Multistage multimode mechanical and hydraulic continuously variable transmission

A continuously variable transmission, mechanical transmission technology, applied in mechanical equipment, fluid transmission, belt/chain/gear, etc., to achieve the effect of flexible switching control, maintaining stability, and improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

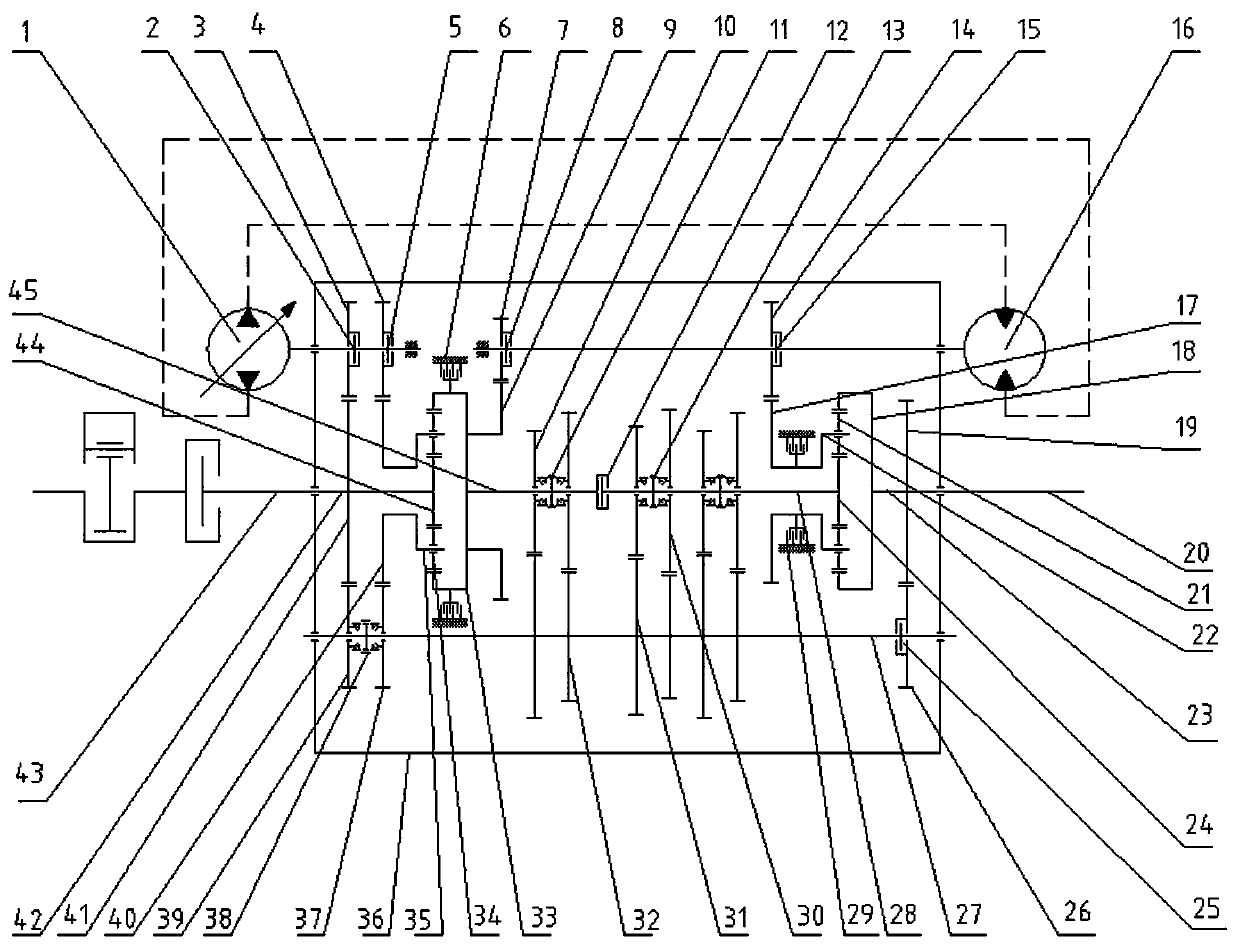

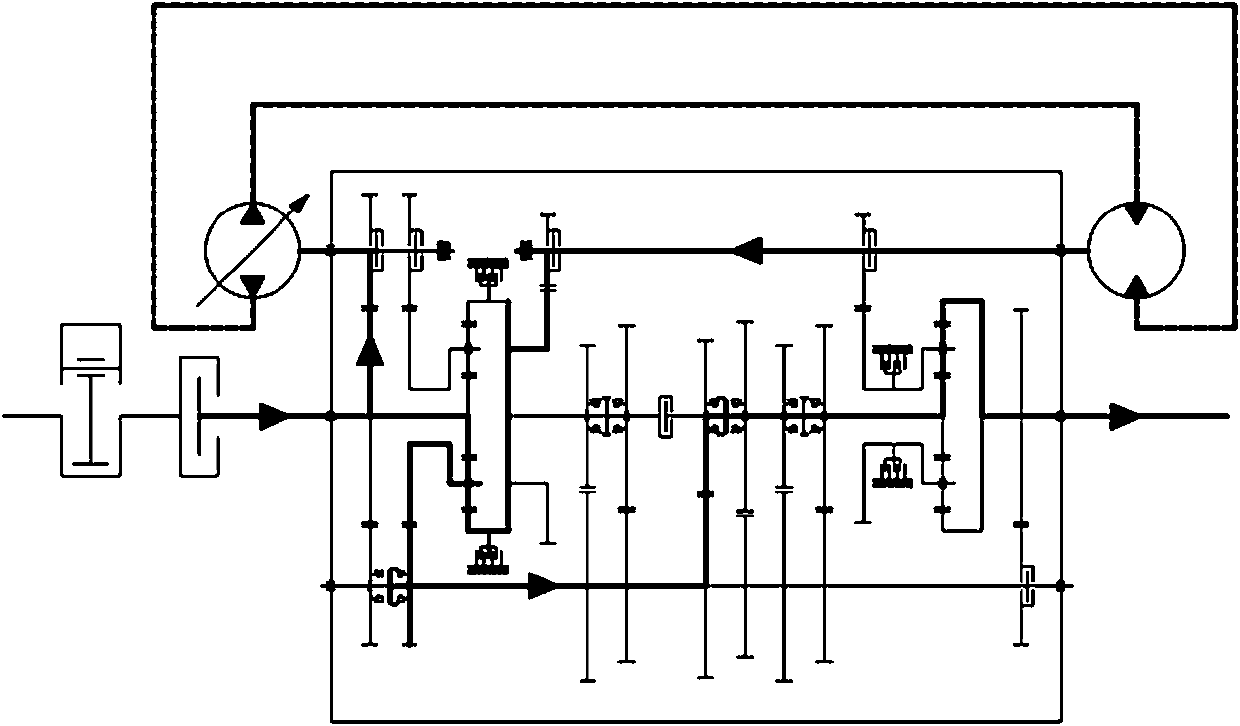

[0034] Embodiment 1. The first hydromechanical diversion and confluence form of a multi-stage multi-mode mechanical and hydraulic continuously variable transmission: the power is diverted at the thirteenth gear 3 and the first gear 41, and the confluence is realized at the front planetary row. The final power passes through the rear planetary row to output power. Specifically, such as figure 2 As shown, the power transmitted from the engine realizes torque splitting at the first gear 41, all the way through the thirteenth gear 3 and the engaged first clutch 2 to the variable displacement hydraulic pump 1, and then through the hydraulic pipeline, quantitative The hydraulic motor 16, the third clutch 8, the fifteenth gear 7 and the third gear 9 transmit power to the front ring gear 33 of the front planetary row; one way transmits power to the front sun gear 44; The speed confluence is realized by the row, and the power after confluence passes through the third gear 9, the firs...

