Lubrication of parison moulds in a method for producing hollow glass products

A production method and mold technology, applied in glass blowing molding machines, blowing-blowing glass molding machines, glass production, etc., can solve the problems of reduced production time, loss of method output, and impact on the service life of molds, so as to save time, Effect of eliminating yield loss and optimizing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

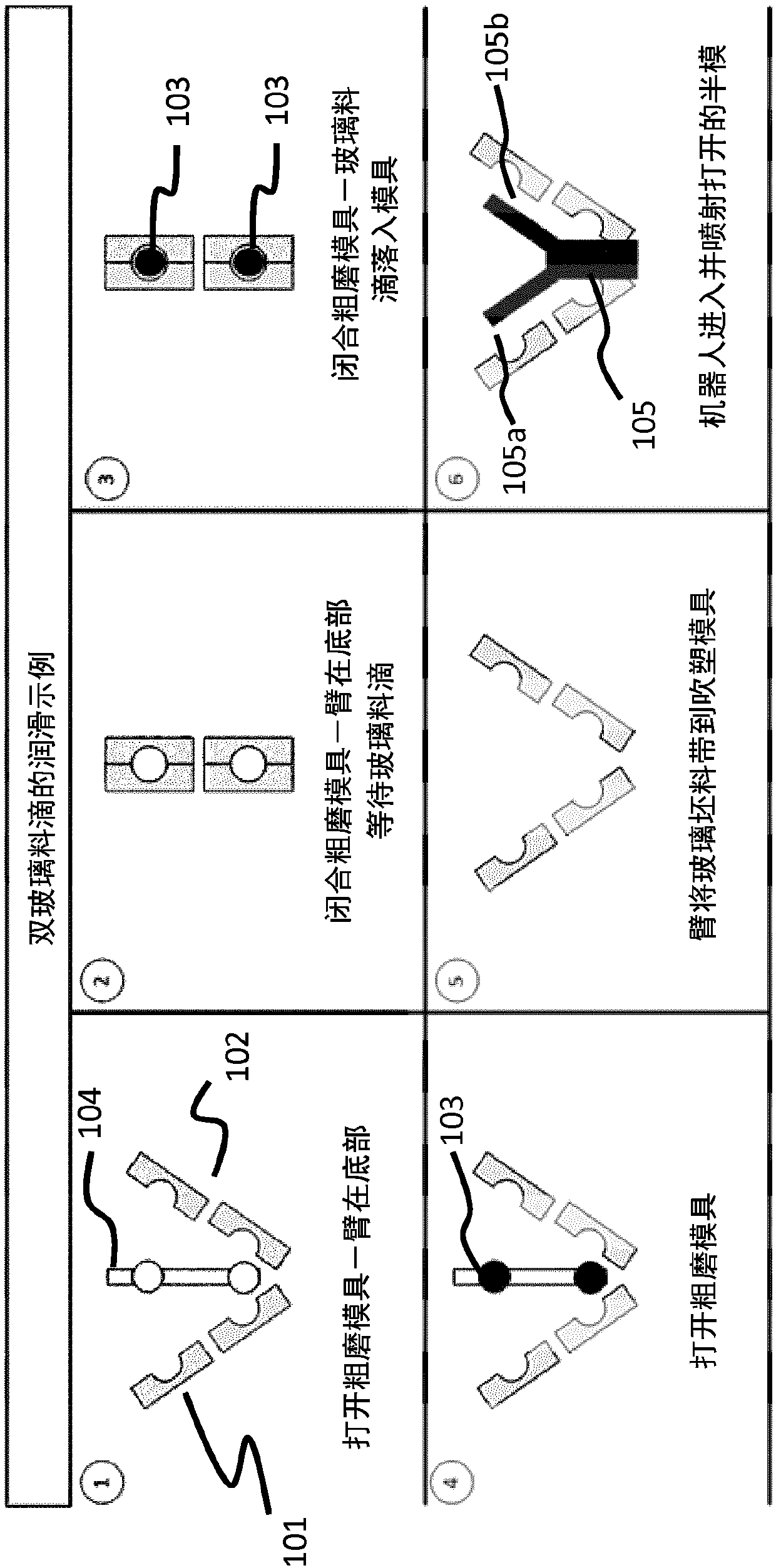

[0068] therefore, figure 1 Lubrication performed by the pressure blowing or blowing production method according to the invention is shown. The parison mold comprises two half-molds 101 , 102 with a double part closed at each production cycle, two glass gobs 103 loaded into the parison mold by gravity. After the two halves 101 , 102 of the parison mold are opened, a transfer arm 104 is used to transfer the gob 103 from the parison mold to the blow mould. The transfer arm 104 is able to perform a bi-directional movement between the parison mold and the blow mold by passing between the two halves 101, 102 of the parison mold, in order to transfer the preformed gob 103 from the parison mold to the blow mold. plastic mold.

