Stoking machine

A technology of furnace smelting machine and walking mechanism, which is applied to furnaces, furnace components, descaling devices, etc., can solve the problems of small working range of smelting furnaces, and achieve the effect of increasing the working range and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

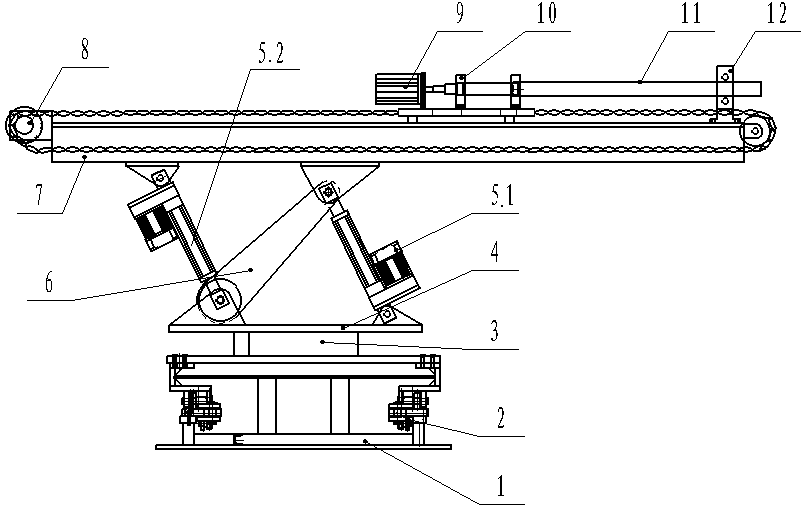

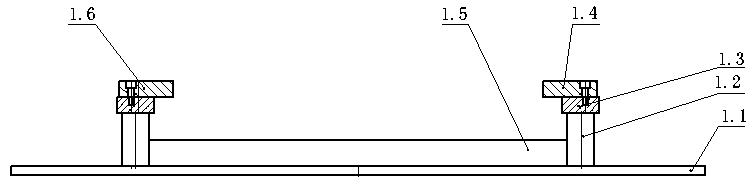

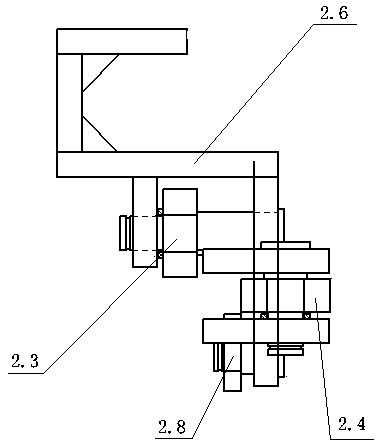

[0024] Such as figure 1 As shown, a furnace stamping machine includes a guide rail 1, a traveling mechanism 2, a turntable drive 3, a rotating platform 4, an electric push rod 5, a support arm 6, an upper workbench 7, a drill rod motor 9, a bearing seat 10, a drill rod 11 and the drill pipe support seat 12, the traveling mechanism 2 is arranged on the guide rail 1, the traveling mechanism 2 is provided with a rotating platform 4, the rotating platform 4 is controlled by the turntable drive 3, and the upper side of the rotating platform 4 is hinged with one end of the supporting arm 6, supporting The other end of the arm 6 is hinged with the bottom of the upper worktable 7, and the hinge of the support arm 6 and the rotating platform 4 is hinged with an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com