Outer ship hull protective coating and application method thereof

A protective coating and coating technology, applied in the direction of coating, hull, ship construction, etc., can solve the problem of not being able to protect the outer hull for a long time, and achieve the effect of improving adhesion and corrosion resistance, and avoiding seawater corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

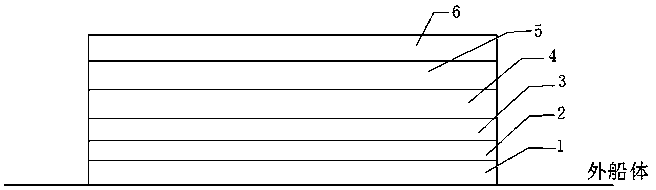

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The protective coating for the outer hull of a ship and the application method thereof of the present invention comprise a grease-decomposing agent coating 1, a phenylsilane coupling agent coating 2, an acrylic resin coating 3, an aramid staple fiber coating 4 and a polysiloxane coating 5. Grease decomposition agent coating 1 is coated on the outer hull, and the grease decomposition agent coating 1 is first coated on the outer hull to play the function of cleaning the grease on the surface of the outer hull; the phenylsilane coupling agent coating 2 is coated on the On the grease decomposition agent coating 1, the second step is to coat the phenylsilane coupling agent coating 2, which can improve the adhesion and corrosion resistance of the subsequent coating; the acrylic resin is coated on the phenylsilane coupling agent coating 2, The acrylic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com