A kind of reagent mixing device and method

A reagent and mixing technology, which is applied in the field of medical devices, can solve the problems of long time for placing reagent bottles and high operation requirements, and achieve the effects of avoiding test result errors, reducing operation difficulty, and reducing placement error rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

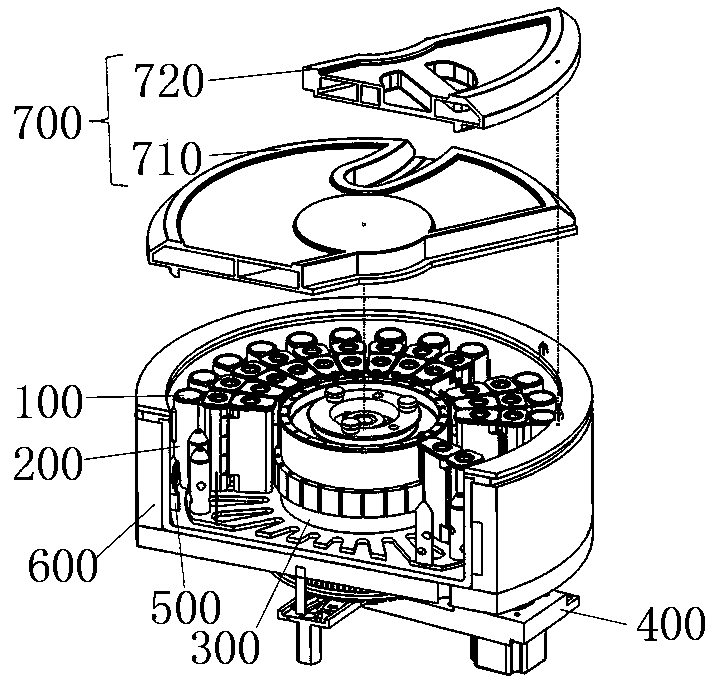

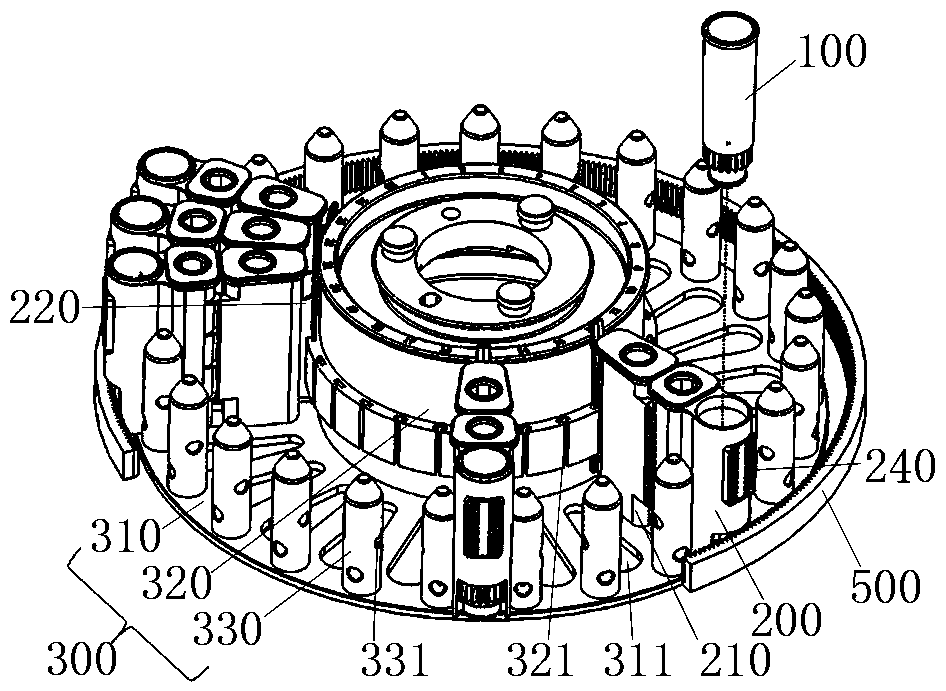

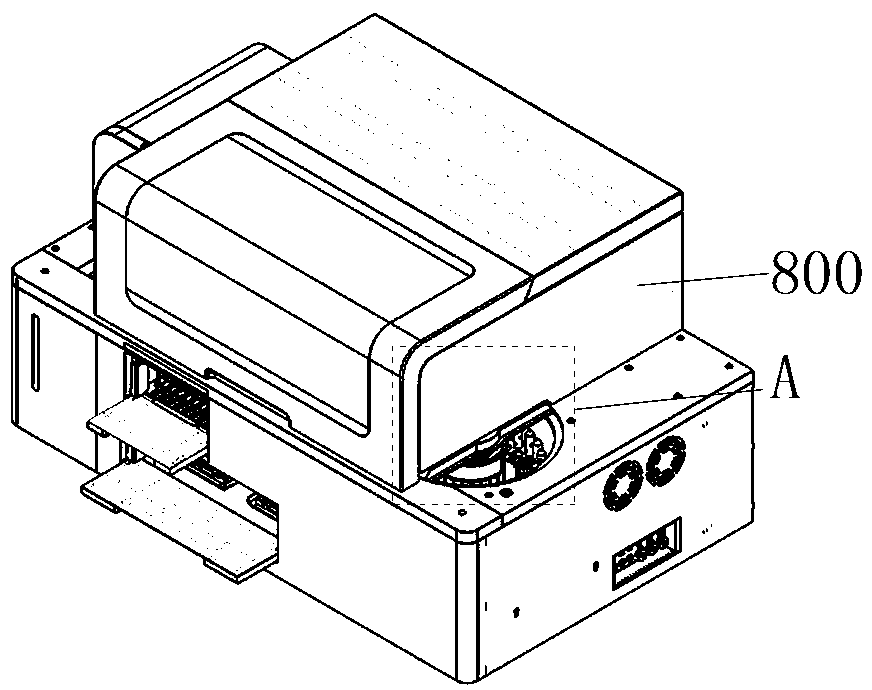

[0032] see also Figure 1-Figure 2 , a reagent mixing device, comprising: a reagent bottle 100 for holding the reagent to be mixed, a reagent bottle base 200 for loading the reagent bottle 100, for carrying and fixing several reagent bottle bases 200 A support device 300, a drive device 400 disposed on the support device 300 for driving the support device 300 to rotate, and a C-shaped mixing mechanism 500 disposed around the support device 300; the reagent bottle 100 can be The mixing mechanism 500 rotates under the drive. It also includes: a reagent chamber body 600 for accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com