Internal cooling fiber vibrating wire grid type centrifugal demister

A kind of technology of fiber grid and mist eliminator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

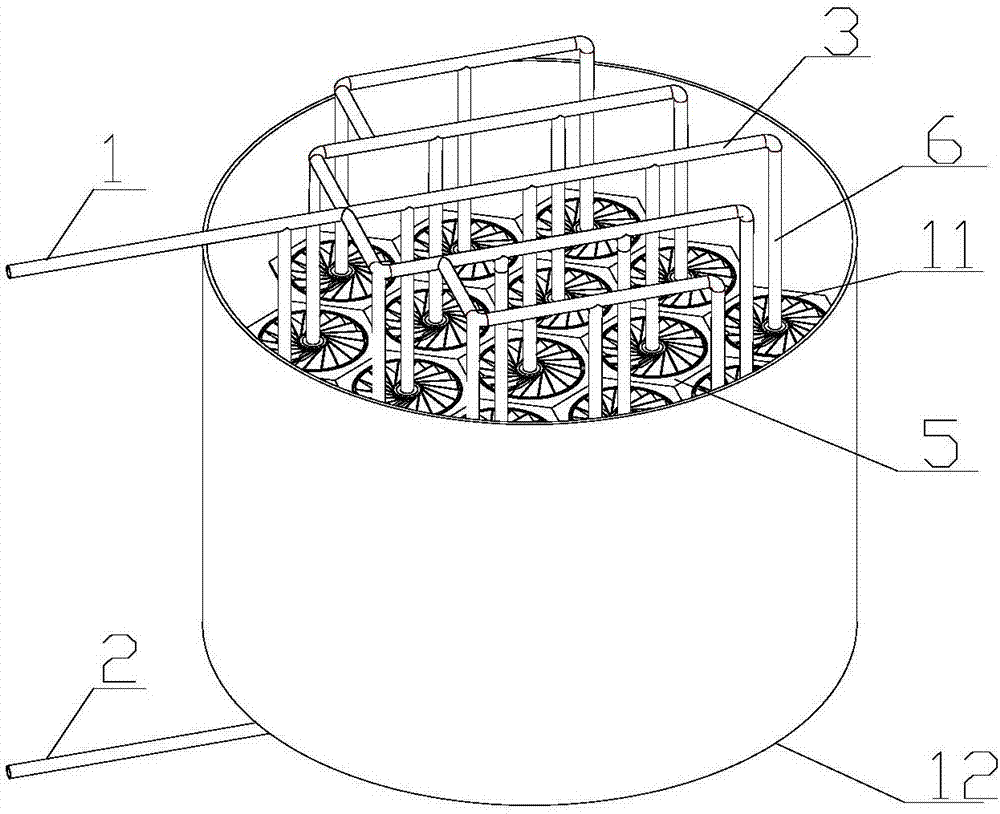

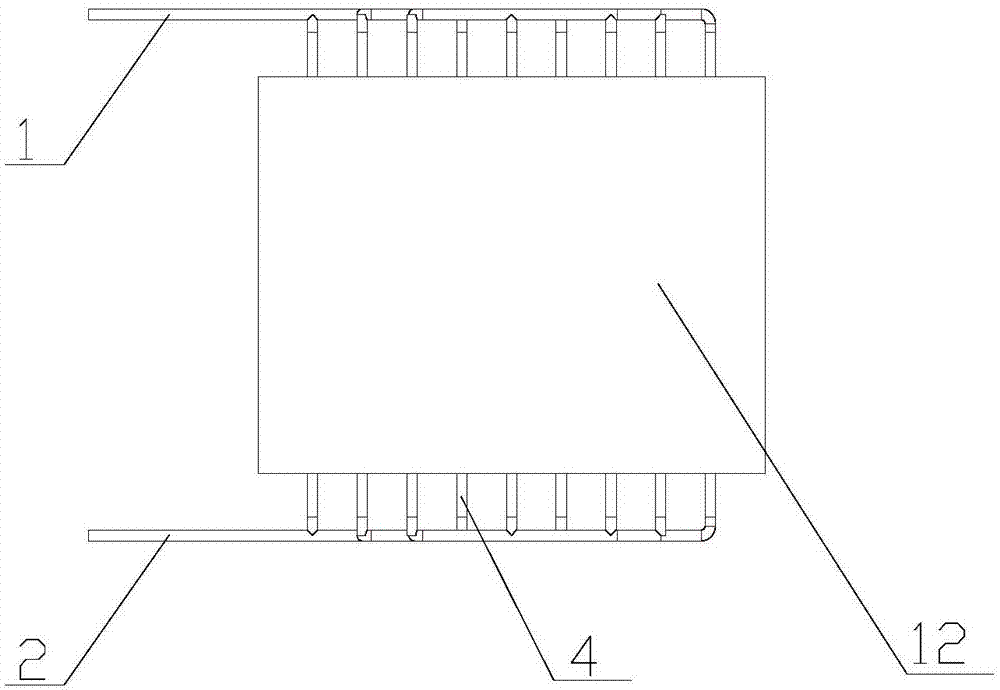

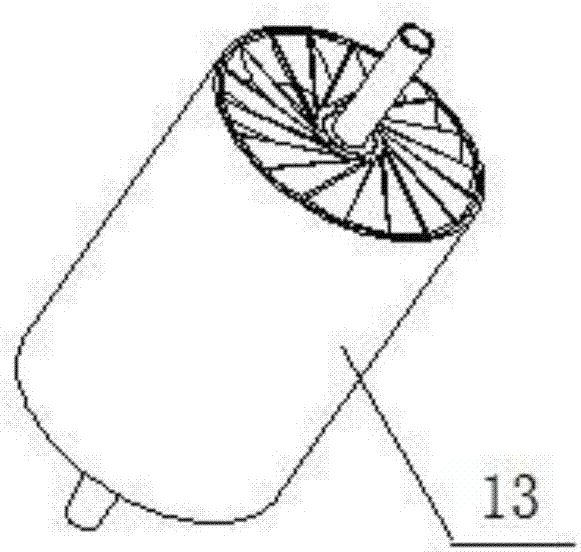

[0024] The main structure of the internal cooling fiber vibrating wire grid type centrifugal demister involved in this embodiment includes an air inlet pipe 1, an air outlet pipe 2, an air distribution pipe 3, an air collection pipe 4, a support plate 5, a cooling water pipe 6, and a demister unit 13 And the first cylinder 12, the first cylinder 12 is vertically provided with a plate-shaped support plate 5, the size and structure are the same and adjacent support plates 5 are connected end to end to form a hollow prism structure, and more than one size structure is the same The hollow prisms form a honeycomb structure, and each hollow prism is equipped with a defogging unit 13. The defogging unit 13 includes a first bearing 7, a second bearing 8, a first fiber grid impeller 9, and a second fiber grid impeller. 10 and the second cylinder 11, the center of the second cylinder 11 is vertically provided with a cooling water pipe 6, the input end of the cooling water pipe 6 is conne...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that: the angle between the blades 14 of the first fiber grid impeller 9 and the horizontal direction is 40°-50°, and the optimal angle is 45°; the second fiber grid impeller 10 The included angle between the blades 14 and the horizontal direction is 130°-140°, and the optimal included angle is 135°; the specific defogging process steps and implementation of the internally cooled centrifugal fiber vibrating wire grid type mist eliminator device involved in this embodiment Example 1 is the same.

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is that: the number of blades of the first fiber grid impeller 9 and the second fiber grid impeller 10 is the same, the number of blades is 15-25, and the optimal choice is 18; this embodiment The specific demisting process steps of the internally cooled centrifugal fiber vibrating wire grid demister device are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap