Material stripping structure and automatic material loading machine

An automatic feeding and stripping technology, applied in electrical components, electrical components, etc., can solve problems such as damage, cracks, and inability to peel and transport FPC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

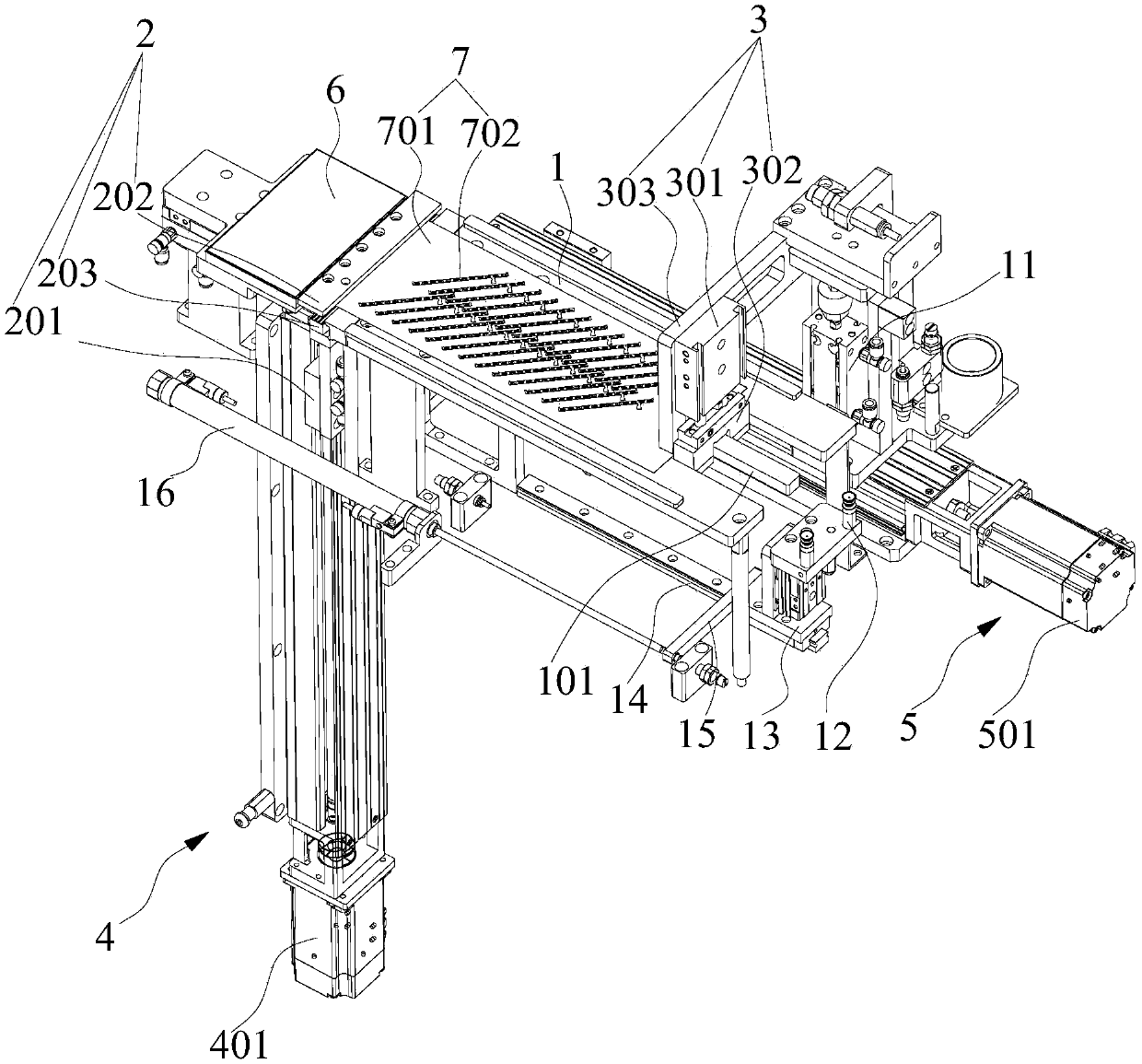

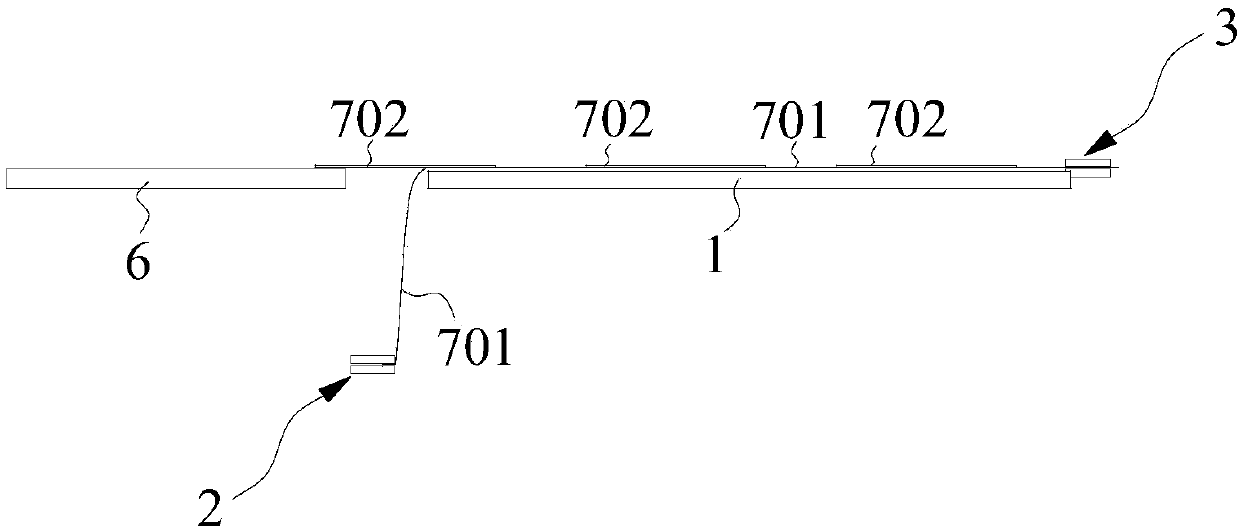

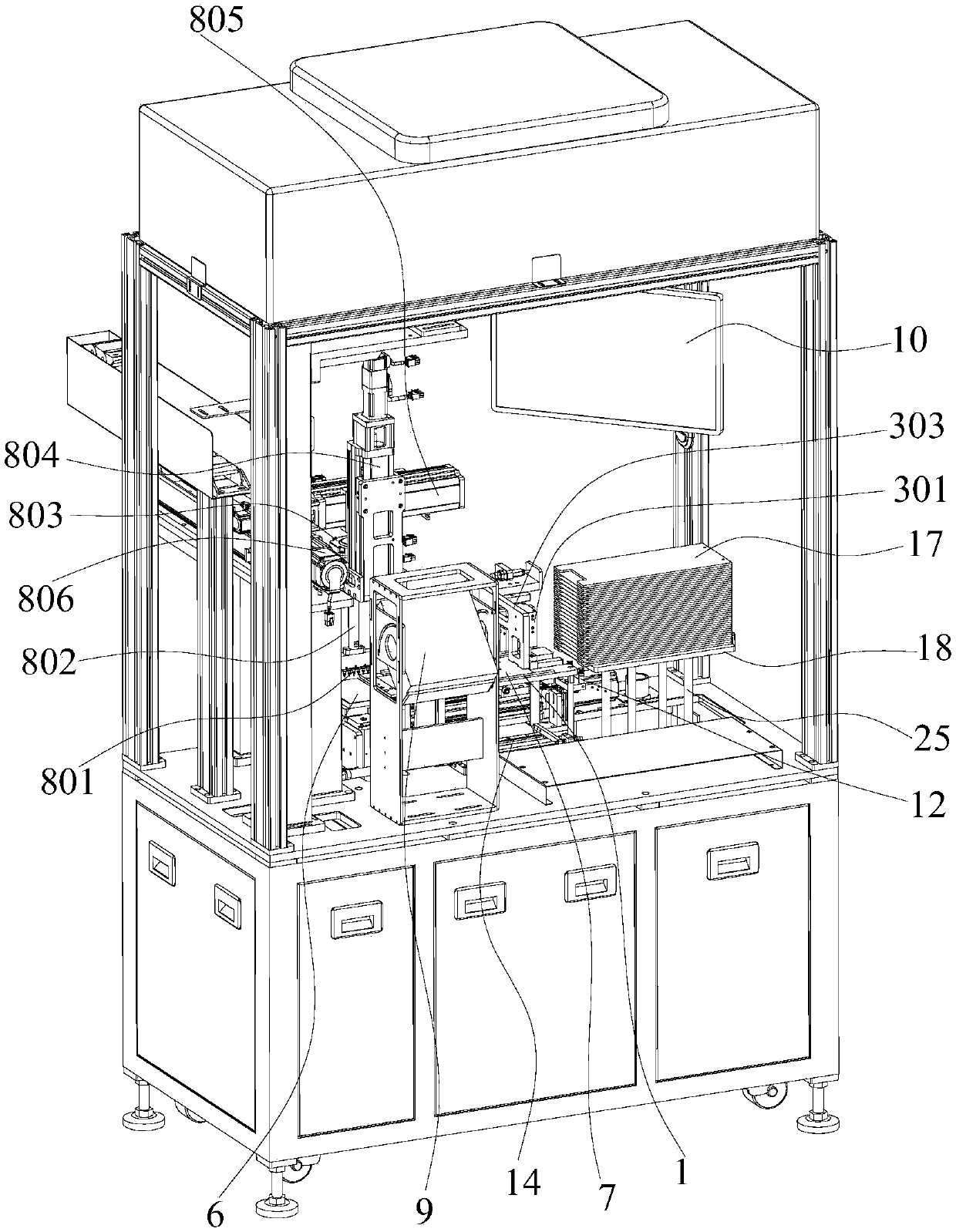

[0034] Further, see figure 1 , as a specific embodiment of the stripping structure provided by the present invention, the front clamp 2 includes a first cylinder 201, a first front splint 202 connected to the movable end of the first cylinder 201, and a fixed end connected to the first cylinder 201. The second front splint 203. Specifically, the first cylinder 201 drives the movement of the first front splint 202 to realize the change of the distance between the first front splint 202 and the second front splint 203, thereby realizing the cooperation between the first front splint 202 and the second front splint 203 The diaphragm 701 is clamped or loosened. Certainly, the connection mode between the first front splint 202 , the second front splint 203 and the movable end or the fixed end of the first cylinder 201 can be adjusted according to needs, and there is no unique limitation here.

[0035] Further, see figure 1 , as a specific embodiment of the stripping structure pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com