Double helix push type waste powder collection device

A collection device and push-type technology, which is applied in the field of laser printer waste powder recovery equipment, can solve the problems of lowering the process level, complex structure, and printing quality decline, and achieve the effects of high cleaning efficiency, good sealing effect, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

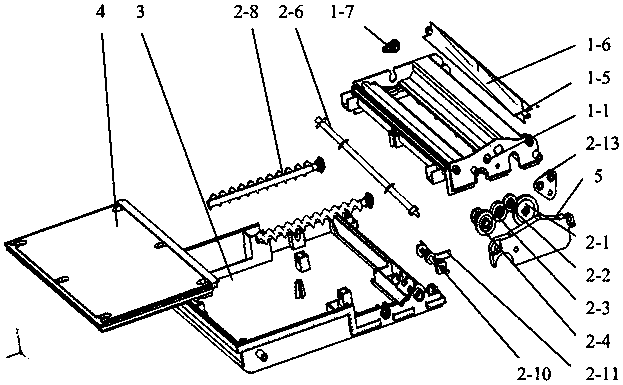

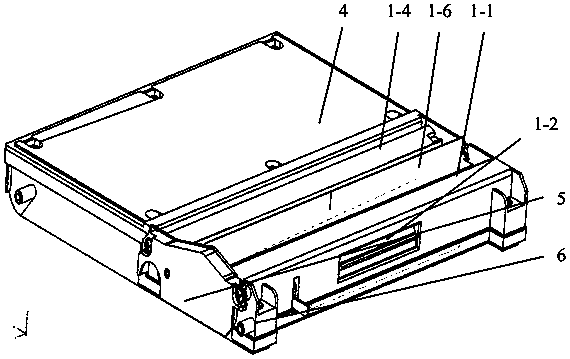

[0035] like figure 1 As shown, this embodiment provides a double-screw propulsion type waste powder collection device, including a bottom case 3, a main support unit 1 and a transmission unit 2; the main support unit 1 includes a main support 1-1, a powder drop port 1-3 and The powder scraping shaft 1-5, the main bracket 1-1 is fixed on the bottom shell 3, the powder dropping port 1-3 is set at the middle end of the main bracket 1-1, and the side of the powder dropping port 1-3 is provided with a ramp 1-4, It is used to import printing waste powder. The scraper shaft 1-5 is set above the powder drop port 1-3. The scraper shaft 1-5 is equipped with a scraper 1-6, which is used to remove the waste on the ramp 1-4. The powder is scraped off; the connection between the powder scraping shaft 1-5 and the main support 1-1 is provided with a right bushing 2-13 for fixing the other end of the powder scraping shaft 1-1.

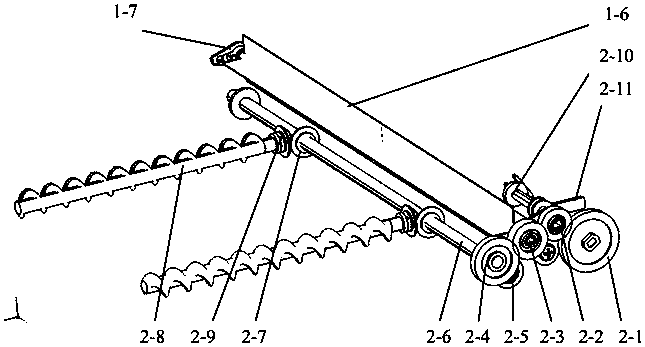

[0036] like figure 2 , 3 As shown, the transmission unit 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com