One-finger angular pneumatic gripper and respective manufacturing method

A technology of pneumatic clamps and jigs, which is used in the manufacture of tools, chucks, workpiece clamping devices, etc., can solve problems such as fracture and loss of pneumatic sealing, and achieve the effect of maximizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

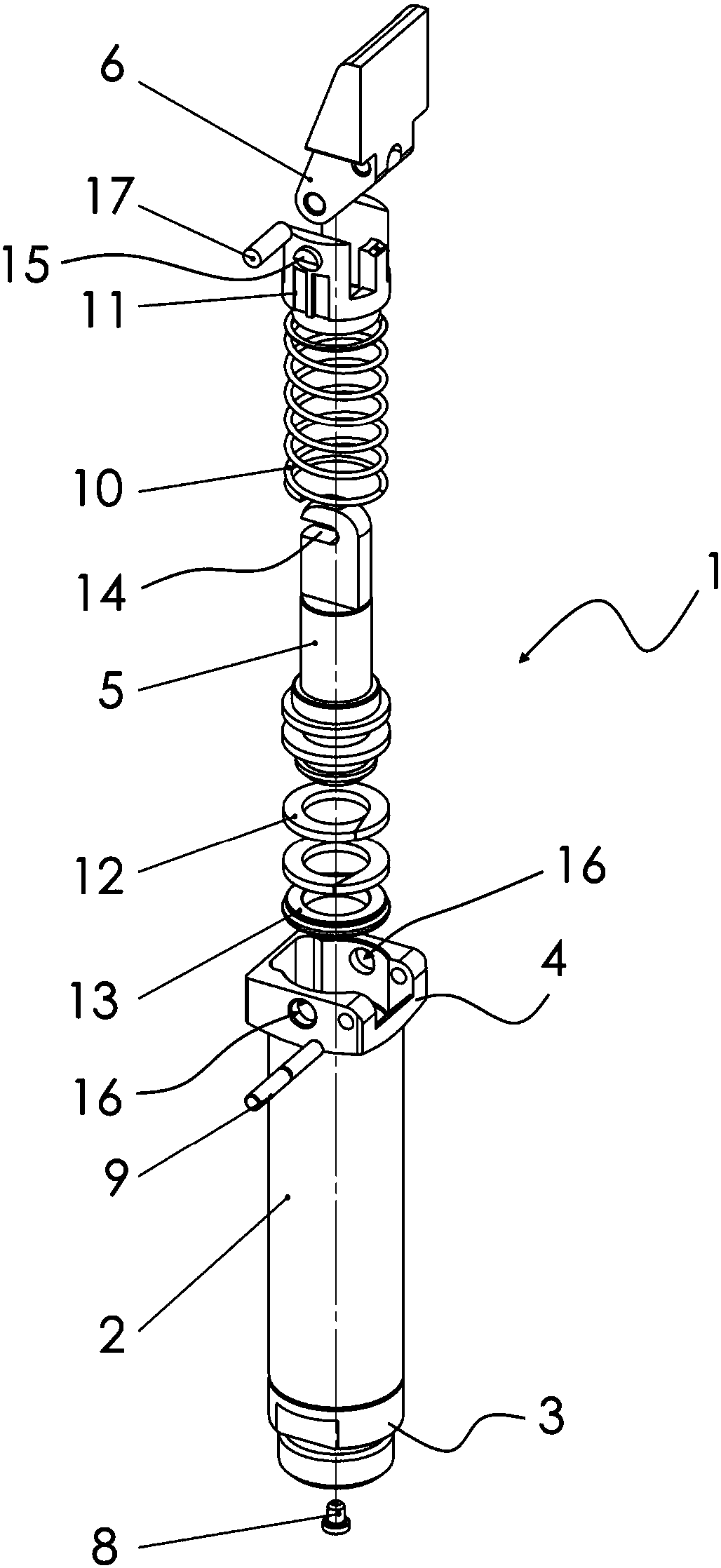

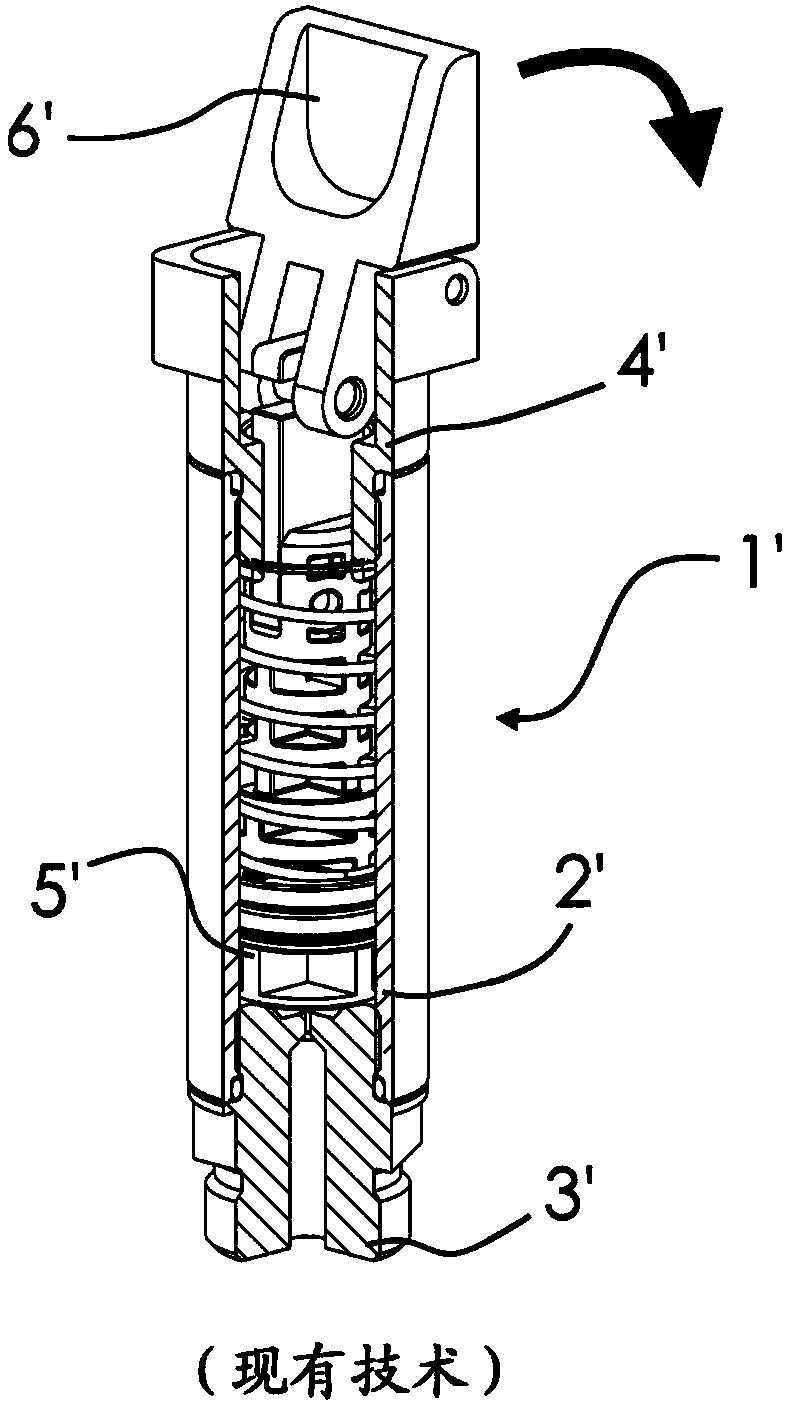

[0031] figure 1 A single-finger pneumatic gripper 1' according to known technology is shown. As mentioned above, this clamp 1' comprises a main body 2' which is generally an aluminum tube 2' with threaded ends. These ends are closed by respective plastic ring nuts 3' and 4' threaded to the body 2' of the clamp. The duct runs through the first ring nut 3', allowing compressed air to enter the body 2', said first ring nut 3' being figure 1 One of the lower ring nuts. A piston 5' is slidingly inserted into the body 2' to define a cylinder-piston coupling. Single clamping finger 6' hinged to second ring nut 4'— figure 1 the upper one of the ring nuts—and is connected to the piston in such a way that, according to the direction indicated by the arrow, the drive clamping finger is figure 1 Rotation between an open position shown and a closed position not shown.

