Steel structure anti-seismic frame structure and steel structure fabricated anti-seismic building

The technology of seismic frame and steel structure is applied in the field of steel structure seismic frame structure and steel structure prefabricated seismic building, which can solve the problems of insufficient seismic performance and achieve the effect of high construction efficiency and good seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

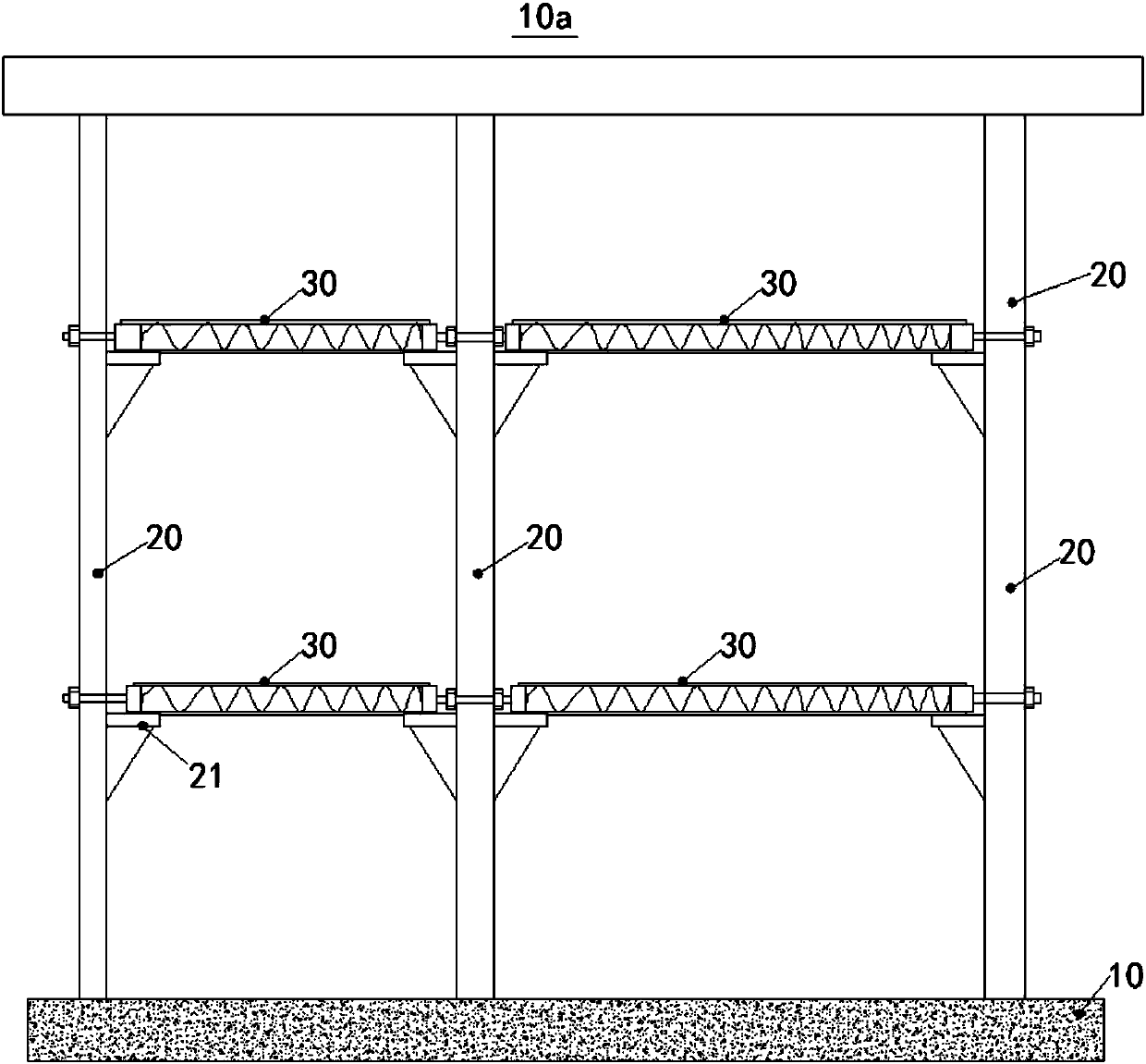

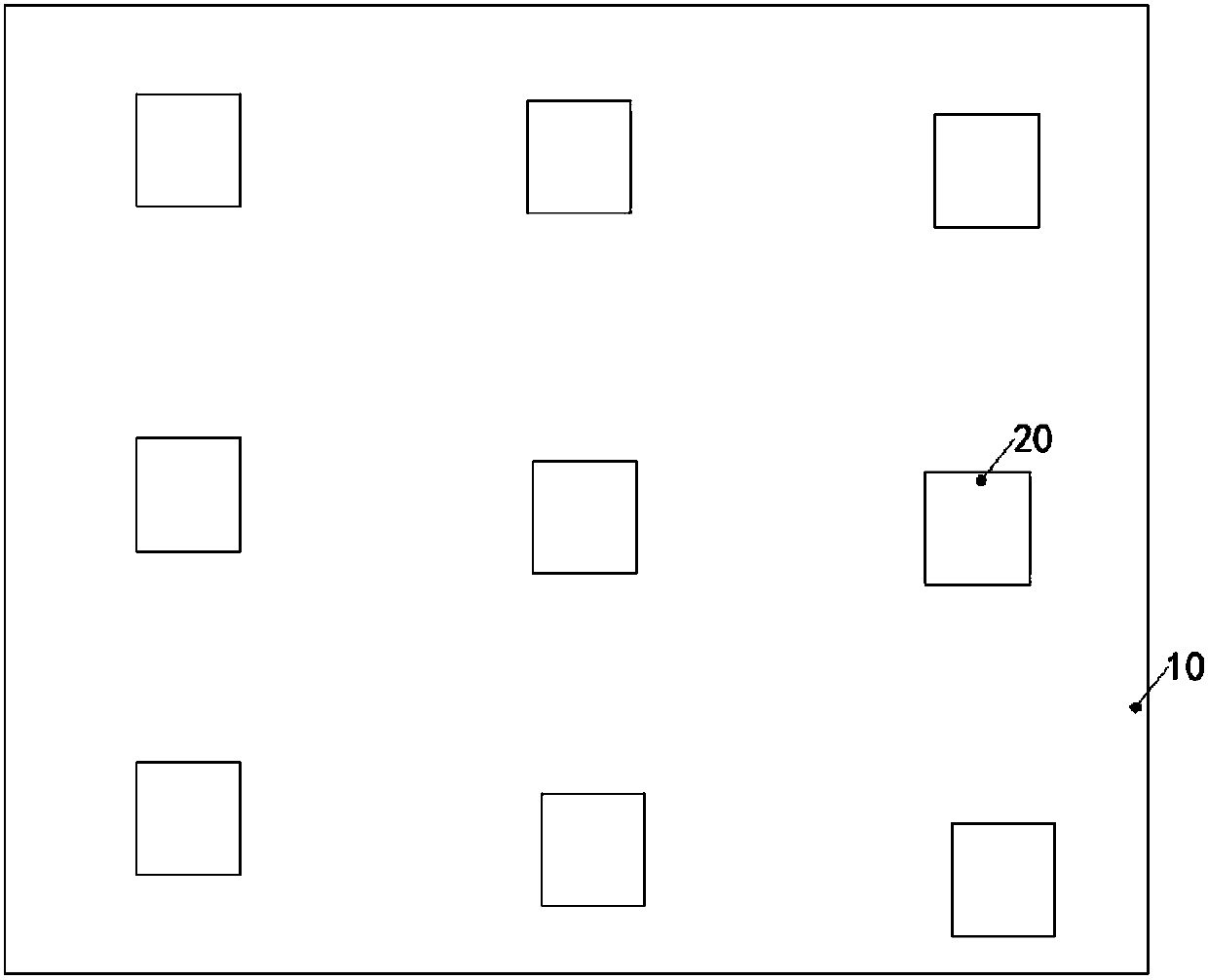

[0046] figure 1 It is a schematic diagram of the steel structure anti-seismic frame structure 10a in the embodiment of the present invention. see figure 1 , the steel structure anti-seismic frame structure 10a in this embodiment includes a base plate 10, a plurality of steel columns 20 spaced apart from each other and vertically connected to the base plate 10; adjacent steel columns 20 pass through steel beams along the horizontal direction 30 is connected; a plurality of steel columns 20 and a plurality of steel beams 30 are connected to each other to form a steel structure frame form. The distribution mode of the steel columns 20 can be set according to the actual spatial arrangement and the overall force configuration, such as figure 2 As shown, it is generally distributed in a matrix shape, and a steel column 20 is arranged at the corner of each individual space.

