A kind of heat-absorbing material of nickel-containing alloy hollow sphere and its preparation method

An endothermic material and hollow sphere technology, applied in the field of solar energy absorption, can solve the problems of low thermal efficiency of solar collectors, poor weather resistance of coatings, premature powdering, etc., and achieve low emissivity, low cost, and enhanced bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

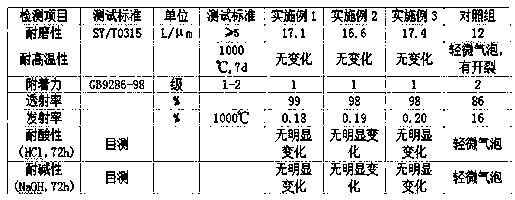

Examples

Embodiment 1

[0018] A heat-absorbing material of a nickel-containing alloy hollow sphere and a preparation method thereof. The heat-absorbing material is made of the following raw materials in parts by weight:

[0019] 25 parts of nickel alloy hollow spheres, 15 parts of silicone resin, 35 parts of epoxy resin, 10 parts of ethanol, 3 parts of silane coupling agent, 2 parts of silica sol, 5 parts of nano-alumina powder, 5 parts of nano-iron sesquioxide powder parts and 15 parts of deionized water.

[0020] The nickel alloy hollow sphere is prepared from nickel salt, sodium hydroxide, reducing agent and additives. The nickel salt is nickel sulfate, nickel nitrate, nickel acetate or nickel chloride; the reducing agent is hypophosphite, borohydride or hydrazine hydrate; the additive is lactic acid, citric acid, succinic acid or adipic acid. The diameter of the nickel alloy hollow sphere is less than 1 μm.

[0021] The preparation method includes the following:

[0022] (1) Dissolve epoxy re...

Embodiment 2

[0026] A heat-absorbing material of a nickel-containing alloy hollow sphere and a preparation method thereof. The heat-absorbing material is made of the following raw materials in parts by weight:

[0027] 20 parts of nickel alloy hollow spheres, 10 parts of silicone resin, 10 parts of epoxy resin, 1 part of ethanol, 2 parts of silane coupling agent, 1 part of silica sol, 1 part of nano-alumina powder, 1 part of nano-iron sesquioxide powder parts and 20 parts of deionized water.

[0028] The nickel alloy hollow sphere is prepared from nickel salt, sodium hydroxide, reducing agent and additives. The nickel salt is nickel sulfate, nickel nitrate, nickel acetate or nickel chloride; the reducing agent is hypophosphite, borohydride or hydrazine hydrate; the additive is lactic acid, citric acid, succinic acid or adipic acid. The diameter of the nickel alloy hollow sphere is less than 1 μm.

[0029] The preparation method includes the following:

[0030] (1) Dissolve epoxy resin i...

Embodiment 3

[0034] A heat-absorbing material of a nickel-containing alloy hollow sphere and a preparation method thereof. The heat-absorbing material is made of the following raw materials in parts by weight:

[0035] 30 parts of nickel alloy hollow spheres, 20 parts of silicone resin, 60 parts of epoxy resin, 20 parts of ethanol, 4 parts of silane coupling agent, 3 parts of silica sol, 10 parts of nano-alumina powder, 10 parts of nano-ferric oxide powder parts and 10 parts of deionized water.

[0036] The nickel alloy hollow sphere is prepared from nickel salt, sodium hydroxide, reducing agent and additives. The nickel salt is nickel sulfate, nickel nitrate, nickel acetate or nickel chloride; the reducing agent is hypophosphite, borohydride or hydrazine hydrate; the additive is lactic acid, citric acid, succinic acid or adipic acid. The diameter of the nickel alloy hollow sphere is less than 1 μm.

[0037] The preparation method includes the following:

[0038] (1) Dissolve epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com