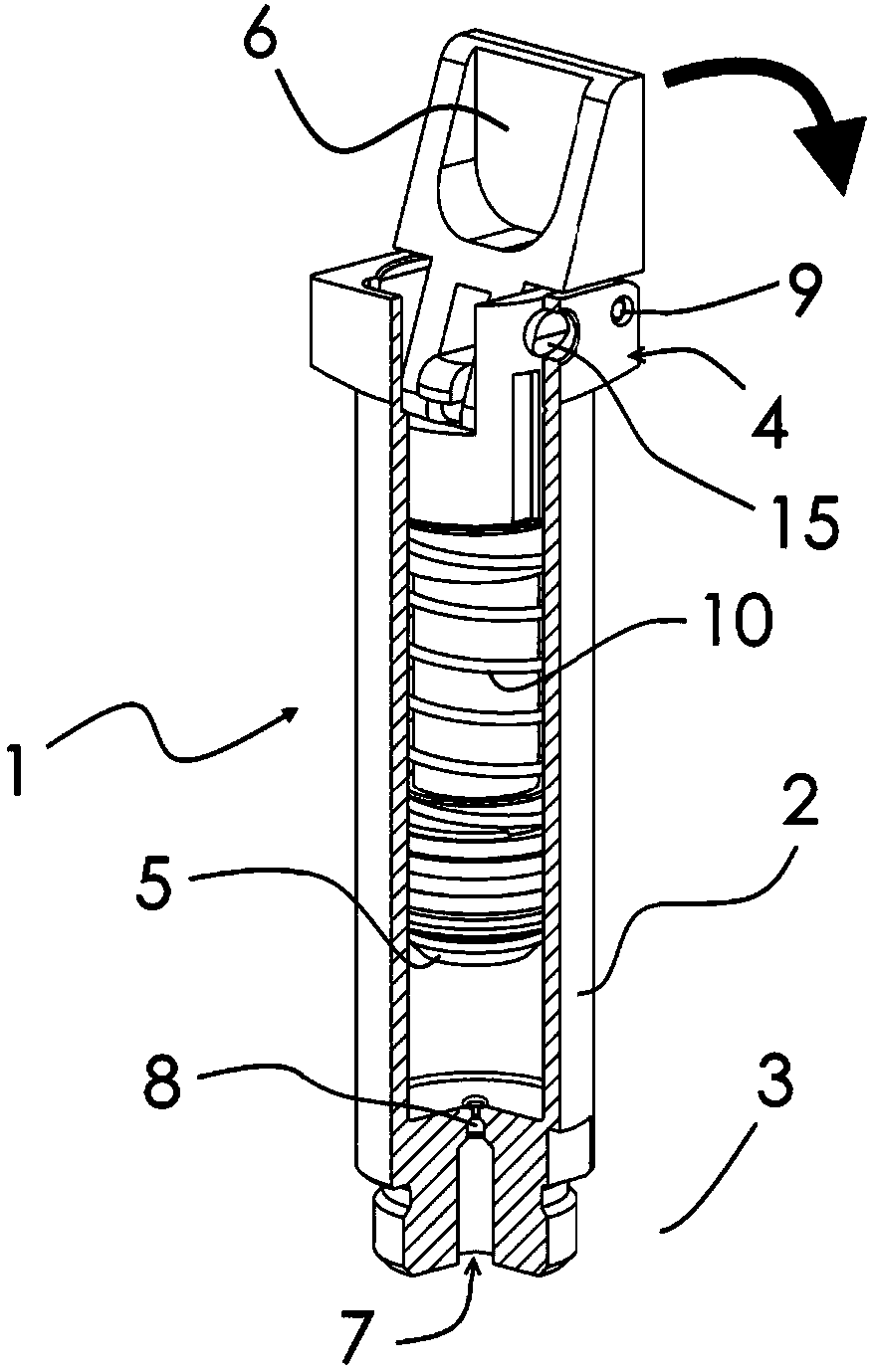

[0032] figure 2 An embodiment of a clamp 1 according to the invention is shown. Unlike the solutions according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com