Supporting method used for multi-branch beam-column body of Chinese style building

A support method and technology for road beams and columns, which are applied in construction, building structure, and building material processing, etc., can solve problems such as inconvenience in engineering construction, and achieve the effect of saving construction procedures and reliable support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

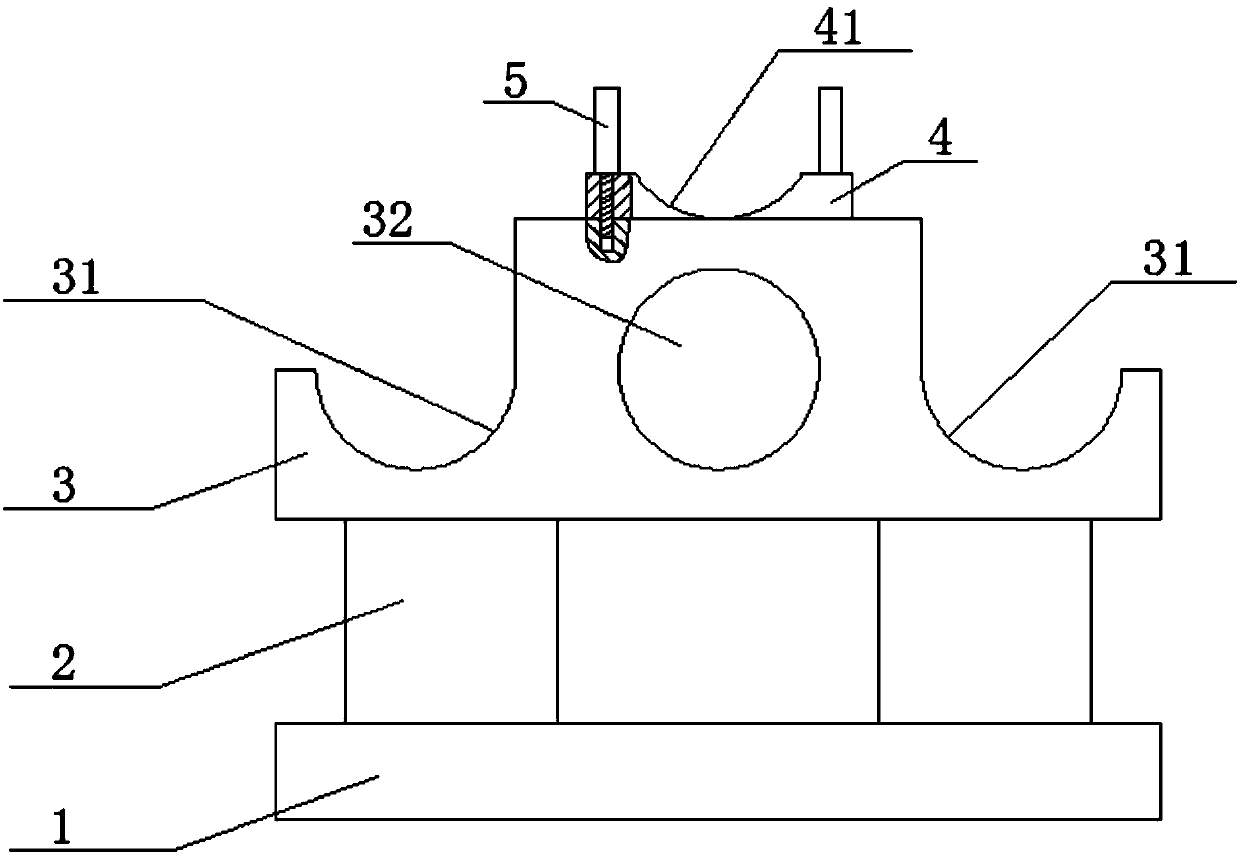

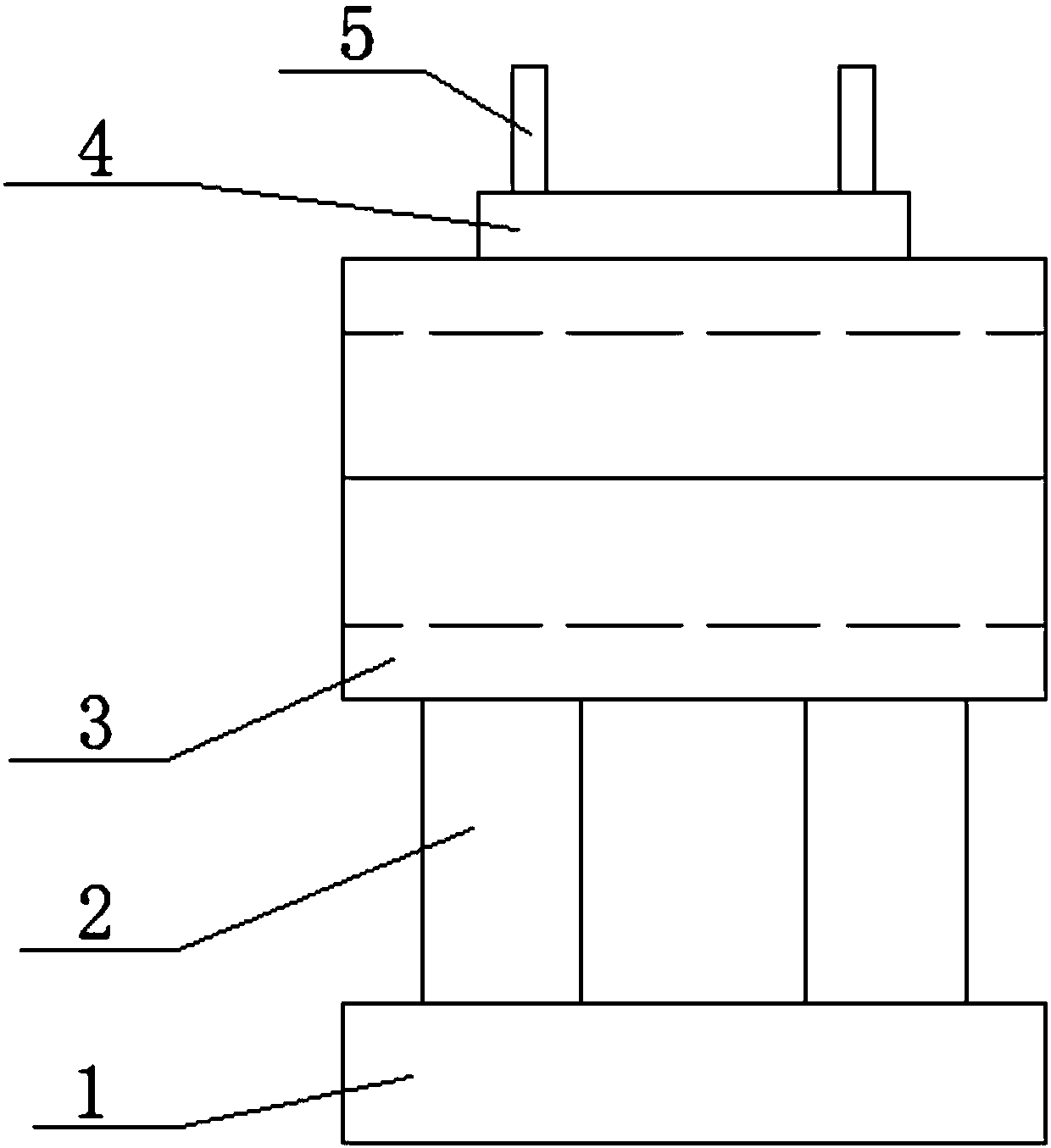

[0026] Such as figure 1 and figure 2 As shown, for the method of beam-column support for multi-branch roads in Chinese architecture, step 1) set the base 1, and use the base 1 to connect the support frame 3 for supporting the beam-column body through the vertical cross support column 2;

[0027] Step 2) Set the support frame 3 as an inverted T-shaped structure, connect the vertical cross support column 2 to the horizontal part of the support frame 3, and open a through hole 32 on the vertical part of the support frame 3,

[0028] Step 3) Semicircular grooves 31 are respectively provided on both sides of the horizontal part of the support frame 3, a support pad 4 is provided on the upper surface of the vertical part of the support frame 3, and an arc-shaped recess is provided on the support pad 4 upper surface. Slot 41.

[0029] According to the present invention, through the through holes 32 on the vertical part of the support frame 3, the semicircular grooves 31 on both si...

Embodiment 2

[0031] This embodiment is a further improvement made on the basis of the above-mentioned embodiment 1, as figure 1 and figure 2 As shown, in this embodiment, the left and right sides of the support block 4 are provided with limit rods 5 for fixing the beam and column, so as to prevent the beam and column from slipping and ensure the reliable support of the beam and column. The lower end of the limit rod 5 is provided with an external thread, and the connection between the support pad 4 and the limit rod 5 is provided with a threaded hole, and the threaded hole cooperates with the external thread on the limit rod 5, and the upper surface of the vertical part of the support frame 3 is in contact with the screw thread. A blind hole is provided at the position corresponding to the hole, and an internal thread cooperating with the external thread on the limit rod 5 is arranged in the blind hole. In this way, there is no need to separately design a connecting piece for connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com