Base strip for connection with at least one plug-in connector part

A technology for connectors and substrates, applied in two-part connection devices, parts of connection devices, devices for preventing wrong connections, etc., can solve problems such as fracture, increase the difficulty of base strips, and reduce the firmness of contact elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

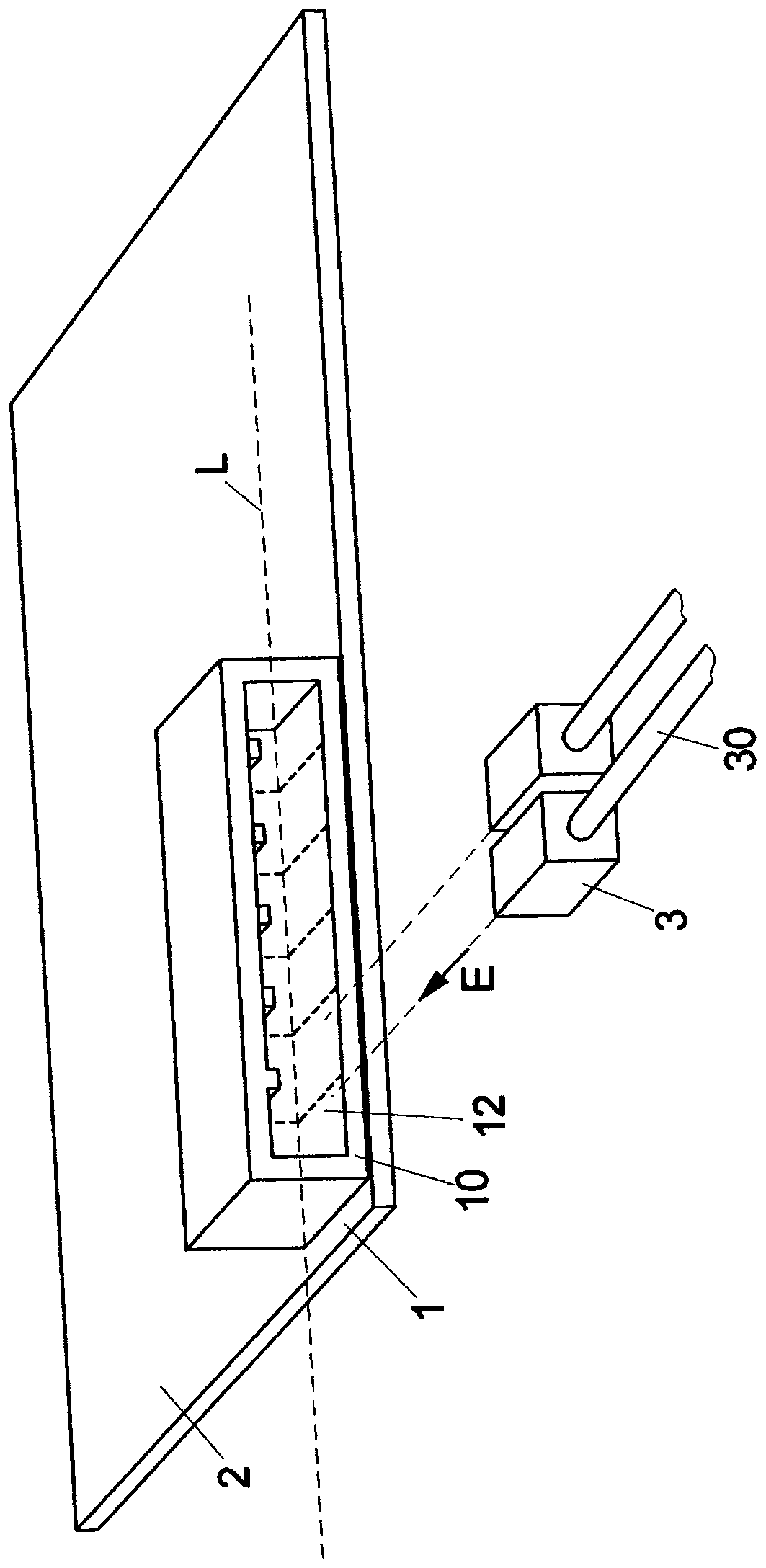

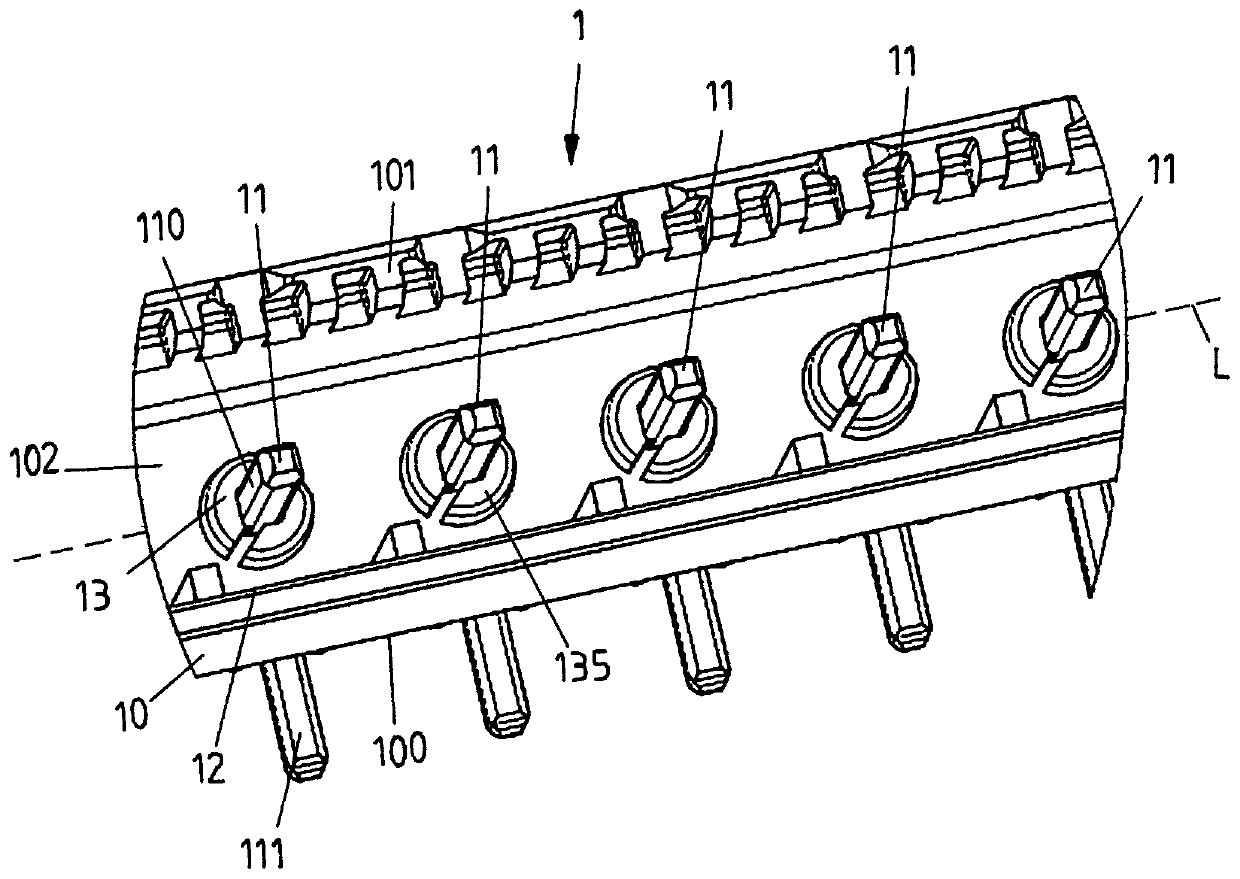

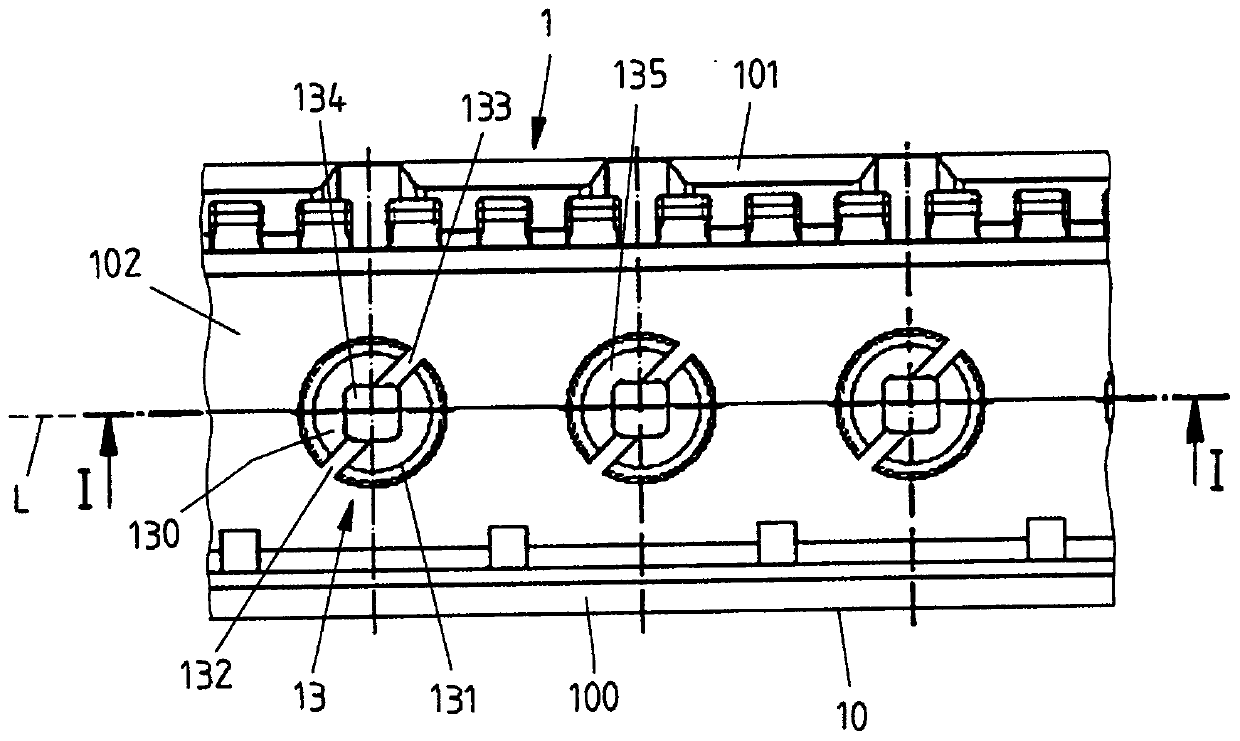

[0030] figure 1 It is a schematic diagram of a printed circuit board 2 on which a base strip 1 is arranged. The base strip 1 extends longitudinally along a longitudinal axis L and has a housing 10 realizing several sockets 12 for the insertion of plug-in connector parts 3 in the form of plugs.

[0031] The printed circuit board 2 can, for example, be made in a known manner from an electrically insulating material and have a pattern of conductive paths on one or both sides. Electrical and / or electronic components can be arranged on the printed circuit board, which are connected by conductive paths in order to form an electrical switching circuit.

[0032] The base strip 1 has several contact elements corresponding to the sockets 12 . By inserting the plug-in connector part 3 into the socket 12 in the plug-in direction E, the plug-in connector part 3 is brought into electrical contact with the contact element corresponding to this socket 12 and the connection to the plug-in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com