Tunneling, anchoring and protecting integrated tunneling-anchoring-protecting machine

An integrated technology of digging, bolting and protecting, which is applied in the field of bolting and protecting machines, can solve problems such as low efficiency, high labor intensity of manual bolting, and time waste, so as to improve safety, improve safety and convenience, and reduce work The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

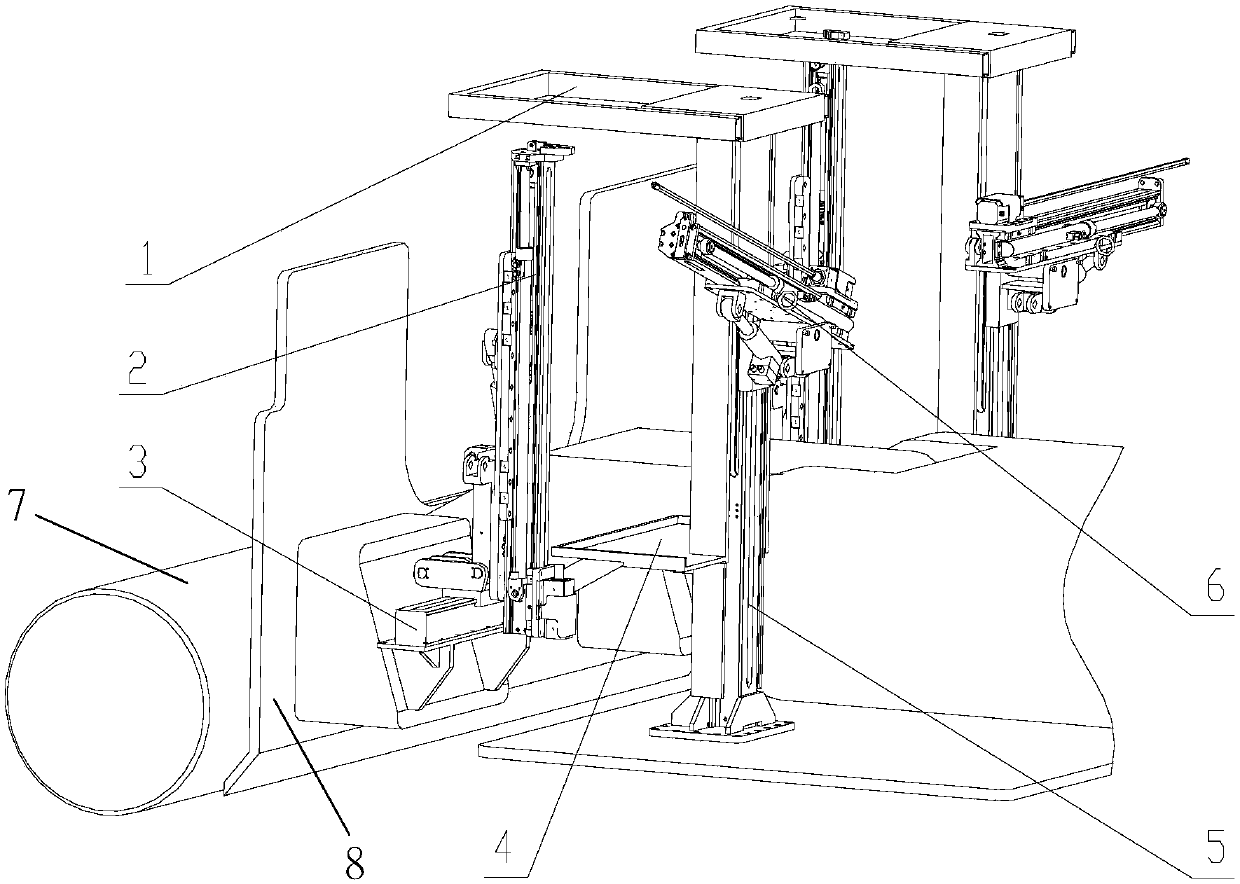

[0013] like figure 1 As shown, the present invention excavates, anchors, protects the integration of digging and anchoring and protecting the machine, mainly comprises: tunneling machine 7, top bolter 2, side side bolter 6, slideway device, temporary support mechanism 1, lifting operation Platform 4, etc., the specific structure is as follows:

[0014] The front row of the bolter protector adopts two top bolters 2 installed on the horizontal slideway device 3, and the topbolt machine 2 is leveled by the horizontal slideway device 3 fixed on the front vertical plate 8 of the roadheader 7. Move to complete the anchoring of the roof bolt; the back row of the bolter protector adopts two side bolters 6 installed on the vertical slideway device 5, and the sideside bolter 6 passes through the vertical slideway device 5 up and down Move to complete the anchor installation of the side anchor rod; the temporary support mechanism 1 and the lifting operation platform 4 adopt an integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com