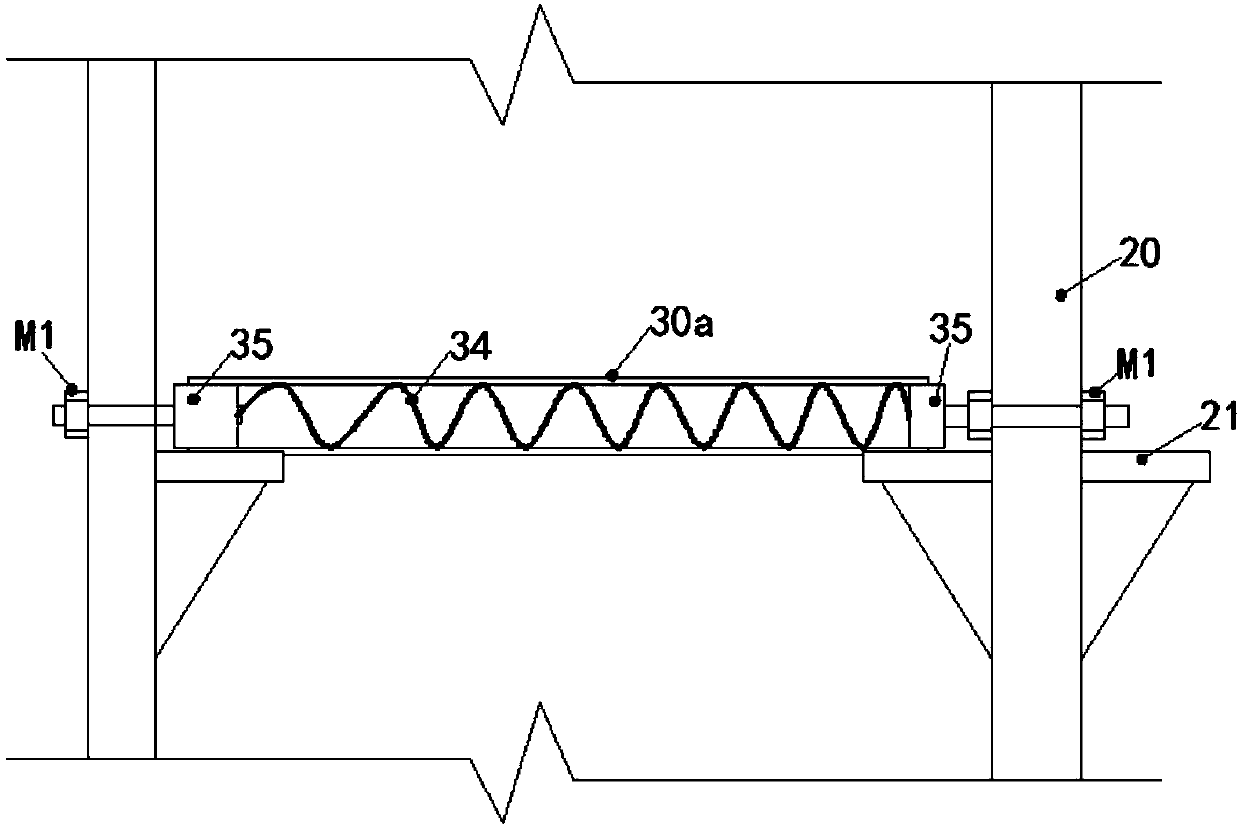

[0047] image 3 The connection node form between the steel beam 30 and the steel column 20 in the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com