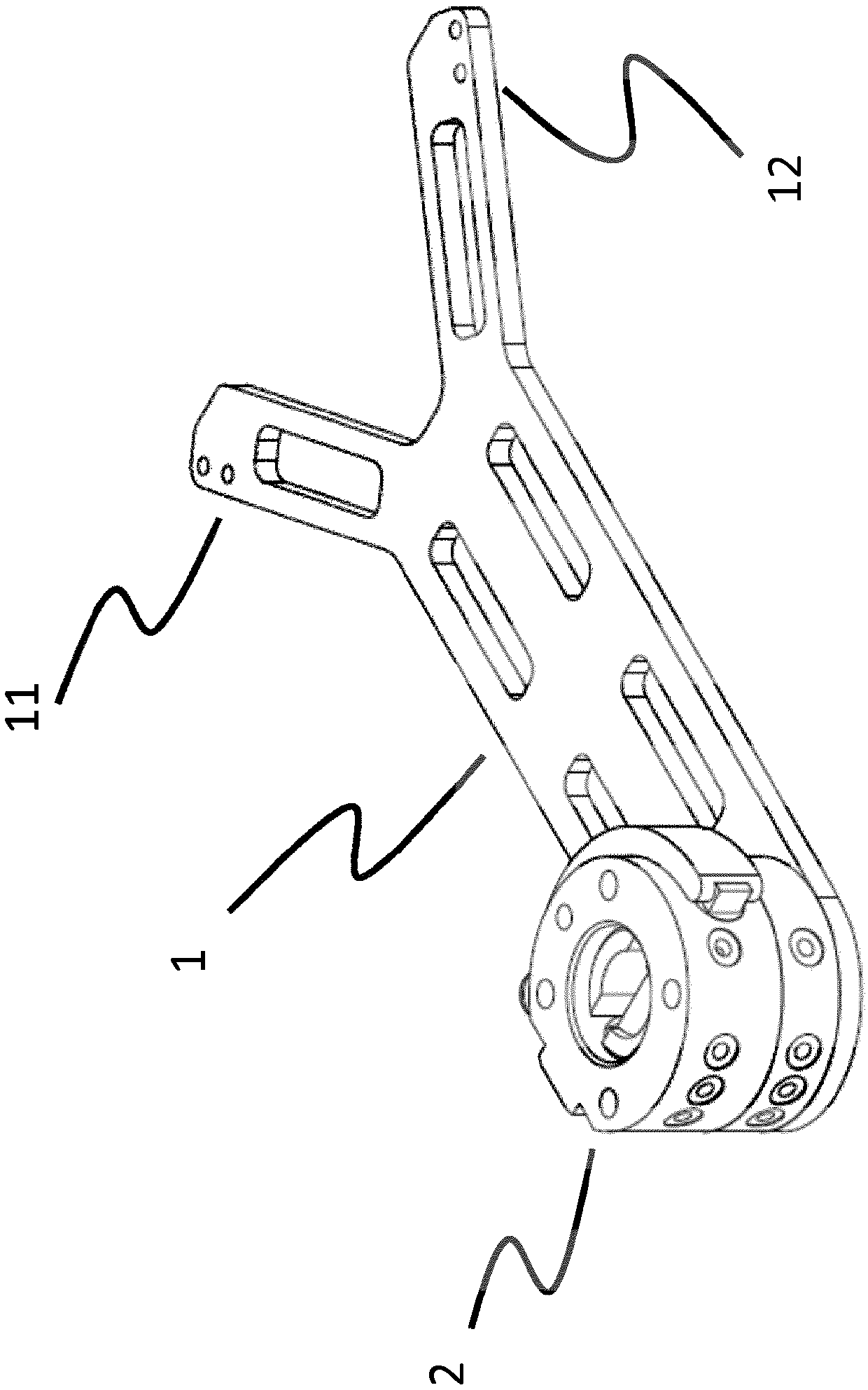

[0069] The method includes lubrication of the parison mold including spraying by nozzles 105a, 105b carried by a Y-arm 105 of a mobile robot moving along the parison mold side of the I.S. machine. The mobile robot is configured to:

[0070] (i) bringing sai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap