Drilling machining positioning component for engine crankshaft bearing cover

A technology for positioning components and crankshaft bearings, used in metal processing machinery parts, positioning devices, metal processing and other directions, can solve the problems of economic loss, inconvenient identification, quality accidents, etc., and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings;

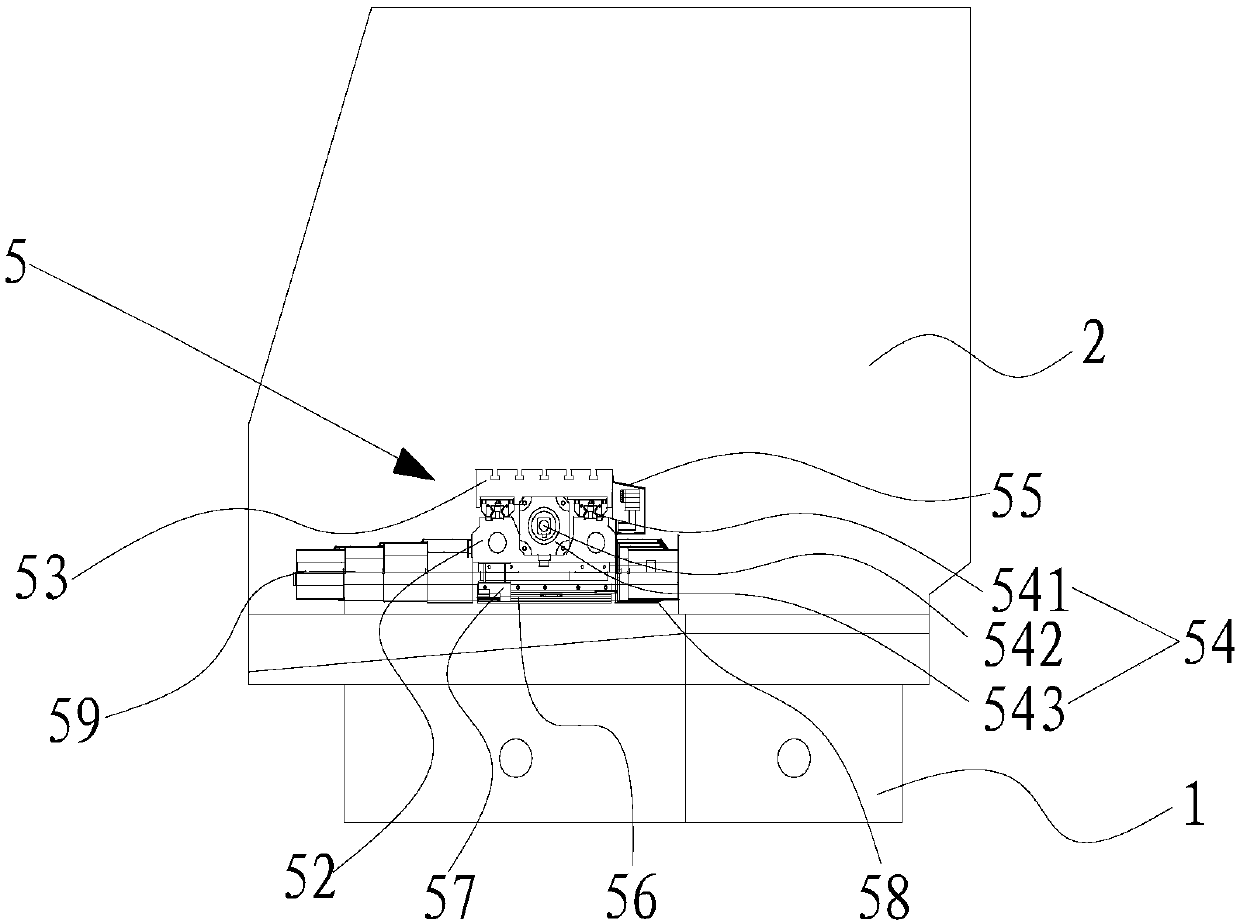

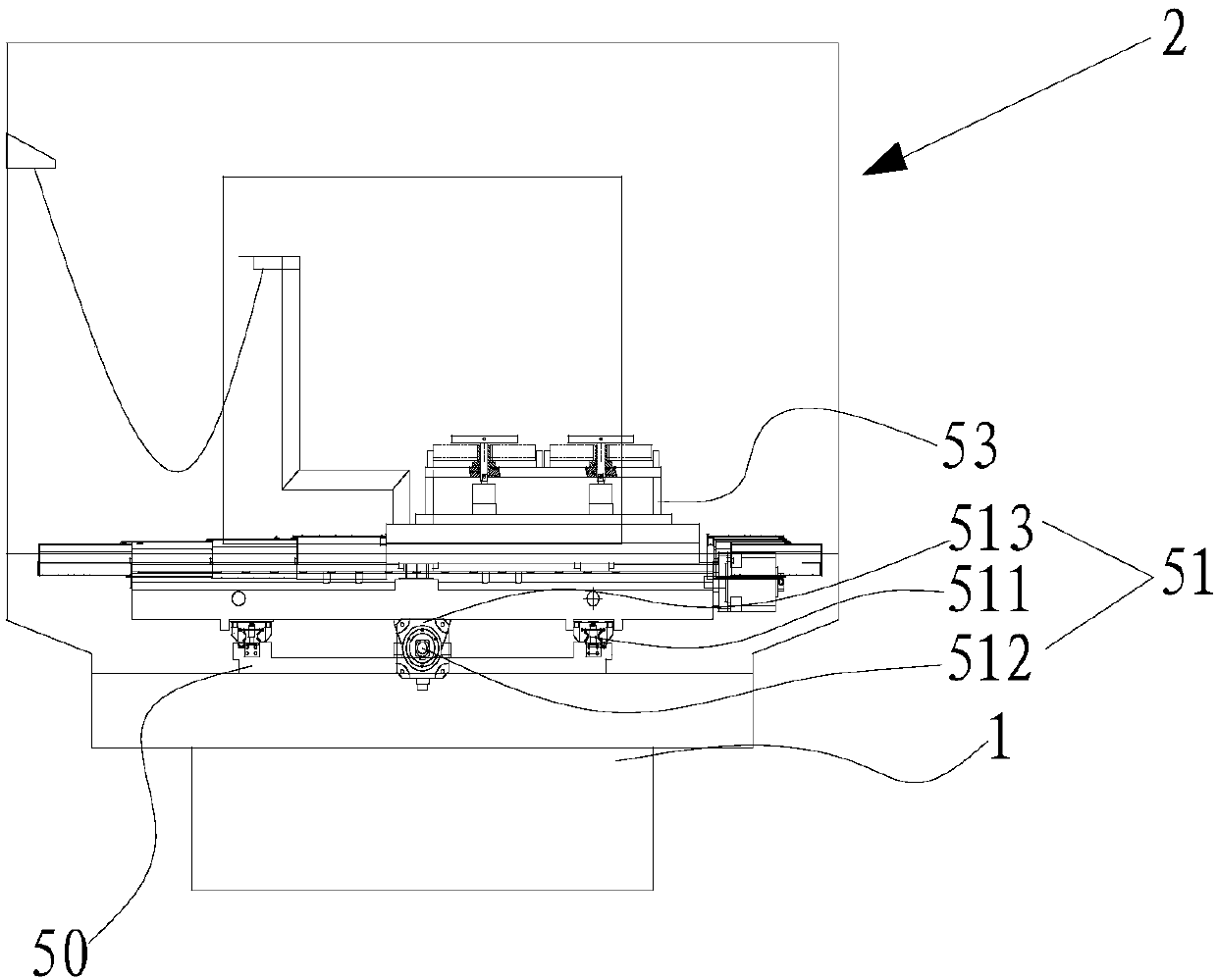

[0012] Such as figure 1 and figure 2 The shown engine crankshaft bearing cover drilling and positioning assembly 5 includes multiple supporting bases 50 fixed on the upper surface of the base 1 and arranged at intervals, a material receiving base 52 slidably installed on the supporting bases 50 , a slidable The bearing cover clamp 53 installed on the material receiving base 52, the material guide plate 55 installed on the side of the bearing cover clamp 53 (it can correspond to the support frame 2), the limit position fixed on the outer surface of the support bottom column 50 Slide rail 56 and be slidably installed on the limit slide rail 56 and the upper end extends to the support slide block 57 that is fixed on the bottom of material receiving base 52 (utilizing the cooperation of support slide block 57 and limit slide rail 56 can hold ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com