Method for detecting carbon content of boiler slag

A detection method, boiler slag technology, applied in the detection field, can solve problems such as the impact of shooting environment, and achieve the effect of low acquisition conditions, less time consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

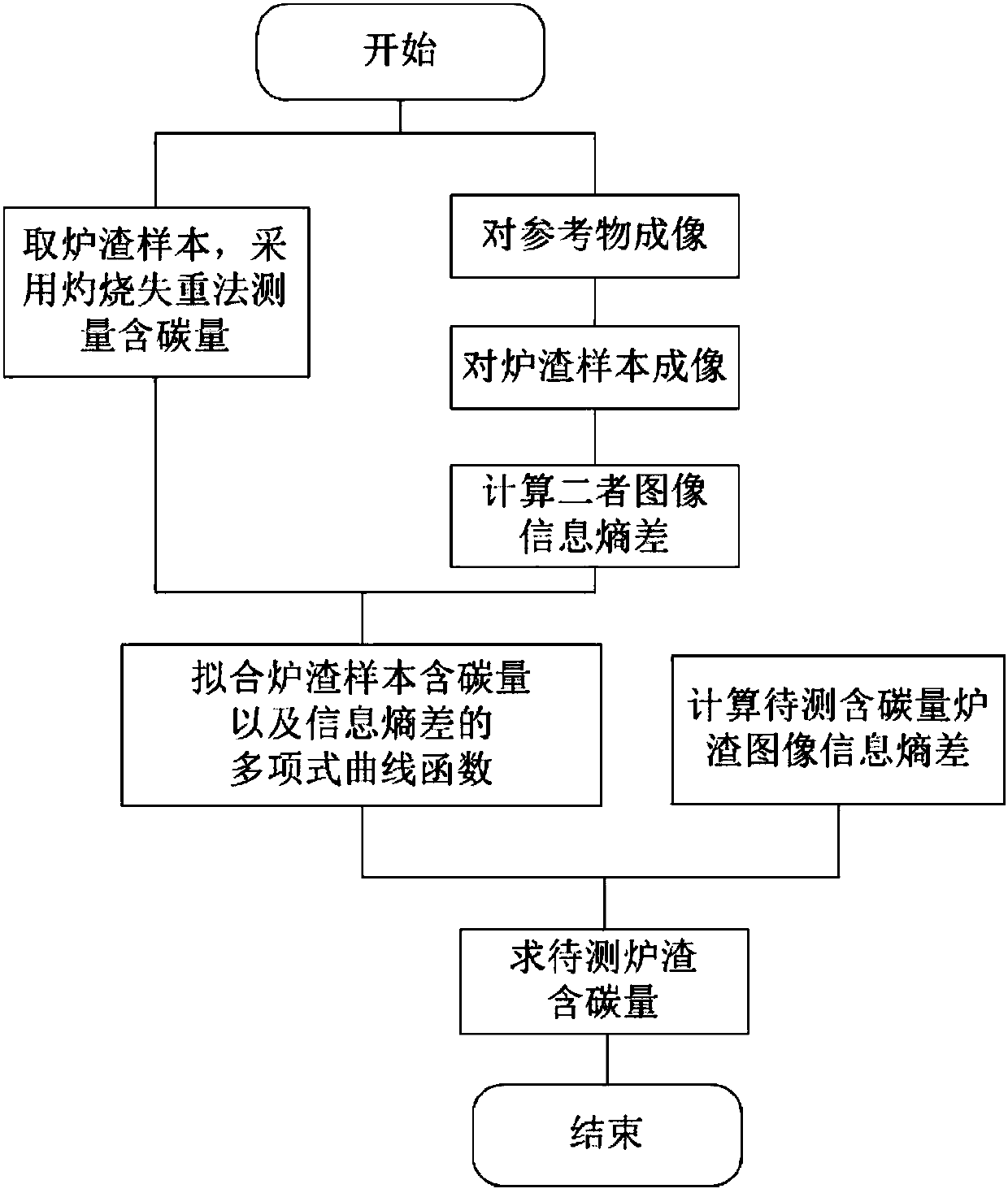

[0029] see figure 1 , figure 2 and image 3 , the present invention comprises the following steps:

[0030] 1) Randomly sample the slag after different combustion states. It is better to have a large number of samples to calculate the carbon content. It is required that the carbon content of these samples change evenly. Among them, the detection method of the carbon content of the slag sample is obtained by the accurate and reliable ignition weight loss method commonly used at present, referring to the relevant regulations of DL / T 567.6-1995 "Determination of fly ash and slag combustibles".

