A kind of equipment for stainless steel processing

A stainless steel and equipment technology, applied in mechanical equipment, through components, threaded connections, etc., can solve problems such as endangering the safety of workers, poor sealing effect, nitrogen leakage, etc., to reduce equipment costs, improve sealing performance, and improve sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

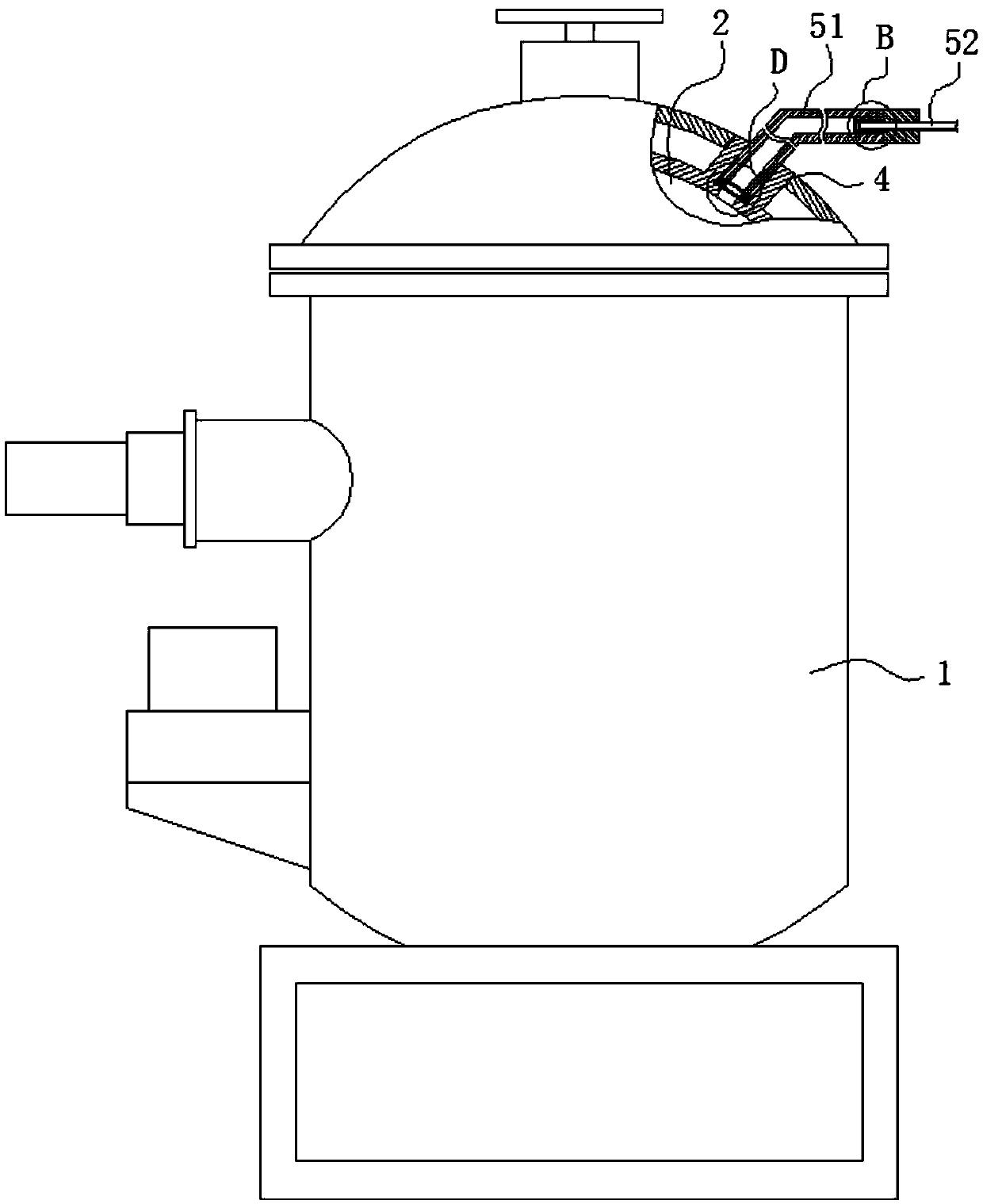

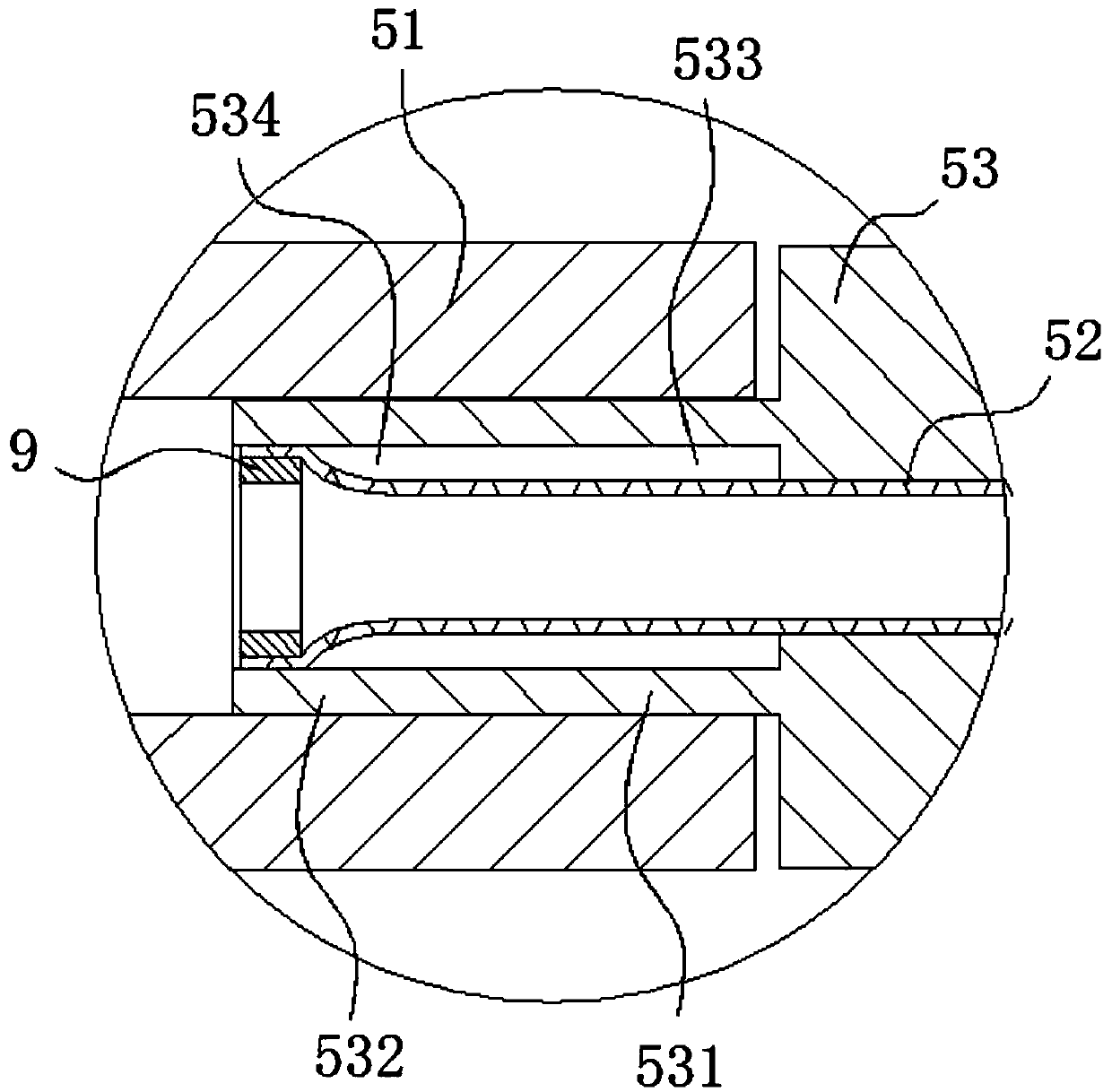

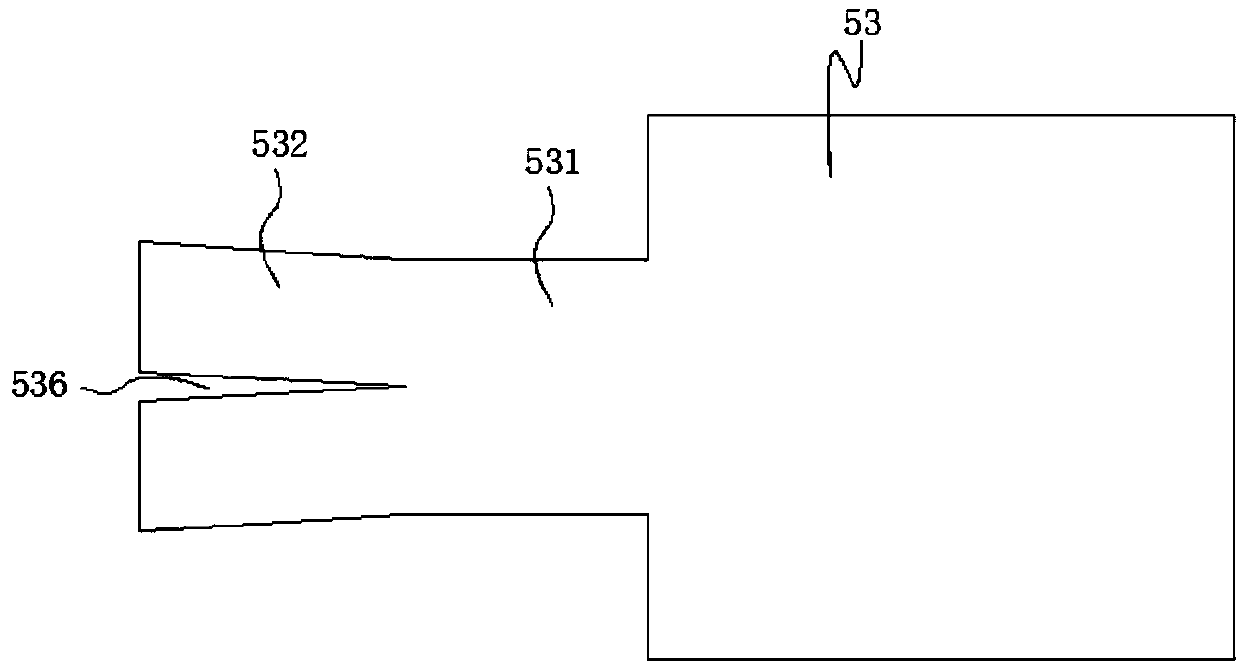

[0022] like Figure 1-5 Shown, a smelting equipment, including a furnace shell 1, a furnace 2, an air inlet 3 provided on the furnace 2, an opening 4 arranged on the furnace shell to match the air inlet, and an opening 4 matched with the air inlet The air intake pipe 5; the air intake portion 3 is formed by directly extending outward from the upper part of the furnace, the opening 4 is circular, and is opened on the upper part of the furnace shell, and the end of the air intake portion is located in the opening; The air inlet part 3 is provided with a cylindrical connection chamber, and the bottom of the connection chamber is provided with a circular air inlet 31, which communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com