Method and device for producing an angular contact roller bearing

A roller bearing and angular contact technology, which is used in the field of manufacturing, especially single-row angular contact roller bearings, can solve the problems of loose rib gaskets, bearing failures, and adverse effects on the manufacturing cost of angular contact roller bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

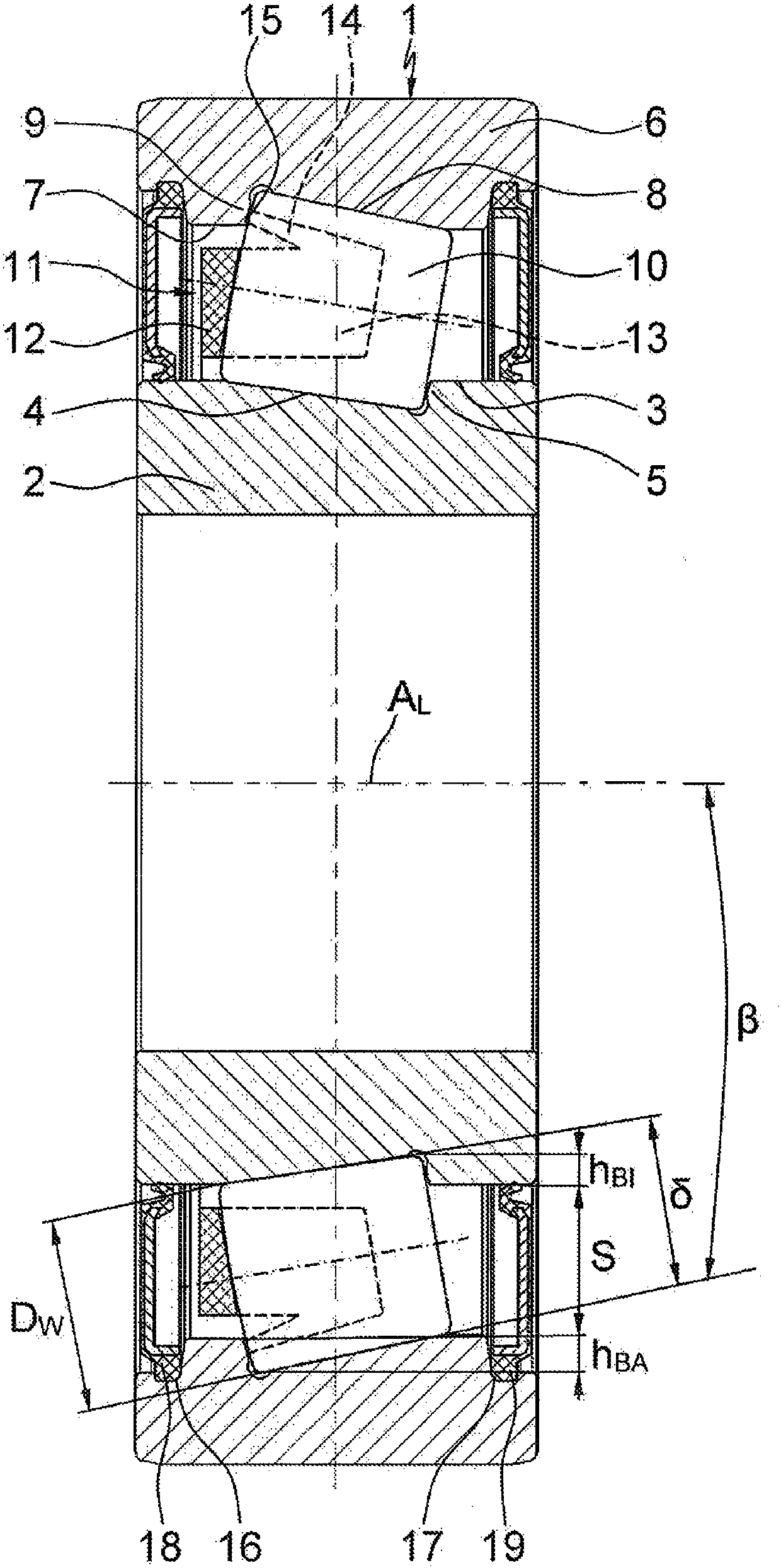

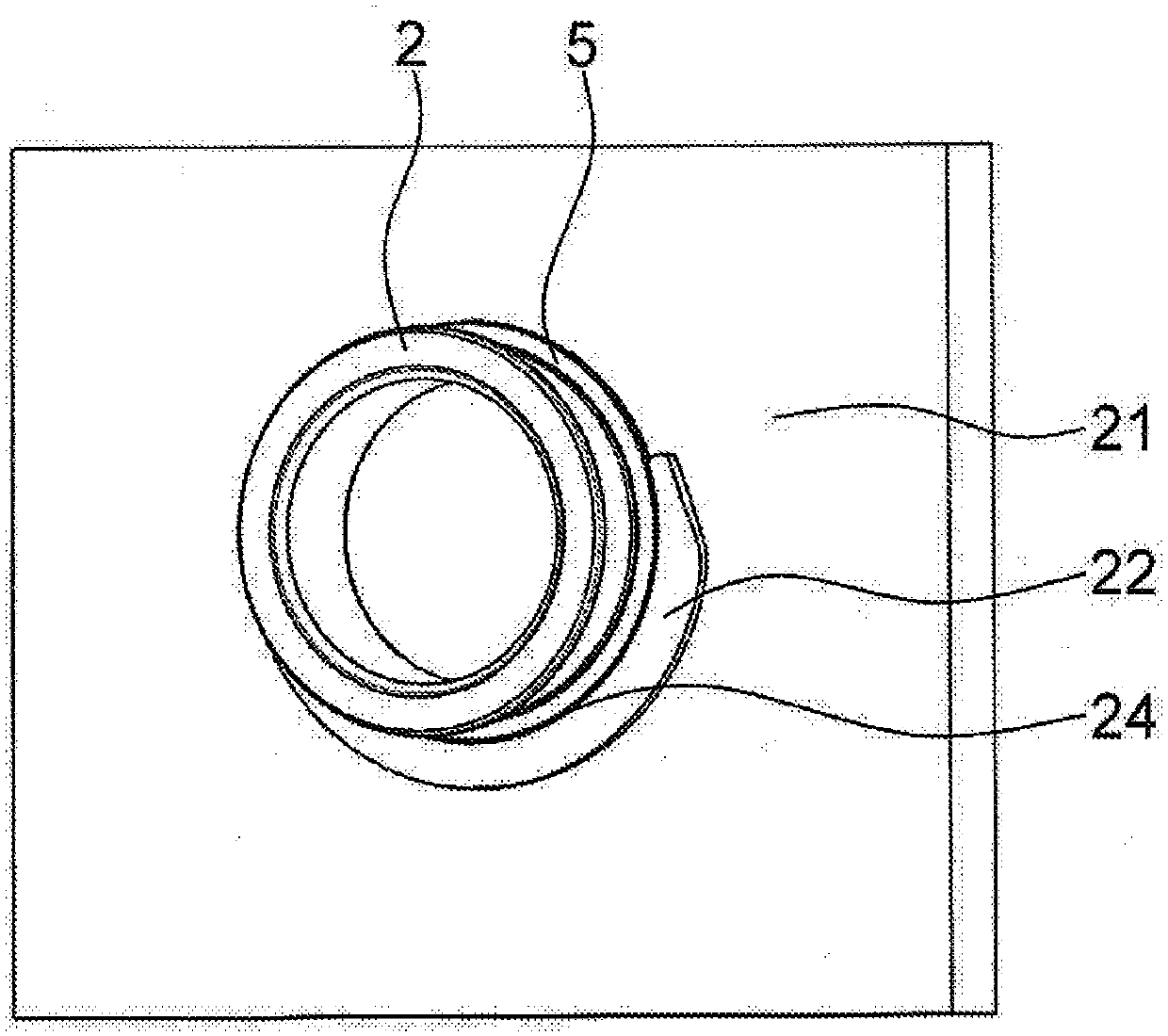

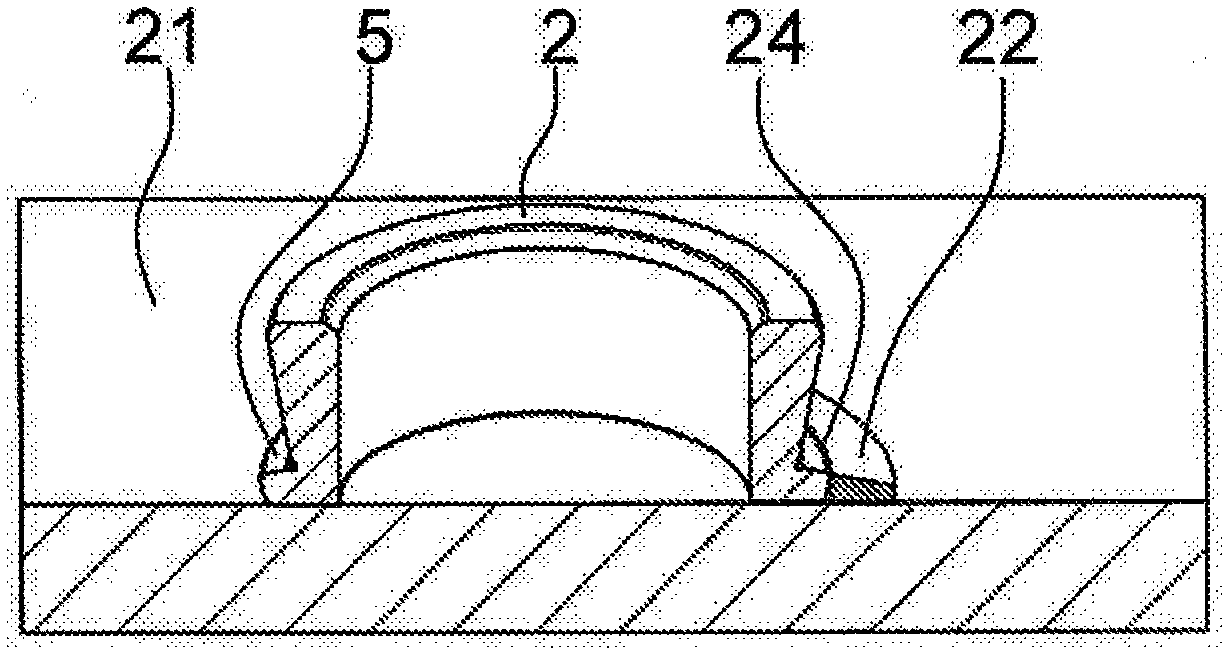

[0040] figure 1 shows a cross-section through a single-row angular contact roller bearing 1 , which is suitable, for example, as an alternative to the hitherto used deep groove ball bearings for supporting crankshafts in internal combustion engines of motor vehicles. It can be clearly seen that the angular contact roller bearing 1 is formed by an inner bearing ring 2 and an outer bearing ring 6 , the inner bearing ring having a bearing on its outer circumferential side 3 relative to the axis of rotation A of the bearing. L The obliquely arranged inner raceway 4 , which is delimited at its smallest diameter by ribs 5 , the outer bearing ring has on its inner circumferential side 7 also relative to the bearing axis of rotation A L The obliquely arranged outer raceway 8 is delimited at its largest diameter by ribs 9 . Between the bearing rings 2, 6 are also arranged a plurality of roller rolling bodies 10 rolling on the raceways 4, 8 of these bearing rings, and the roller rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com