Film covering head of curved-surface film pasting mechanism

A technology of film sticking mechanism and curved surface, which is applied in the field of film covering head, can solve the problems such as the inability to complete the action of film sticking on curved display screens, and achieve the effect of fully automatic film sticking process and realization of film sticking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

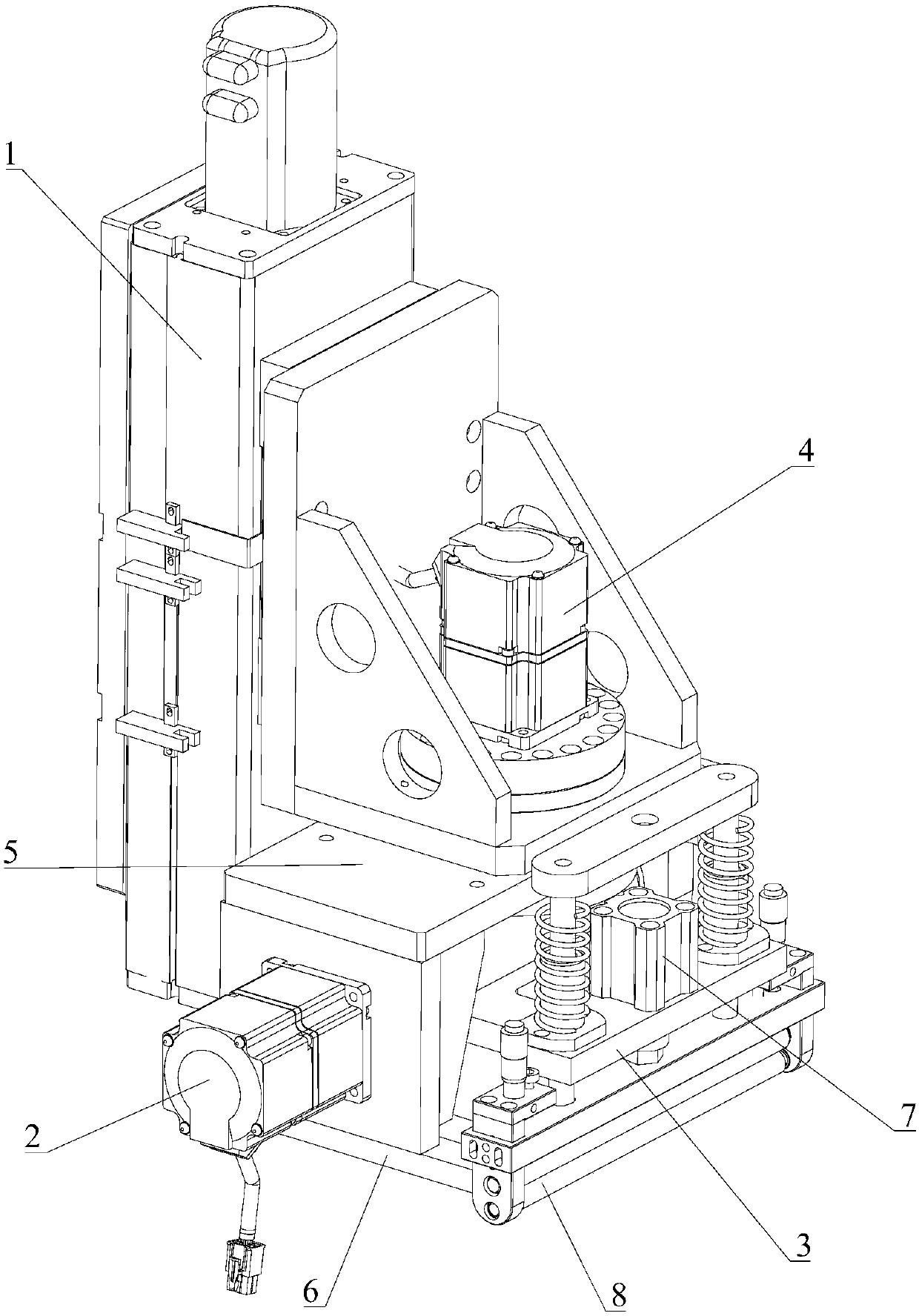

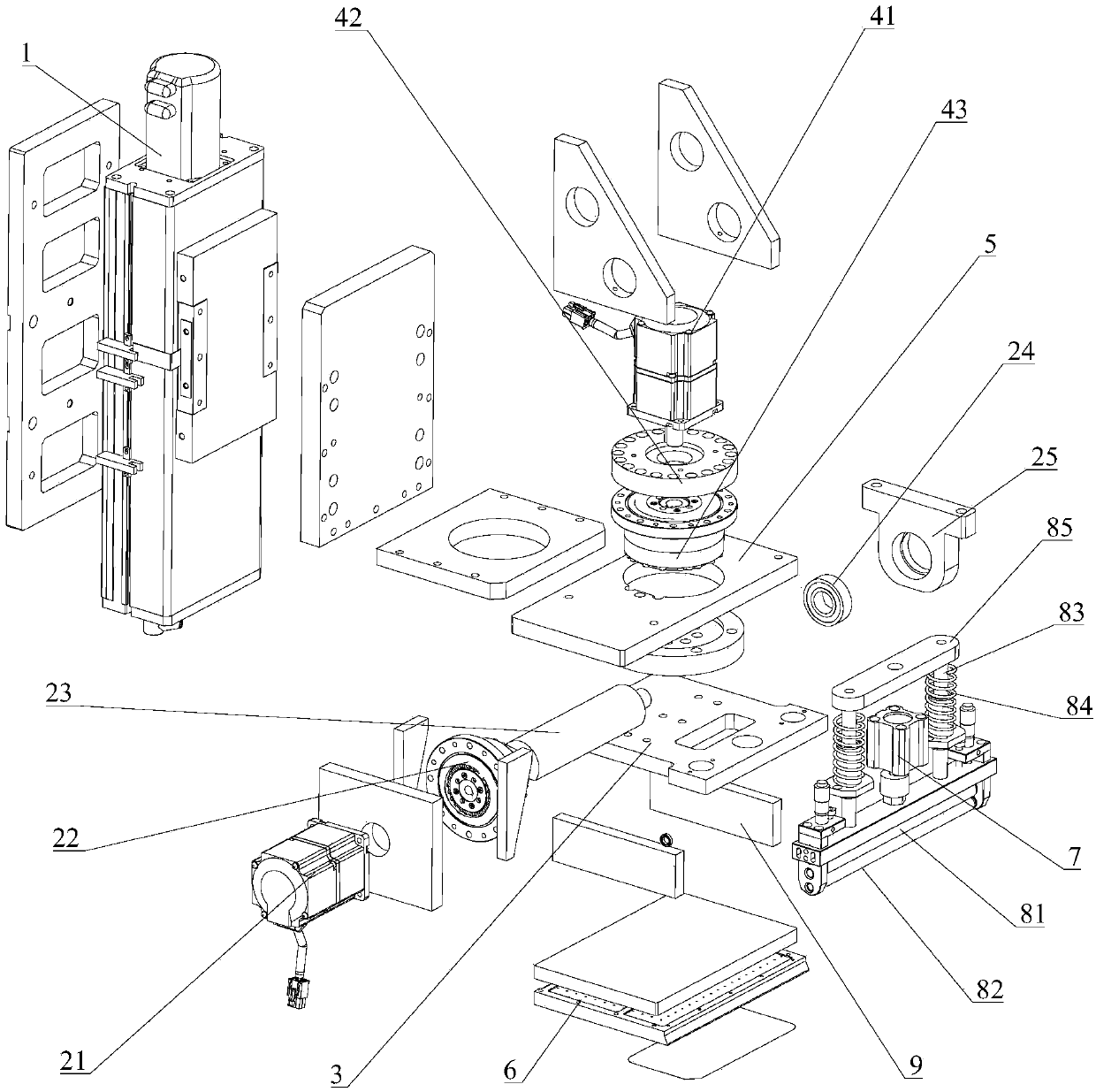

