Optical axis alignment device and method based on camera imaging

A camera imaging and alignment device technology, which is applied in the field of optical engineering, can solve problems such as the inability to balance easy operation and alignment accuracy, and achieve the effect of easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

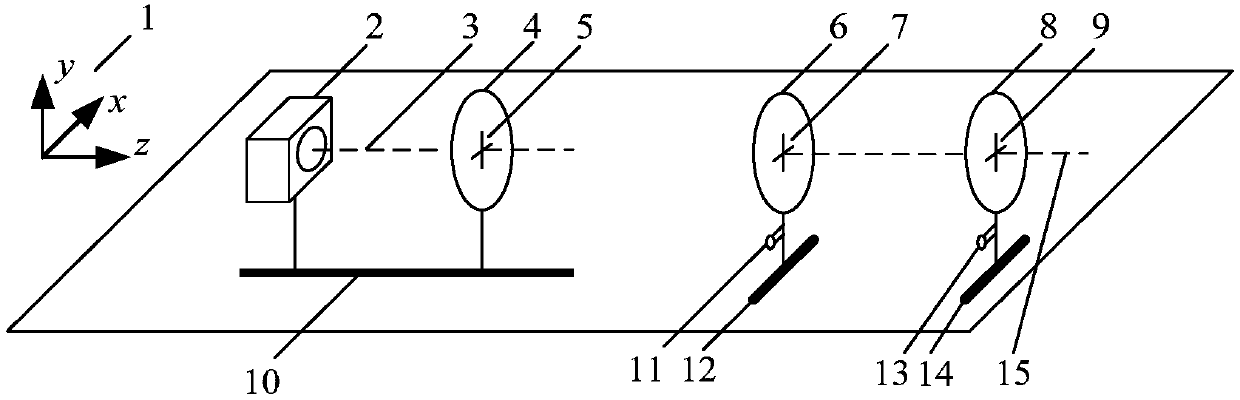

[0030] see figure 1 , the present invention provides an optical axis alignment device based on camera imaging and an optical axis alignment method. The structure of the preferred embodiment of the optical axis alignment device includes No. 1 guide rail 10, No. Guide rail 12 and No. 3 guide rail 14, No. 2 guide rail 12 is parallel to No. 3 guide rail 14 and perpendicular to No. 1 guide rail 10;

[0031] Camera 2 and No. 1 reticle 4 are installed on the No. 1 guide rail 10, No. 2 reticle 6 is installed on No. 2 guide rail 12, and No. 3 reticle 8 is installed on No. 3 guide rail 14; Camera 2 can select SLR camera for use, one No. reticle 4, No. 2 reticle 6 and No. 3 reticle 8 are cross reticles.

[0032] The camera 2 can slide freely along the No. 1 guide rail 10, the No. 1 reticle 4 is fixedly installed on the No. 1 guide rail 10, and the optical axis where the cross center 5 of the No. 1 reticle and the camera lens center is located is the fixed optical axis 3;

[0033] No. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com