Embodiment 2

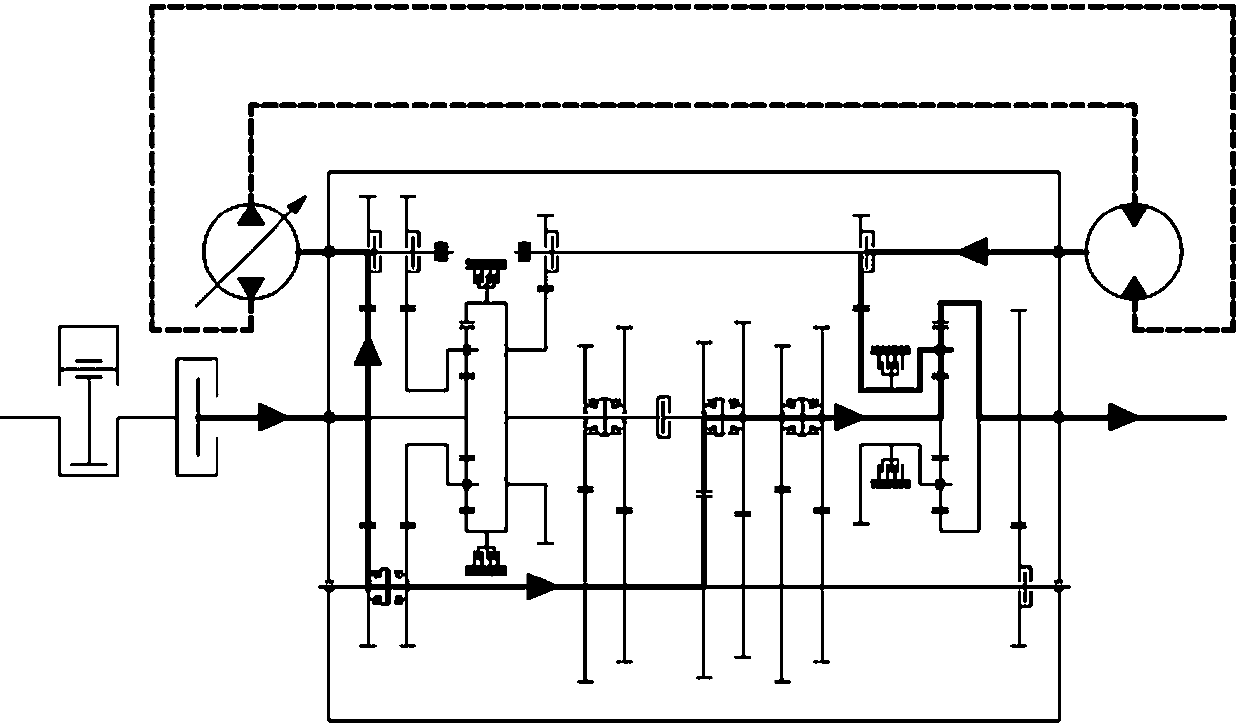

[0038] Embodiment 2. A second type of hydromechanical branching and converging form of a multi-stage multi-mode mechanical and hydraulic continuously variable transmission: the power realizes torque splitting at the thirteenth gear 3, the first gear 41 and the eighth gear 39, and passes through the hydraulic circuit 1. The speed confluence is realized at the rear planetary row, and the power is output through the main output shaft 20 after the confluence. Specifically, such as image 3 As shown, the power transmitted from the engine realizes torque splitting at the first gear 41, all the way through the thirteenth gear 3 and the closed first clutch 2 to the variable displacement hydraulic pump 1, and then through the hydraulic pipeline, quantitative The hydraulic motor 16, the fourth clutch 15, the sixteenth gear 14 and the sixth gear 17 transmit power to the rear planetary carrier 22 of the rear planetary row; all the way through the eighth gear 39 and the first synchronizer ...

Embodiment 3

[0042] Embodiment 3. The third hydromechanical diversion and confluence form of a multi-stage multi-mode mechanical and hydraulic continuously variable transmission: the power is diverted at the front planetary row, and the confluence is realized at the rear planetary row through the hydraulic circuit. After converging, it passes through the main output Shaft 20 outputs power. Specifically, such as Figure 4 As shown, the power transmitted from the engine realizes torque splitting at the front planetary row, all the way through the fourteenth gear 4 and the closed second clutch 5 to the variable displacement hydraulic pump 1, and then through the hydraulic pipeline, quantitative hydraulic pressure The motor 16, the fourth clutch 15, and the sixteenth gear 14 transmit power to the rear planetary carrier 22 of the rear planetary row; all the way through the ninth gear 37 and the first synchronizer 38 to the transmission gear shaft 27, and then through one of them in turn The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com