[0031] 2) Imaging the slag sample and the reference object to obtain the information entropy difference between the two, including the following steps:

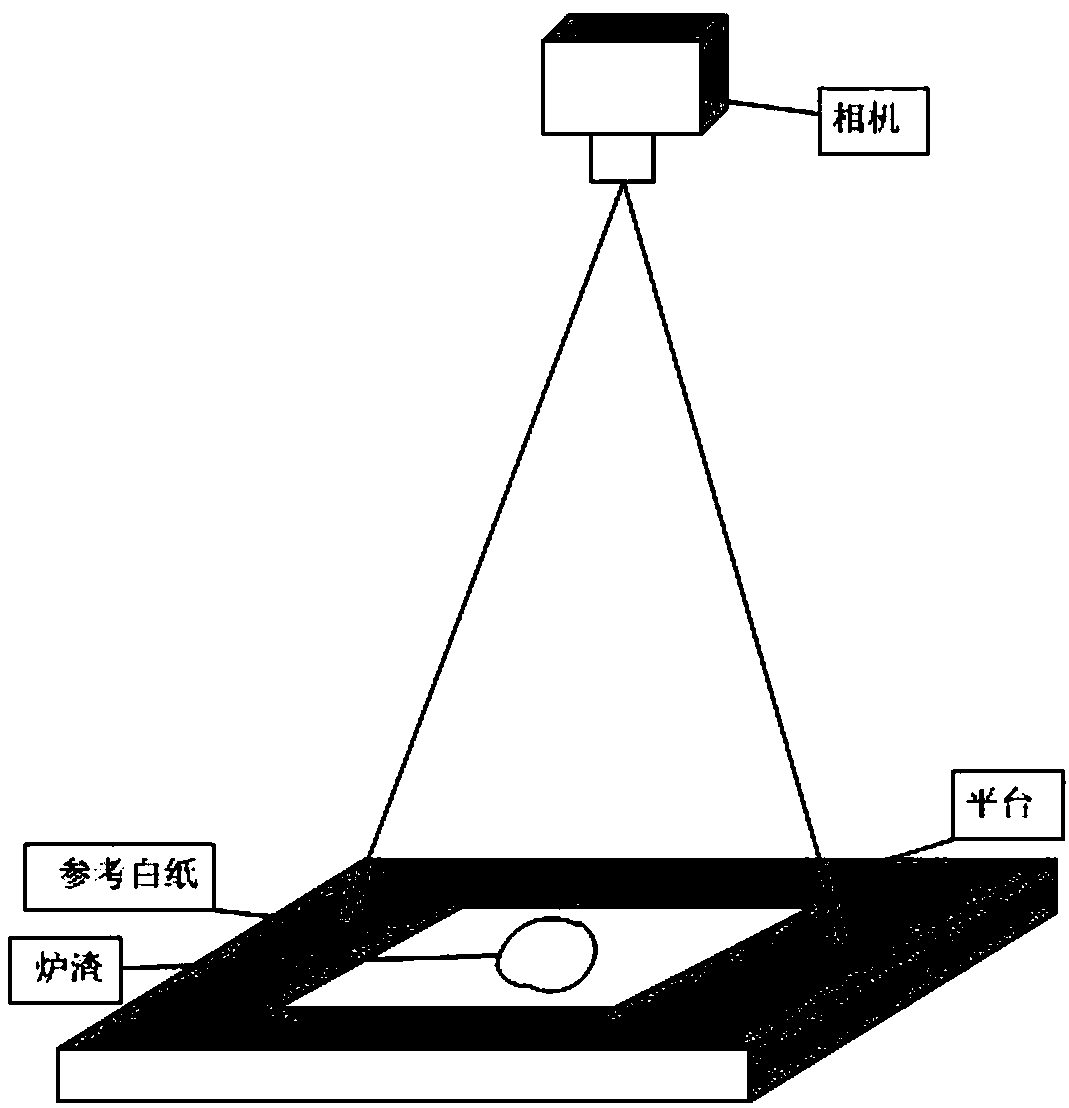

[0032] 2.1) If figure 2 As shown, after building the imaging device, place any piece of flat and clean white paper with diffuse reflection characteristics in the imaging range as a reference object, and adjust the aperture or expos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com