Portable steel bar bending machine for construction site

A portable, bending machine technology, applied in the field of steel processing equipment, can solve the problems of difficult operation, high price, insufficient storage of bending steel bars, etc., and achieve the effects of convenient operation, good bending, and easy popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

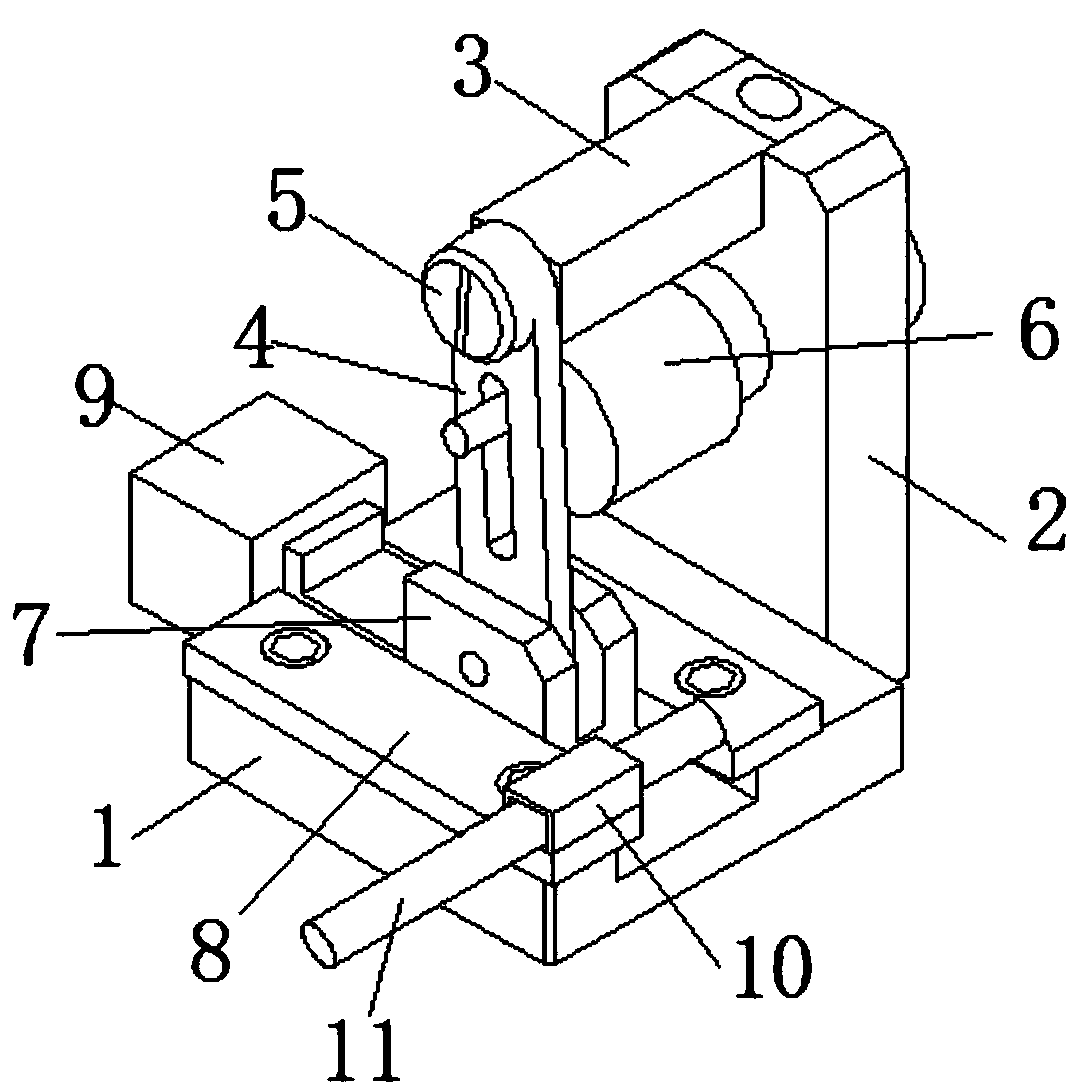

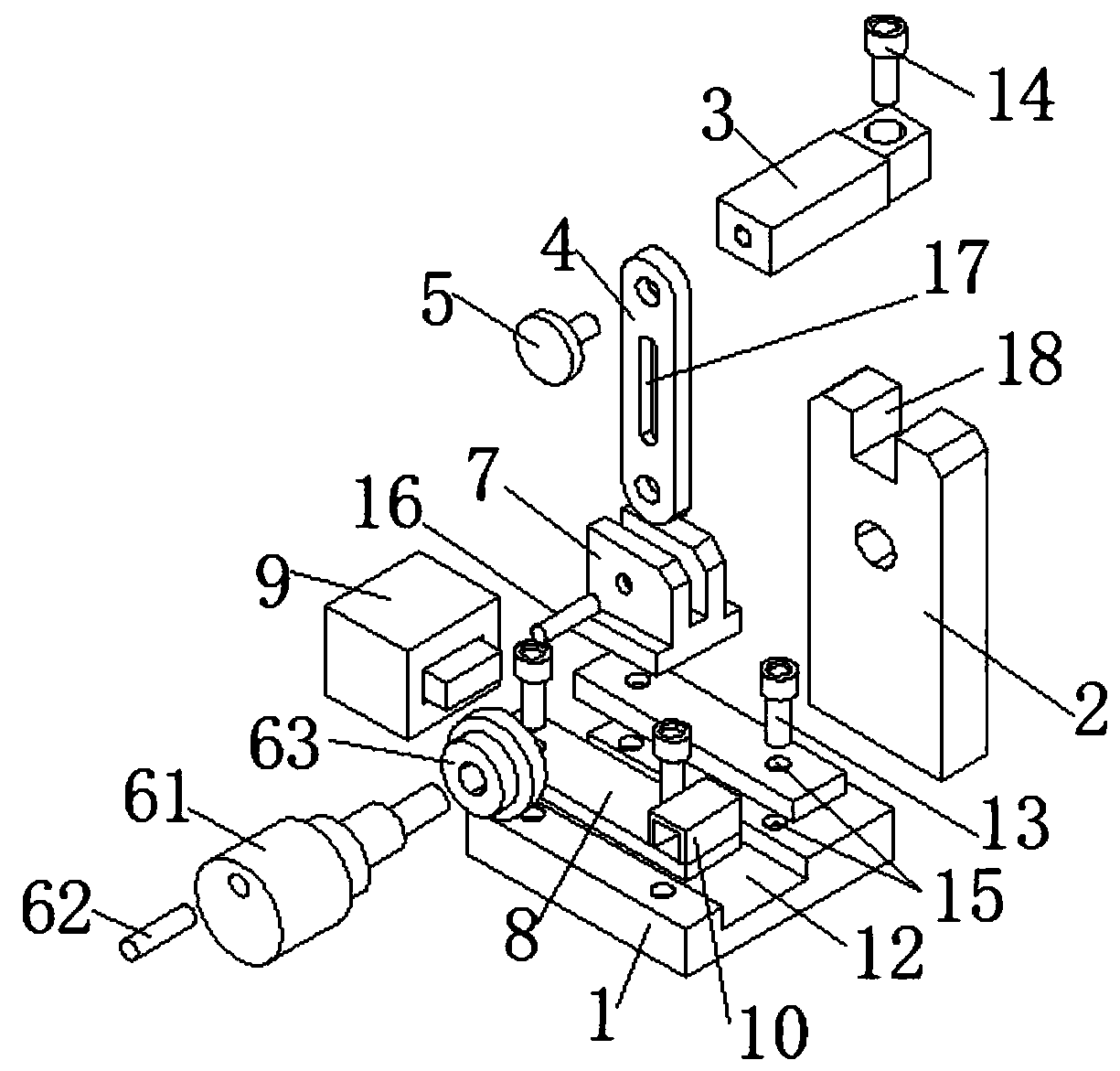

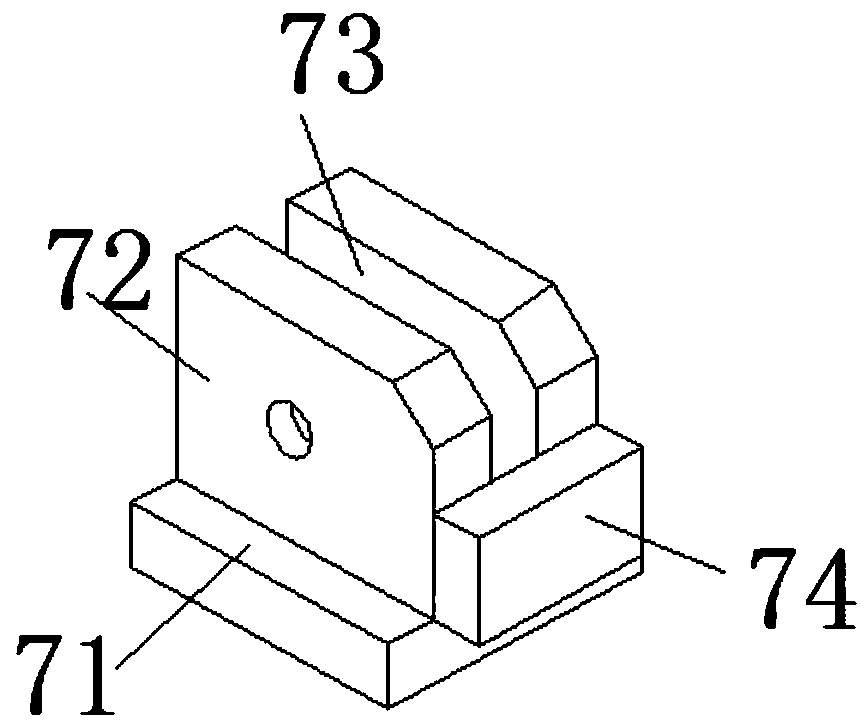

[0020] see figure 1 with figure 2 , the present invention provides the following embodiments: a portable steel bar bending machine for a construction site, including an underframe 1, a support platform 2, a hydraulic propulsion device 9 and a runner 6, and one side of the underframe 1 is fixedly provided with a support platform 2. The top of the supporting platform 2 is fixedly provided with a main beam 3 perpendicular to it, the other end of the main beam 3 is connected with one end of the rotating plate 4 through the rotating pin 5, and the other end of the rotating plate 4 is connected with the pusher arranged on the bottom frame 1. The table 7 is hingedly connected, the inside of the rotating plate 4 is connected with the runner 6 fixed on the support table 2, and a pressing plate 8 is fixed on the upper surface of the chassis 1, and the pressing plate 8 limits the pushing platform 7 to the chassis 1. One end surface of the push platform 7 is in contact with the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com