Device for filling a can with a sliver

A technology for fiber strips and filling strips, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc., and can solve problems such as strip breakage and fiber strip drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

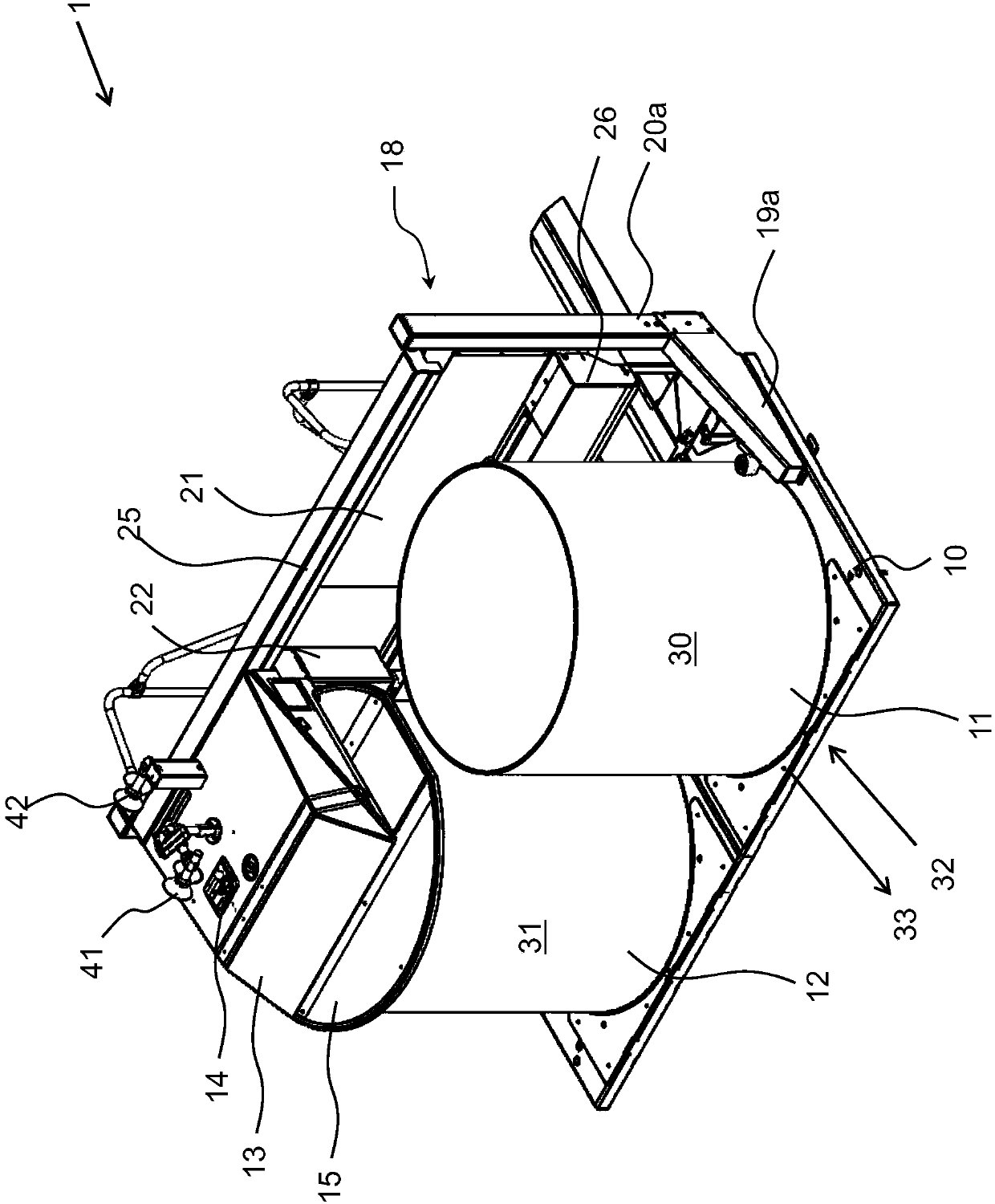

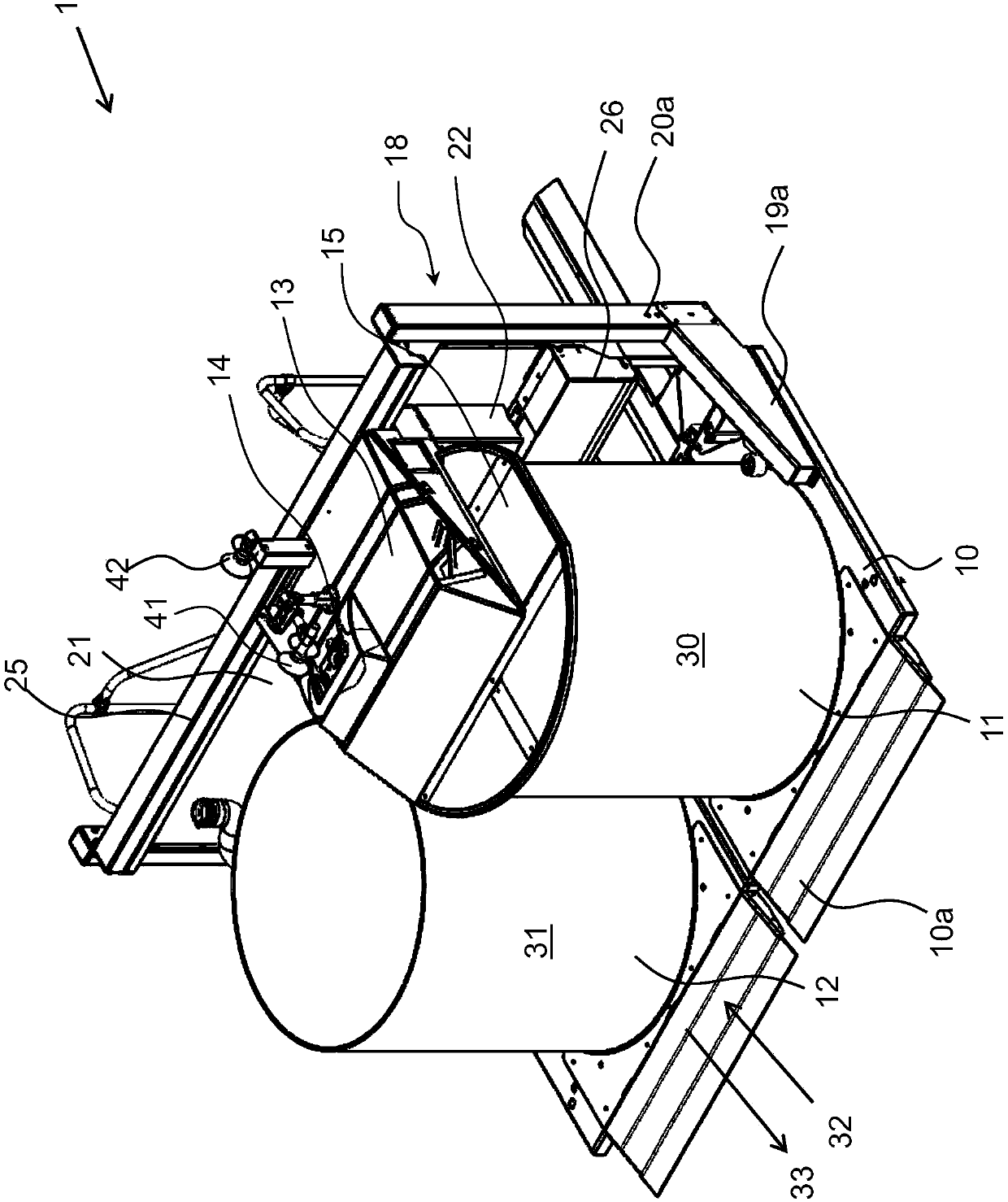

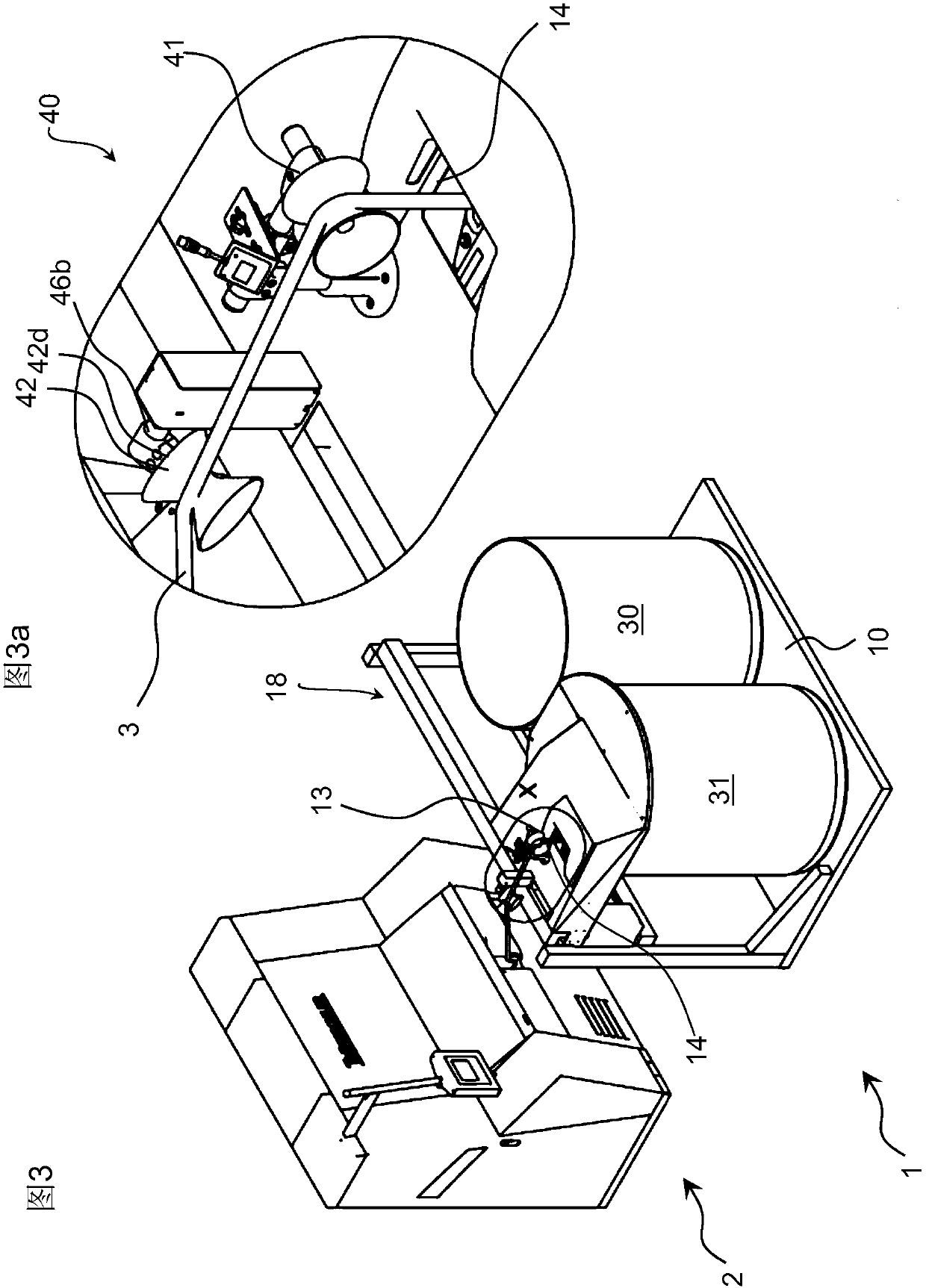

[0027] according to Figure 1 to Figure 2 The can changer 1 of the invention basically comprises a rectangular base plate 10 in which two can discs 11 , 12 are rotatably arranged. The base plate 10 serves as a rest or movement surface for cans which are moved or transported transversely to the longitudinal direction of the base plate 10 . The base plate 10 is substantially of a size or length suitable for receiving two cans side by side. exist figure 1 In the view of , a full or to-be-filled can 31 is shown on the left, and an empty can 30 is shown on the right. Each can 30 , 31 rests on its own rotatably driven can drum 11 , 12 , the drive of which is integrated in the base plate 10 . A coiling head 13 with an integrated turntable 14 is arranged above the full or to-be-filled can 31 . The fiber slivers, not shown, are guided, for example, from the card via guide rollers 41 and 42 to openings in the coiling head 13 and then to the turntable 14 , which rotates within the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com