Integrated monitoring method and device for oil level and oil temperature of distribution transformer

A technology for distribution transformers and monitoring devices, applied in measurement devices, thermometers and instruments with physical/chemical changes, etc., can solve problems such as inability to monitor oil level, reliability of power supply and signal transmission, and complex electrical and mechanical structures. Achieve the effect of improving monitoring efficiency, solving the inconvenience of power supply and installation, and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, specific implementations thereof will be described in detail below in conjunction with the accompanying drawings.

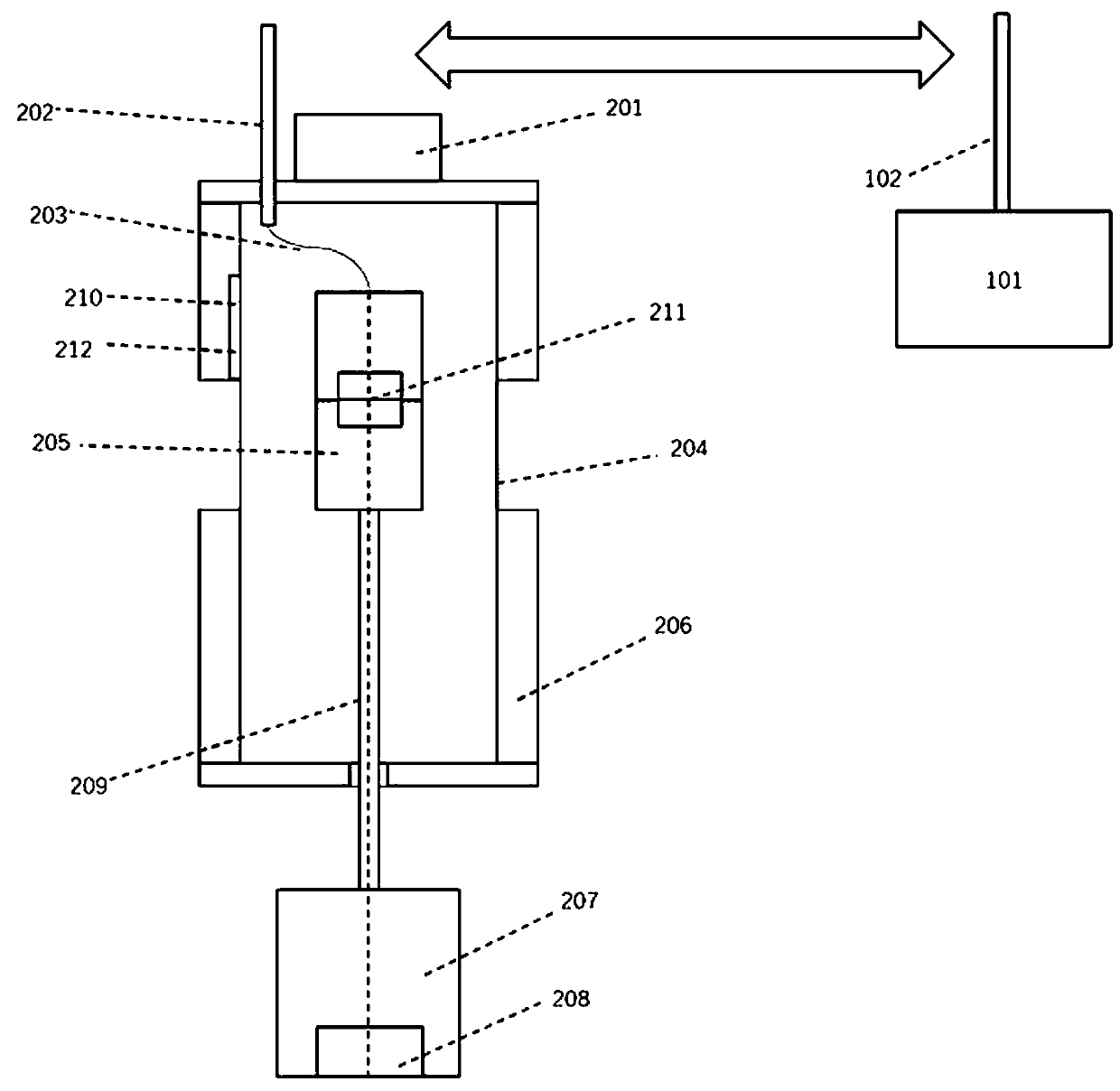

[0037] Such as figure 1 As shown, the present invention provides a monitoring device for distribution transformers, including: reader 101, reader antenna 102, pressure relief valve 201, sensor antenna 202, feeder 203, observation window 204, identification tube 205, housing 206 , floating piece 207, oil temperature sensor 208, connecting rod 209, ambient temperature sensor 210, magnetic body 211 and magnetic control switch 212.

[0038] Among them, the oil temperature sensor 208 is embedded in the lower part of the floating part 207 for measuring the oil temperature; the outer shell 206 is generally arranged on the tank cover of the transformer oil tank, and the floating part 207 is immersed in the transformer oil tank, and the oil temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com