing device 2 is installed on the top of a plurality of supports 6, thereby forming a plurality of pushing devices 2 to simultaneously press the steel box The beam 1 completes the jacking, which avoids the problem of unbalanced force on the steel box girder 1 due to the partial installation of the jacking device, which makes the overall force of the steel box girder 1 more balanced, and reduces the weight of each jacking device. 2 The load carried.

[0068] Since the steel box girder 1 is constantly moving towards the target position during the pushing process, the front end of the...

Embodiment 3

[0081] Such as Figure 6-9 As shown, the large-tonnage steel box girder pushing method, when using the pushing device 2 in the embodiment 1 to push the steel box girder 1, the jacking telescopic equipment, flat pushing telescopic equipment and The deviation correcting telescopic equipment is respectively set as jacking cylinder 21, flat pushing cylinder 22 and deviation correcting cylinder 23, and the pushing is completed according to the following steps:

[0082] a. Jack up the steel box girder 1, open the jacking oil cylinder 21, so that the jacking oil cylinder 21 rises and lifts the steel box girder 1 away from the support seat 14;

[0083] b. Push the steel box girder 1, open the horizontal push cylinder 22, so that the steel box girder 1 and the sliding box body 24 move forward as a whole, until the horizontal push cylinder 22 completes a stroke;

[0084] c. The jacking device 2 is reset, and the jacking cylinder 21 is opened to lower the steel box girder 1 as a whole u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com