Enzyme preparation for degumming fresh ramie and preparation method thereof and method for degumming fresh ramie

A degumming method and enzyme preparation technology are applied in the chemical post-treatment of fibers, biochemical fiber treatment, plant raw materials, etc., which can solve the problems of low degumming quality, elevated COD, and harsh biological bacteria culture conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation of the fresh ramie hemp and the enzyme soaking step of the fresh ramie hemp of the present invention are preferably carried out in the ramie farmland, which reduces factory land and personnel allocation, which can expand the factory scale and reduce costs.

[0043] The invention provides an enzyme preparation for fresh ramie degumming, comprising: alkaline pectinase with an enzyme activity of 50U / mL-5000U / mL, neutral xylanase with an enzyme activity of 500U / mL-2000U / mL, Glucanase with enzyme activity of 4000U / mL-50000U / mL, mannanase with enzyme activity of 600U / mL-50000U / mL, surfactant and chelating agent. Wherein alkaline pectinase belongs to a kind of pectinase, also has a kind of acid pectinase in addition, because the enzyme preparation provided by the present invention is to act on ramie fresh hemp, and water content is big in ramie fresh hemp, if use acid fruit Gelase, it must be hydrolyzed and cause enzyme preparation catalytic degumming effect an...

Embodiment 1

[0053] Preparation of enzyme preparation:

[0054] Add 5mL of polyoxyethylene lauryl ether and 5mL of chelating agent into 1000mL of water at a temperature of 40°C, stir evenly, and obtain the first mixed solution after polyoxyethylene lauryl ether and the chelating agent are completely dissolved. Neutral xylanase, dextranase, and mannanase were added to the first mixed solution, and the enzyme activity was adjusted as follows: alkaline pectinase: 300U / ml; neutral xylanase: 1000U / ml; glucanase: 1000U / ml; Carbohydrase: 8000U / ml; Mannanase: 1000U / ml. Enzyme preparation for fresh hemp degumming was obtained.

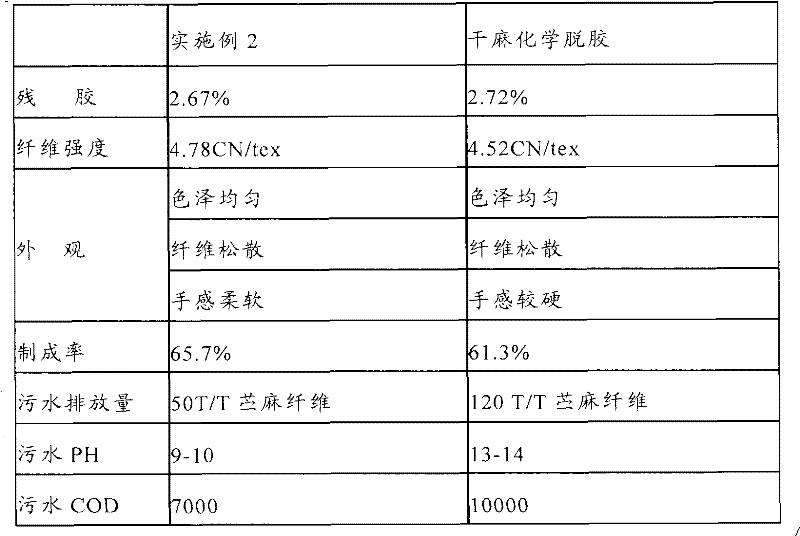

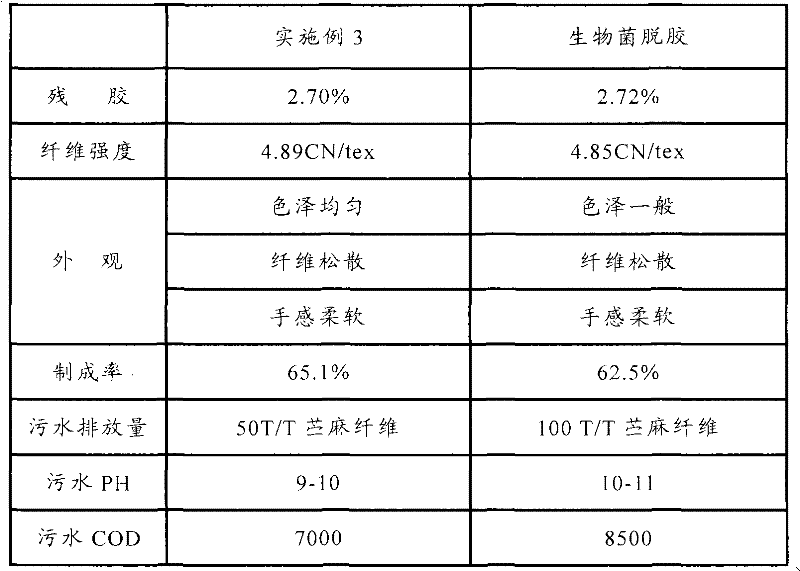

Embodiment 2

[0056] The origin of ramie: the efficiency of peeling hemp in Yuanjiang, Hunan; 265 kilograms of fresh hemp per day (equivalent to 100 kilograms of dry hemp)

[0057] After mechanical harvesting of fresh hemp, mechanical peeling and degreening, to obtain ramie fresh hemp, the prepared ramie fresh hemp is soaked in the container containing the enzyme preparation prepared in Example 1, and the enzyme soaking operation is carried out. The enzyme soaking temperature is 35°C The enzyme soaking time is 28h; the pH value is 8.5; the enzyme dosage is preferably 2.5% in the total weight percentage of fresh ramie. After the enzyme soaking operation is finished, the fresh hemp of ramie is taken out and placed on the hemp copying machine for pre-printing hemp operation. Pre-copy hemp 2 circles.

[0058] After the pre-coiling operation is finished, the ramie fresh hemp after the pre-coiling is packed into cages, 1200kg per cage, and then placed in the boiling and bleaching tank for high-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com