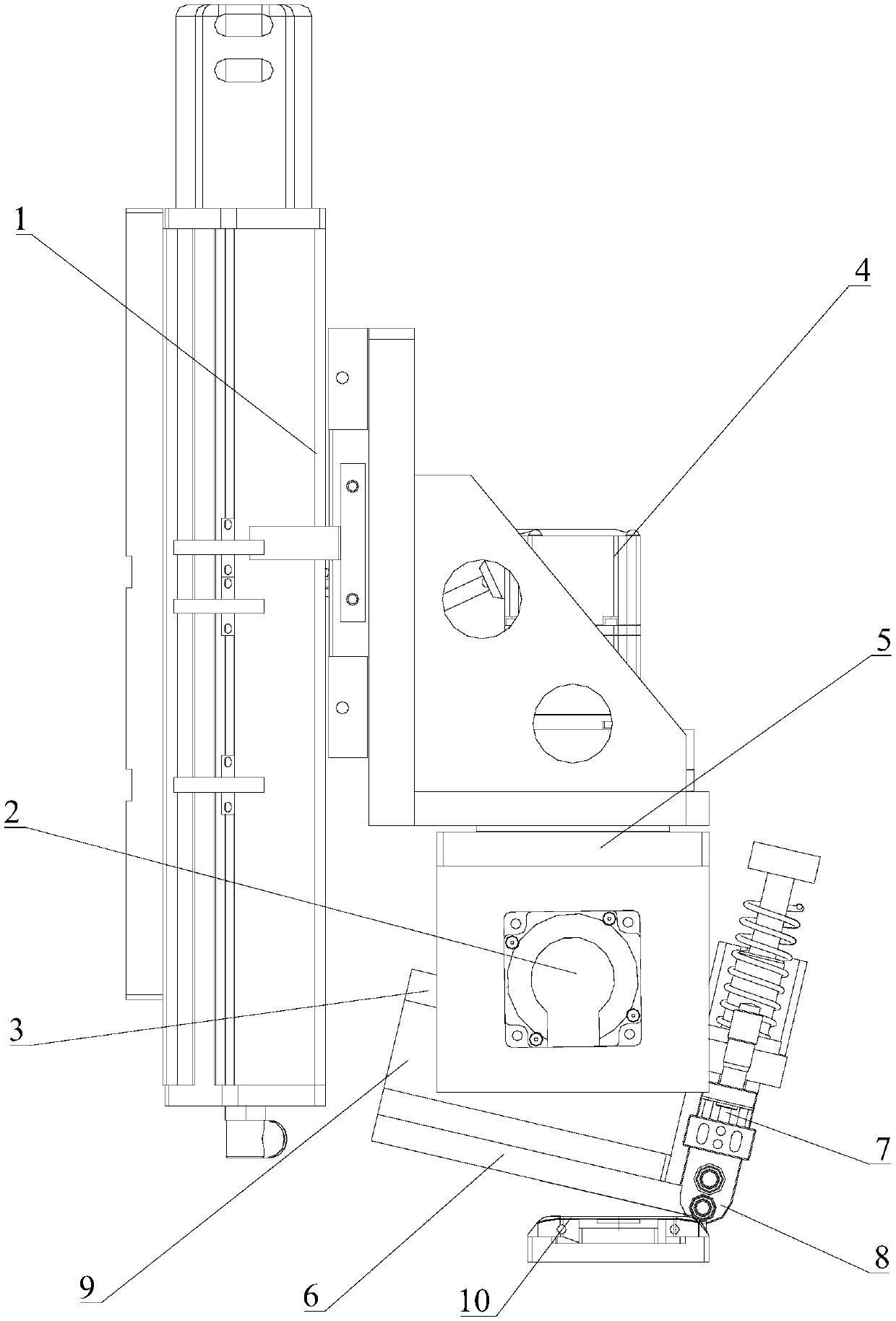

[0047] Please refer to figure 1 with figure 2 , Embodiment 1 of the present invention is: a laminating head of a curved surface film sticking mechanism, which is used to stick a film on a curved display screen 10 on a bonding plane (on the bonding plane, the curved edge of the curved display screen 10 is aligned with X axis parallel). The laminating head of the curved surface film sticking mechanism mainly includes an X-axis translation component, a Y-axis translation component, a Z-axis lifting component 1, a first rotation component 2, a first connecting plate 3, a second rotating component 4, a second connecting plate 5, The film suction plate 6 and the cylinder pressing down assembly, wherein the X-axis translation assembly and the Y-axis translation assembly are not shown in the figure. The Y-axis translation component is connected to the X-axis translation component and drives the X-axis translation component to move along the Y-axis direction; the X-axis translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com